Abstract

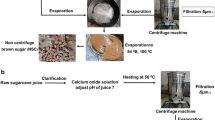

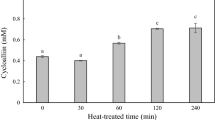

Non-Centrifugal Sugar commonly known as jaggery is a famous sweetening agent derived from sugarcane juice. The sugarcane juice undergoes enzymatic reactions during jaggery production, resulting in the darkening of its color. The study presents enzymatic inactivation of sugarcane juice, which was extracted from blanched sugarcane stalks and also the effect of organic clarificants on the quality of jaggery. Blanching of sugarcane stalks at 80 °C for 5 min inhibited enzymatic browning up to 53–55%. Clarification of juice was carried out using organic clarificants such as aloe vera leaf extract, moringa leaf extract at 0.1%, 0.2% and 0.3% v/v concentrations and chemical clarificant (Hydros). The jaggery prepared using organic clarificants, either using aloe vera or moringa leaf extract at 0.3% concentration was found to be superior in terms of insoluble solids, sucrose content, total phenols and total flavonoids. The jaggery prepared using chemical clarificants is brighter in color with low microbial load, however, it is inferior in quality parameters such as total phenols and flavonoids compared to jaggery prepared using organic clarificants. Hence, the technology of jaggery making from blanched canes using organic clarificants may be recommended as an alternative to chemical clarification to produce organic jaggery rich in bioactive compounds.

Similar content being viewed by others

References

American Public Health Association (APHA). 2001. Culture methods for enumeration of microorganisms. In Compendium of methods for the microbiological examination of foods, ed. P.D. Frances and I. Keith, 53–67. Washington, DC: APHA.

Anonymous. 2011. Acharya N.G. Ranga agricultural university, annual report.

AOAC. 1990. Official methods of analysis, 15th ed. Washington, DC: Association of Official Analytical Chemist.

Baboo, B., and S. Solomon. 1995. Nutritive sweeteners from sugar crops: development of jaggery khandsari and syrup industry in India. In Sugarcane agro-industrial alternatives, ed. G.B. Singh and S. Solomon, pp. 289–312. New Delhi: IBH Publishing Co Pvt Ltd.

Bureau of Indian standards IS 12923, (Clause 4.3 and 6.1). 1990. New Delhi, India.

Chang, C.C., M.H. Yang, H.M. Wen, and J.C. Chern. 2002. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. Journal of Food and Drug Analysis 10 (3): 178–182.

Chauhan, D.V.S. 1972. Vegetable production in India, 3rd ed., 28–30. Agra: Ram Prasad and Sons.

Chauhan, A.K., S. Sharma, P. Sharma, and R. Maheshwari. 2012. Production of organic sugar employing vegetable agent for sugarcane juice. International Journal of Institutional Pharmacy and Life Sciences 2 (2): 312–315.

Chikkappaiah, L.A.V.A., M.A.H. Nayaka, and P.K.G. Mahadeviah. 2017a. Preparation of plant mucilage clarificants and their effect on jaggery processing of sugarcane variety Co 86032. International Journal of Pharmacy and Pharmaceutical Sciences 9: 32–36.

Chikkappaiah, L.A.V.A., M.A.H. Nayaka, M.P. Manohar, and P. Kumar. 2017b. Effect of plant mucilage clarificants on physical and chemical properties of jaggery. International Journal of Recent Scientific Research 8 (10): 20663–20669.

Christaki, E.V., and P.C. Florou-Paneri. 2010. Aloe vera: A plant for many uses. Journal of Food Agriculture and Environment 8 (2): 245–249.

Costa, G.H.G., I.D.S. Masson, L.A.D. Freita, J.P. Roviero, and M.J.R. Mutton. 2014. Use of moringa oleífera lamarck leaf extract as sugarcane juice clarifier: Effects on clarified juice and sugar. Food Science and Technology 34: 204–209.

Dilip, P.A., A.S. Maruthi, and N.A. Charudatta. 2017. Techniques and advances in jaggery processing: A review. Research Journal of Chemical and Environmental Sciences 5 (2): 14–20.

Gangwar L.S., Solomon S., and Anwar S.I. 2015. Technological and policy options for modernization of jaggery industry in India. ICAR Policy Brief, 1–6. https://iisr.icar.gov.in/iisr/download/publications/report/policypaper_gangwar.pdf.

Henshall, J.D. 2012. Food safety and standards authority of India ministry of health and family welfare government of India New Delhi. Manual of Methods of Analysis of Foods Fruit and Vegetable Products 5: 1–59.

Hussain, Z., M. Islam, Z. Mohammad, K.M. Khan, S. Perveen, and M. Afzal. 2012. The effect of pretreatment of juice on the properties and composition of jaggery. Sugar Tech 14: 291–294.

Jaffe, W.R. 2012. Health effects of non-centrifugal sugar (NCS): A review. Sugar Tech 14: 87–94.

Jittanit, W., S. Wiriyaputtipong, H. Charoenpornworanam, and S. Songsermpong. 2011. Effects of varieties, heat pretreatment and UHT conditions on the sugarcane juice quality. Chiang Mai Journal of Science 38 (1): 116–125.

Karthikeyan, J., and S.S. Samipillai. 2010. Sugarcane in therapeutics. Journal of Herbal Medicine and Toxicology 4 (1): 9–14.

Lambrecht, H.S. 1995. Sulfite substitutes for the prevention of enzymatic browning in foods. ACS Symposium Series 600: 313–323.

Lane, J.H., and L. Eynon. 1923. Methods for determination of reducing and nonreducing sugars. Journal of Science 42: 32–37.

Mao, L.C., Y.Q. Xu, and F. Que. 2007. Maintaining the quality of sugarcane juice with blanching and ascorbic acid. Food Chemistry 104 (2): 740–745.

McEvily, A.J., R. Iyengar, and W.S. Otwell. 1992. Inhibition of enzymatic browning in foods and beverages. Critical Reviews in Food Science & Nutrition 32 (3): 253–273.

Nayaka, H.M.A., L.A.V.A. Chikkappaiah, M.P. Manohar, and B.S. Gunashree. 2018. Storage studies of jaggery prepared using aloe vera, pursalane and malabar spinach mucilage clarificants. International Journal of Biosciences 13 (1): 196–205.

Nayaka, H.M.A., L.A.V.A. Chikkappalah, K.S. Venkatesh, B.S. Gunashree, and S. Sudharshan. 2018. Evaluation of bioactivity of jaggery prepared using plant mucilage as clarificant. Asian Journal of Pharmaceutical and Clinical Research 11: 294–299.

Nougbode, A.E.I., P. Sessou, A.K. Youssao, C.P. Agbangnan, D. Mama, and K.C.D. Sohounhloue. 2016. Evaluation de gel dAloevera en feuilles comme un floculant naturel: Criblage phytochimique et elimination de la turbidite des essais deau par coagulation flocculation. Research Journal of Recent Sciences 5 (1): 9–15.

Quispe, C., M. Villalobos, J. Borquez, and M. Simirgiotis. 2018. Chemical composition and antioxidant activity of aloe vera from the Pica Oasis (Tarapaca, Chile) by UHPLC-Q/Orbitrap/MS/MS. Journal of Chemistry 2018: 1–16. https://doi.org/10.1155/2018/6123850.

Rajesh, C.K., M.A. Shajahan, and S. Hameed. 2016. Analytical study of different samples of guda (jaggery) collected from Thrissur, Kerala. Ayurpharm: International Journal of Ayurveda and Allied Sciences 5: 52–58.

Ranganna, S. 1986. Manual of analysis of fruit and organic products, 2nd ed. New Delhi: Tata McGraw Hill Publishing Company Limited.

Rao, P.V.K., M. Das, and S.K. Das. 2007. Jaggery–a traditional Indian sweetener. Indian Journal of Traditional Knowledge 6: 95–102.

V.A. Shakunthala, and G. Devraj. 1991. Hibiscus abelmoschus L.-A vegetable clarificant in gur making. In National Seminar on Increasing Productivity, Quality and Storability of Jaggrey (gud) at Indian Institute of Sugarcane Research, Lucknow, India, 30th November–1st December.

Singh, J., S. Solomon, and D. Kumar. 2013. Manufacturing jaggery, a product of sugarcane, as health food. Agro Technology S11 (7): 1–3.

Singleton, V.L., R. Orthofer, and R.M. Lamuela-Raventos. 1999. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods in Enzymology 299: 152–178.

Sreedevi, P., L.E. Jayachandran, and P.S. Rao. 2018. Browning and bioactive composition of sugarcane juice (Saccharum officinarum) as affected by high hydrostatic pressure processing. Journal of Food Measurement and Characterization 12: 1962–1971.

Tomasik, P., M. Pałasinski, and S. Wiejak. 1989. The Thermal decomposition of carbohydrates. Part I. The decomposition of mono-, di and oligo-saccharides. Advances in Carbohydrate Chemistry and Biochemistry 47: 203–278.

Verma, V.K., and M. Narain. 1990. Moisture absorption isotherms of jaggery. Journal of Stored Products Research 26: 61–66.

Verma, P., N. Shah, and S. Mahajani. 2019. Effect of sodium hydrosulphite treatment on the quality of non-centrifugal sugar: Jaggery. Food Chemistry 299: 1–8.

Vongsak, B., P. Sithisar, S. Mangmool, S. Thongpraditchote, Y. Wongkrajang, and W. Gritsanapan. 2013. Maximizing total phenolics, total flavonoids contents and antioxidant activity of Moringa oleifera leaf extract by the appropriate extraction method. Industrial Crops and Products 44: 566–657.

Acknowledgements

The authors are grateful to ICAR for providing funds to AICRP on Post-Harvest Engineering and Technology and the Director of Research, Acharya N.G.Ranga Agricultural University for the encouragement and providing facilities to carry out the experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sreedevi, P., Madhava, M. Quality Improvement of Non-Centrifugal Sugar as Affected by Blanching and Organic Clarification. Sugar Tech 24, 1867–1876 (2022). https://doi.org/10.1007/s12355-022-01158-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01158-8