Abstract

Dextranase is commonly used for eliminating dextran contamination in sugar factory. This research, dextranase from Aspergillus allahabadii X26, was produced, purified and characterized including on dextran hydrolysis. A. allahabadii X26 was cultured in a medium containing 1% dextran T2000 as a carbon source in 5-l fermenter aerobically at 30 °C and obtain 110 U/ml crude extracellular dextranase activity within 9 days of incubation. Extracellular dextranase could be purified by the 2 steps of ammonium sulfate precipitation and affinity chromatography using Sephacryl S-300 HR. This resulted in 6.5-fold and a 39.1% recovery yield obtaining 3009 U/mg mg protein. The purified enzyme exhibited 66 kDa on SDS-PAGE and was specified as a glycoprotein. The optimum pH and temperature for enzyme activity were 5.8 and 55 °C, respectively. The enzyme exhibited thermostability in the range of 20–50 °C and pH 5–9 over the incubation period of 1.5 h. The dextranase activity was enhanced by Co2+, Mn2+ and Ca2+, whereas most ions and reagents did not inhibit its activity. The enzyme only had specificity to the α(1 → 6) glycosidic bond of dextran. Partial sequences of the enzyme determined by an ESI mass spectrometer showed similarity toward dextranase GH49. This purified dextranase (0.2 U/ml) from A. allahabadii X26 could degrade high molecular weight dextran into fragments of 5–10 kDa and oligodextrans within 5 min. These A. allahabadii X26 dextranase properties indicated high potential for dextran elimination in sugar production process.

Similar content being viewed by others

References

Abdel-Rahman, E.A., Q. Smejkal, R. Schick, S. El-Syiad, and T. Kurz. 2008. Influence of dextran concentrations and molecular fractions on the rate of sucrose crystallization in pure sucrose solutions. Journal of Food Engineering 84 (4): 501–508.

Arnold, W.N., T.B. Nguyen, and L.C. Mann. 1998. Purification and characterization of a dextranase from Sporothrix schenckii. Archives of Microbiology 170 (2): 91–98.

Bejar, W., V. Gabriel, M. Amari, S. Morel, M. Mezghani, E. Maguin, C. Fontagné-Faucher, S. Bejar, and H. Chouayekh. 2013. Characterization of glucansucrase and dextran from Weissella sp. TN610 with potential as safe food additives. International Journal of Biological Macromolecules 52: 125–132.

Bradford, M.M. 1976. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry 72 (1): 248–254.

Carlson, V. W. and W. W. Carlson. 1955. Method of producing dextran material by bacteriological and enzymatic action. US. Patent No 2,709,150.

Colvin Harry, W.J., J.T. Attebery, and J.T. Ivy. 1961. Comparison of the anthrone reagent and a copper-reduction method for determining blood sugar in calves. Journal of Dairy Science 44 (11): 2081–2088.

Das Dipak, K., and S.K. Dutta. 1996. Purification, biochemical characterization and mode of action of an extracellular endo-dextranase from the culture filtrate of Penicillium lilacinum. The International Journal of Biochemistry & Cell Biology 28 (1): 107–113.

Eggleston, G., and A. Monge. 2005. Optimization of sugarcane factory application of commercial dextranases. Process Biochemistry 40 (5): 1881–1894.

Fukumoto, J., H. Tsuji, and D. Tsuru. 1971. Studies on mold dextranases I. Penicillium Luteum dextranase: Its production and some enzymatic properties. Journal of Biochemistry 69 (6): 1113–1121.

Galvez-Mariscal, A., and A. Lopez-Munguia. 1991. Production and characterization of a dextranase from an isolated Paecilomyces lilacinus strain. Applied Microbiology and Biotechnology 36 (3): 327–331.

Garcia, B., E. Margolles, H. Roca, D. Mateu, M. Raices, M.E. Gonzales, L. Herrera, and J. Delgado. 1996. Cloning and sequencing of a dextranase-encoding cDNA from Penicillium minioluteum. FEMS Microbiology Letters 143 (2–3): 175–183.

Hiraoka, N., J. Fukumoto, and D. Tsuru. 1972. Studies on mold dextranases III. Purification and some enzymatic properties of Aspergillus carneus dextranase. Journal of Biochemistry 71 (1): 57–64.

Huang, K., P.J. Zhang, B. Hu, and S.J. Yu. 2016. Monitoring the effect of the dextran molecular weight on sucrose crystallization by focused beam reflectance measurement (FBRM). Sugar Tech 18 (3): 325–332.

Imrie, F.K.E., and R.H. Tilbury. 1972. Polysaccharides in sugar cane and its products. Sugar Technology Review 1: 291–361.

Janson, J.C. 1987. On the history of the development of Sephadex®. Chromatographia 23 (5): 361–365.

Jiao, Y.L., S.J. Wang, M.S. Lv, B.H. Jiao, W.J. Li, Y.W. Fang, and S. Liu. 2014. Characterization of a marine-derived dextranase and its application to the prevention of dental caries. Journal of Industrial Microbiology and Biotechnology 41 (1): 17–26.

Jiménez, E.R. 2009. Dextranase in sugar industry: A review. Sugar Tech 11 (2): 124–134.

Khalikova, E., P. Susi, N. Usanov, and T. Korpela. 2003. Purification and properties of extracellular dextranase from a Bacillus sp. Journal of Chromatography B 796 (2): 315–326.

Kim, Y.M., and D. Kim. 2009. Characterization of novel thermostable dextranase from Thermotoga lettingae TMO. Applied Microbiology and Biotechnology 85 (3): 581–587.

Kim, Y.M., Y. Kiso, T. Muraki, M.S. Kang, H. Nakai, W. Saburi, W. Lang, H.K. Kang, M. Okuyama, H. Mori, R. Suzuki, K. Funane, N. Suzuki, M. Momma, Z. Fujimoto, T. Oguma, M. Kobayashi, D. Kim, and A. Kimura. 2012. Novel dextranase catalyzing cycloisomaltooligosaccharide formation and identification of catalytic amino acids and their functions using chemical rescue approach. The Journal of Biological Chemistry 287 (24): 19927–19935.

Koenig, D., and D. Day. 1989. The purification and characterization of a dextranase from Lipomyces starkeyi. European Journal of Biochemistry 183 (1): 161–167.

Laemmli, U.K. 1970. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227: 680–685.

Larsen, B., B. Rask Poulsen, N.T. Eriksen, and J.J. Lønsmann Iversen. 2004. Homogeneous batch cultures of Aspergillus oryzae by elimination of wall growth in the variomixing bioreactor. Applied Microbiology and Biotechnology 64 (2): 192–198.

Larsson, A.M., R. Andersson, J. Ståhlberg, L. Kenne, and T.A. Jones. 2003. Dextranase from Penicillium minioluteum: Reaction course, crystal structure, and product complex. Structure 11 (9): 1111–1121.

Majumder, A., and A. Goyal. 2009. Rheological and gelling properties of a novel glucan from Leuconostoc dextranicum NRRL B-1146. Food Research International 42 (4): 525–528.

Milintawisamai, N., S. Niamsanit, C. Ngasan, U. Pliansinchai, and P. Weerathaworn. 2009. Dextran producing microorganisms from Mitr Phuveing Sugar Factory, Thailand. Sugar Tech 11 (2): 196–199.

Miller, G.L. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry 31 (3): 426–428.

Mizuno, M., A. Koide, A. Yamamura, H. Akeboshi, H. Yoshida, S. Kamitori, Y. Sakano, A. Nishikawa, and T. Tonozuka. 2008. Crystal structure of Aspergillus niger isopullulanase, a member of glycoside hydrolase family 49. Journal of Molecular Biology 376 (1): 210–220.

Nácher-Vázquez, Montserrat, Iñaki Iturria, Kenza Zarour, Maria Luz Mohedano, Rosa Aznar, Miguel Ángel Pardo, and Paloma López. 2017. Dextran production by Lactobacillus sakei MN1 coincides with reduced autoagglutination, biofilm formation and epithelial cell adhesion. Carbohydrate Polymers 168: 22–31.

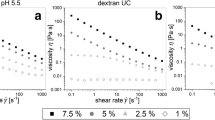

Netsopa, S., S. Niamsanit, D. Sakloetsakun, and N. Milintawisamai. 2018. Characterization and rheological behavior of Dextran from Weissella confusa R003. International Journal of Polymer Science 2018: 10.

Niamsanit, S., N. Milintawisamai, and P. Lanwonk. 2015. Feasibility study of dextranase from Aspergillus sp. X26 to degrade dextran in sugar cane juice. Conference Proceedings Nagoya Japan 1: 145–151.

Padmajanti, A., T. Tonozuka, and Y. Sakano. 2000. Deglycosylated isopullulanase retains enzymatic activity. Journal of Applied Glycoscience 47 (3–4): 287–292.

Park, T.S., J. Hyung-Jae, R. Jin-A, R. Young-Bae, P. Su-Jin, D. Do-Man, K. Young-Min, and W. Lee. 2012. Biochemical characterization of thermophilic dextranase from a thermophilic bacterium, Thermoanaerobacter pseudethanolicus. Journal of Microbiology and Biotechnology 22 (5): 637–641.

Pleszczyńska, M., J. Rogalski, J. Szczodrak, and J. Fiedurek. 1996. Purification and some properties of an extracellular dextranase from Penicillium notatum. Mycological Research 100 (6): 681–686.

Purushe, S., D. Prakash, N.N. Nawani, P. Dhakephalkar, and B. Kapadnis. 2012. Biocatalytic potential of an alkalophilic and thermophilic dextranase as a remedial measure for dextran removal during sugar manufacture. Bioresource Technology 115: 2–7.

Sarwat, F., S.A.U. Qader, A. Aman, and N. Ahmed. 2008. Production & characterization of a unique dextran from an indigenous Leuconostoc mesenteroides CMG713. International Journal of Biological Sciences 4 (6): 379–386.

Shimizu, E., T. Unno, M. Ohba, and G. Okada. 1998. Purification and characterization of an isomaltotriose-producing endo-dextranase from a Fusarium sp. Bioscience, Biotechnology, and Biochemistry 62 (1): 117–122.

Suzuki, N., Y.M. Kim, Z. Fujimoto, M. Momma, H.K. Kang, K. Funane, M. Okuyama, H. Mori, and A. Kimura. 2011. Crystallization and preliminary crystallographic analysis of dextranase from Streptococcus mutans. Acta Crystallographica, Section F: Structural Biology and Crystallization Communications 67 (12): 1542–1544.

Suzuki, N., Y.M. Kim, Z. Fujimoto, M. Momma, M. Okuyama, H. Mori, K. Funane, and A. Kimura. 2012. Structural elucidation of dextran degradation mechanism by Streptococcus mutans dextranase belonging to glycoside hydrolase family 66. The Journal of Biological Chemistry 287 (24): 19916–19926.

Virgen-Ortíz, J.J., V. Ibarra-Junquera, P. Escalante-Minakata, J. de Ornelas-Paz, J.A. Osuna-Castro, and A. González-Potes. 2015. Kinetics and thermodynamic of the purified dextranase from Chaetomium erraticum. Journal of Molecular Catalysis. B, Enzymatic 122: 80–86.

Wanda, S.Y., and R. Curtiss. 1994. Purification and characterization of Streptococcus sobrinus dextranase produced in recombinant Escherichia coli and sequence analysis of the dextranase gene. Journal of Bacteriology 176 (13): 3839–3850.

Wu, D.T., H.B. Zhang, L.J. Huang, and X.Q. Hu. 2011. Purification and characterization of extracellular dextranase from a novel producer, Hypocrea lixii F1002, and its use in oligodextran production. Process Biochemistry 46 (10): 1942–1950.

Wynter, C. 1997. Partial purification of a thermostable dextranase using Sephacryl S-300 adsorption. Letters in Applied Microbiology 25 (5): 321–324.

Zhang, Y.Q., R.H. Li, H.B. Zhang, M. Wu, and X.Q. Hu. 2016. Purification, characterization, and application of a thermostable dextranase from Talaromyces pinophilus. Journal of Industrial Microbiology and Biotechnology 44 (2): 317–327.

Acknowledgements

The authors would like to thank the Royal Golden Jubilee Ph.D. Program for financial support to the project and Mr. Netsopa. Supports from Department of Biochemistry, Faculty of Science, Khon Kaen University and the Department of Bioscience, School of Agriculture, Tokai University, Japan, are also recognized. We are thankful to Thailand and Protein and Proteomics Research Center for Commercial and Industrial Purposes (ProCCl) for supports. We are also grateful to Mitr Phol Sugarcane Research Center Co. Ltd, Thailand, for research participation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Netsopa, S., Niamsanit, S., Araki, T. et al. Purification and Characterization Including Dextran Hydrolysis of Dextranase from Aspergillus allahabadii X26. Sugar Tech 21, 329–340 (2019). https://doi.org/10.1007/s12355-018-0652-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-018-0652-9