Abstract

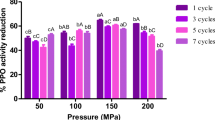

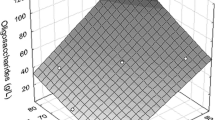

In this work, we investigated the influence of dextranase enzyme on the molecular weight parameters of remaining dextran and intrinsic viscosity after different enzymatic treatments at different steps during sugar manufacturing. A spectrophotometric method was used to determine the relative activity of dextranase and the result has been confirmed by measured reducing sugar using HPLC system. For comparison, the action patterns of concentrated and diluted enzymes were additionally included in the experiments. Addition of dextranase to juice were much more efficient and economical to reduce the Mw of remaining dextran than adding it to evaporator syrups. Addition of dextranase at juice pH 5.5 showed similar minimum Mw with the lowest intrinsic viscosity, observed at 55.0 °C, and activities decreased after 20°Brix. The highest dextran removal was observed at dextranase concentration at 100 ppm/juice which was resulted in 80.29 % removal dextran in the juice, Moreover, the higher the level of concentrated dextranase applied to the juice, the more the removal of dextran occurred. In addition, the longer the availability of the residence time in the factory, the lower dextran Mw has been observed. To reach a satisfactory level of dextran hydrolysis, it was necessary to correct the dose of dextranase enzyme according to the losses of activity caused by the high °Brix.

Similar content being viewed by others

References

Abdel-Rahman, E.A., Q. Smejkal, R. Schick, S. El-Syiad, and T. Kurz. 2008. Influence of dextran concentrations and molecular fractions on the rate of sucrose crystallization in pure sucrose solution. Journal of Food Engineering 84: 501–508.

Anon. 1996. Data sheet for Dextranex L-4000, Genencor.

Anon. 2002. Determination of dextranase using spectrophotometry. Novo-zymes EB-SM-0120-02/01.

Bashari, M., M. Nikoo, Z. Jin, Y. Bai, X. Xu, and N. Yang. 2012. Thermal and rheological properties of the supersaturated sucrose solution in the presence of different molecular weight fractions and concentrations of dextran. European Food Research and Technology 234(4): 639–648.

Bashari, M., A. Eibaid, J. Wang, Y. Tian, X. Xu, and Z. Jin. 2013. Influence of low ultrasound intensity on the degradation of dextran catalyzed by dextranase. Ultrasonics Sonochemistry 20: 155–161.

Brown, C.F., and P.A. Inkerman. 1992. Specific method for quantitative measurement of the total dextran content of raw sugar. Journal of Agriculture and Food Chemistry 40: 227–233.

Clarke, M.A., J. Bergeron, and F. Cole. 1987. A rapid dextran screening test. Sugar y Azucar 82(3): 23–24.

Cuddihy J.A., and D.F. Day. 1999. The process and financial impact of dextran on sugar factory. http://www.midlandresearchlabsinc.com. Accessed 13 May 2011.

Cuddihy J.A., J.S. Rauh, and M.E. Porro. 1998. Improving sugar recovery with sugar process chemicals. http://www.midlandresearchlabsinc.com. Accessed 13 May 2011.

DeStefano, R.P. 1988. Potential uses and associated benefits of dextranase enzyme in the raw sugar mill. Journal American Society of Sugar Cane Technologists 8: 99–104.

Eggleston, G., G. Côté, and C. Santee. 2011. New insights on the hard-to-boil massecuite phenomenon in raw sugar manufacture. Food Chemistry 126: 21–30.

Eggleston, G., and A. Monge. 2005. Optimization of sugarcane factory application of commercial dextranases. Process Biochemistry 40: 1881–1894.

Eggleston, G., A. Monge, B. Montes, and D. Stewart. 2009. Application of dextranases in sugarcane factory: Overcoming practical problems. Sugar Tech 11(2): 135–141.

Inkerman, P.A. 1980. An appraisal of the use of dextranase. Proceedings International Society of Sugar Cane Technologists 17: 2411–2427.

Inkerman P.A., and G.P. James. 1976. Dextranase II, practical application of the enzyme to sugar mills. Proceedings Queensland Society Sugar Cane Technologists, 43rd Conf, Watson Ferguson and Co, Brisbane, Queensland, Australia p 307–15.

Khalikova, E., P. Susi, and T. Korpela. 2005. Microbial dextran-hydrolyzing enzymes: Fundamentals and applications. Microbiology and Molecular Biology Reviews 69(2): 306–324.

Kim, D., and D.F. Day. 2004. Determination of dextran in raw sugar process streams. Food Science and Biotechnology 13: 248–252.

Kim, D., H.C. Seo, and D.F. Day. 1996. Dextran production by Leuconostoc mesenteroides in the presence of a dextranase producing yeast, Lipomyces starkeyi. Biotechnology Techniques 10: 227–232.

Kim, Y., E. Ko, H. Kang, and D. Kim. 2009. Construction, expression and characterization of fusion enzyme from Arthrobacter oxydans dextranase and Klebsiella pneumoniae amylase. Biotechnology Letters 31: 1019–1024.

Millson, S.H., and I.H. Evans. 2007. Multiple dextranases from the yeast Lipomyces starkeyi. Antonie van Leeuwenhoek 92: 399–404.

Morel du Boil, P.G., and S. Wienese. 2002. Enzymic reduction of dextran in process-laboratory evaluation of dextranases. Proceedings of South African Sugar Technologist Association 76: 435–443.

Nordmeier, E. 1993. Static and dynamic light-scattering solution behavior of pullulan and dextran in comparison. Journal of Physical Chemistry 97: 5110–5185.

Thitaram, S.N., C.H. Chung, D.F. Day, A. Hinton, J.S. Bailey, and G.R. Siragusa. 2005. Isomaltooligosaccharide increases cecal Bifidobacterium population in young broiler chickens 1. Poultry Science 84(7): 998–1003.

Acknowledgments

This study was financially supported by the Fundamental Research Funds for the Central Universities (No. JUSRP11225), Project of the State Key Laboratory of Food Science and Technology, Jiangnan University (No. SKLF-ZZB-201206), and the National Key Technology R&D Program for the 12th Five-Year Plan (Nos. 2012BAD37B01, 2012BAD37B02 and 2012BAD37B06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bashari, M., Tounkara, F., Abdelhai, M.H. et al. Impact of Dextranase on Sugar Manufacturing and its Kinetic on the Molecular Weights of Remaining Dextran. Sugar Tech 15, 84–93 (2013). https://doi.org/10.1007/s12355-012-0195-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-012-0195-4