Abstract

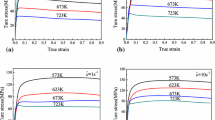

This research aims to characterize the effect of strain rate and temperature on flow behaviours under large plastic deformation for 5182-O aluminum alloy. Experiments are conducted with both dogbone and notched specimens at different strain rates and temperatures. All tests are analyzed by inverse engineering to identify the strain hardening behaviour at large plastic strains up to fracture. The experimental results show the highly coupling effect of strain rate and temperature. The two hardening laws of Swift-Voce model and p-model are calibrated by the finite element model update procedure, and the combination with the smallest error is selected as the input set of the artificial neural network (ANN) model. Then the dynamic hardening behaviours are modelled by the ANN to consider the highly coupled effect. The calibrated ANN model is further applied to ABAQUS/Explicit for numerical simulation under different loading conditions. Taking the finite element calculation time and prediction accuracy into consideration, the ANN model with single hidden layer optimized by particle swarm optimization algorithm is finally selected. The calibration results of the selected ANN model have the best consistency with an acceptable level of numerical computation time.

Similar content being viewed by others

References

Miller WS, Zhuang L, Bottema J, Wittebrood AJ, Smet PD, Haszler A, Vieregge A (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280:37–49. https://doi.org/10.1016/S0921-5093(99)00653-X

Mansouri LZ, Coër J, Thuillier S, Laurent H, Manach PY (2020) Investigation of Portevin-Le Châtelier effect during Erichsen test. Int J Mater Form 13:687–697. https://doi.org/10.1007/s12289-019-01511-5

Kabirian F, Khan AS, Pandey A (2014) Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: Experiment and constitutive modeling. Int J Plast 55:232–246. https://doi.org/10.1016/j.ijplas.2013.11.001

Jenab A, Taheri AK (2014) Experimental investigation of the hot deformation behavior of AA7075: Development and comparison of flow localization parameter and dynamic material model processing maps. Int J Mech Sci 78:97–105. https://doi.org/10.1016/j.ijmecsci.2013.11.003

Seth M, Vohnout VJ, Daehn GS (2005) Formability of steel sheet in high velocity impact. J Mater Process Technol 168(3):390–400. https://doi.org/10.1016/j. jmatprotec.2004.08.032

Khan AS, Baig M (2011) Anisotropic responses, constitutive modeling and the effects of strain-rate and temperature on the formability of an aluminum alloy. Int J Plast 27:522–538. https://doi.org/10.1016/j.ijplas.2010.08.001

Abedrabbo N, Pourboghrat F, Carsley J (2007) Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int J Plast 23:841–875. https://doi.org/10.1016/j.ijplas.2006.10.005

Ge YL, Xia Y, Zhou Q (2022) Influence of pre-straining and heating on strain-rate sensitivity of AA5182-O. Int J Impact Eng 161:104106. https://doi.org/10.1016/j.ijimpeng.2021.104106

Sadowski AJ, Rotter JM, Stafford PJ, Reinke T, Ummenhofer T (2017) On the gradient of the yield plateau in structural carbon steels. J Constr Steel Res 130:120–130. https://doi.org/10.1016/j.jcsr.2016.11.024

Reis LC, Oliveira MC, Santos AD, Fernandes JV (2016) On the determination of the work hardening curve using the bulge test. Int J Mech Sci 105:158–181. https://doi.org/10.1016/j.ijmecsci.2015.11.009

Traphöner H, Clausmeyer T, Tekkaya AE (2021) Methods for measuring large shear strains in in-plane torsion tests. J Mater Process Technol 287:116516. https://doi.org/10.1016/j.jmatprotec.2019.116516

Zhang C, Lou YS, Zhang SJ, Clausmeyer T, Tekkaya AE, Fu L, Chen Q, Zhang Q (2021) Large strain flow curve identification for sheet metals under complex stress states. Mech Mater 161:103997. https://doi.org/10.1016/j.mechmat.2021.103997

Knysh P, Korkolis YP (2017) Identification of the post-necking hardening response of rate- and temperature-dependent metals. Int J Solids Struct 115–116:149–160. https://doi.org/10.1016/j.ijsolstr.2017.03.012

Cordero RR, François M, Lira I, Vial-Edwards C (2005) Whole-field analysis of uniaxial tensile tests by Moiré interferometry. Opt Lasers Eng 43(9):919–936. https://doi.org/10.1016/j.optlaseng.2004.10.002

Petit J, Montay G, François M (2014) Strain rate measurements by speckle interferometry for necking investigation in stainless steel. Int J Solids Struct 51(2):540–550. https://doi.org/10.1016/j.ijsolstr.2013.10.029

Avril S, Bonnet M, Bretelle AS, Grédiac M, Hild F, Ienny P, Latourte F, Lemosse D, Pagano S, Pagnacco E, Pierron F (2008) Overview of Identification Methods of Mechanical Parameters Based on Full-field Measurements. Exp Mech 48(4):381. https://doi.org/10.1007/s11340-008-9148-y

Yang WK, Wang LY, Song ZM, Luo XM, Zhang GP (2021) Tensile Plasticity of Miniature Specimens for a Low Alloy Steel Investigated by Digital Image Correlation Technique. steel res int 92(7):2000685. https://doi.org/10.1002/srin.202000685

Peirs J, Verleysen P, Paepegem WV, Degrieck J (2011) Determining the stress–strain behaviour at large strains from high strain rate tensile and shear experiments. Int J Impact Eng 38(5):406–415. https://doi.org/10.1016/j.ijimpeng.2011.01.004

Lou YS, Zhang SJ, Yoon JW (2020) Strength modeling of sheet metals from shear to plane strain tension. Int J Plast 134:102813. https://doi.org/10.1016/j.ijplas.2020.102813

Denys K, Coppieters S, Debruyne D (2018) On the identification of a high-resolution multi-linear post-necking strain hardening model. Comptes Rendus Mécanique 346(8):712–723. https://doi.org/10.1016/j.crme.2018.06.002

Zhang H, Coppieters S, Jiménez-Peña C, Debruyne D (2019) Inverse identification of the post-necking work hardening behaviour of thick HSS through full-field strain measurements during diffuse necking. Mech Mater 129:361–374. https://doi.org/10.1016/j.mechmat.2018.12.014

Jenab A, Sarraf IS, Green DE, Rahmaan T, Worswick MJ (2016) The Use of genetic algorithm and neural network to predict rate-dependent tensile flow behaviour of AA5182-O sheets. Mater Des 94:262–273. https://doi.org/10.1016/j.matdes.2016.01.038

Li XY, Roth CC, Mohr D (2019) Machine-learning based temperature- and rate-dependent plasticity model: Application to analysis of fracture experiments on DP steel. Int J Plast 118:320–344. https://doi.org/10.1016/j.ijplas.2019.02.012

Jordan B, Gorji MB, Mohr D (2020) Neural network model describing the temperature- and rate-dependent stress-strain response of polypropylene. Int J Plast 135:102811. https://doi.org/10.1016/j.ijplas.2020.102811

Lou YS, Huh H (2013) Prediction of ductile fracture for advanced high strength steel with a new criterion: Experiments and simulation. J Mater Process Technol 213(8):1284–1302. https://doi.org/10.1016/j.jmatprotec.2013.03.001

Mogucheva A, Yuzbekova D, Kaibyshev R, Lebedkina T, Lebyodkin M (2016) Effect of Grain Refinement on Jerky Flow in an Al-Mg-Sc Alloy. Metall Mater Trans A 47(5):2093–2106. https://doi.org/10.1007/s11661-016-3381-2

Zhemchuzhnikova D, Lebyodkin M, Yuzbekova D, Lebedkina T, Mogucheva A, Kaibyshev R (2018) Interrelation between the Portevin Le-Chatelier effect and necking in AlMg alloys. Int J Plast 110:95–109. https://doi.org/10.1016/j.ijplas.2018.06.012

Rodriguez P, Srinivasan V (1995) Serrated Plastic Flow Revisited. Solid State Phenom. 42–43: 257–266. https://doi.org/10.4028/www.scientific.net/SSP.42-43.257

Mirone G, Barbagallo R (2021) How sensitivity of metals to strain, strain rate and temperature affects necking onset and hardening in dynamic tests. Int J Mech Sci 195:106249. https://doi.org/10.1016/j.ijmecsci.2020.106249

Khan AS, Pandey A, Gnäupel-Herold T, Mishra RK (2011) Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int J Plast 27(5):688–706. https://doi.org/10.1016/j.ijplas.2010.08.009

Pham QT, Lee BH, Park KC, Kim YS (2018) Influence of the post-necking prediction of hardening law on the theoretical forming limit curve of aluminium sheets. Int J Mech Sci 140:521–536. https://doi.org/10.1016/j.ijmecsci.2018.02.040

Mohr D, Marcadet SJ (2015) Micromechanically-motivated phenomenological Hosford–Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int J Solids Struct 67–68:40–55. https://doi.org/10.1016/j.ijsolstr.2015.02.024

Sung JH, Kim JH, Wagoner RH (2010) A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int J Plast 26:1746–1771. https://doi.org/10.1016/j.ijplas.2010.02.005

Roth CC, Mohr D (2014) Effect of strain rate on ductile fracture initiation in advanced high strength steel sheets: Experiments and modeling. Int J Plast 56:19–44. https://doi.org/10.1016/j.ijplas.2014.01.003

Pham QT, Kim YS (2017) Identification of the plastic deformation characteristics of AL5052-O sheet based on the non-associated flow rule. Met Mater Int 23(2):254–263. https://doi.org/10.1007/s12540-017-6378-5

Coppieters S, Kuwabara T (2014) Identification of post-Necking hardening phenomena in ductile sheet metal. Exp Mech 54:1355–1371. https://doi.org/10.1007/s11340-014-9900-4

Shang HC, Wu PF, Lou YS, Wang JZ, Chen Q (2022) Machine learning-based modeling of the coupling effect of strain rate and temperature on strain hardening for 5182-O aluminum alloy. J Mater Process Technol 302:117501. https://doi.org/10.1016/j.jmatprotec.2022.117501

Ren C, An N, Wang JZ, Li L, Hu B, Shang D (2014) Optimal parameters selection for BP neural network based on particle swarm optimization: A case study of wind speed forecasting. Knowl Based Syst 56:226–239. https://doi.org/10.1016/j.knosys.2013.11.015

Acknowledgements

The authors also acknowledge the financial supports by the National Natural Science Foundation of China (Grant No. 52075423), the State Key Laboratory of Mechanical System and Vibration (Grant No. MSV202009), and the State Key Laboratory of High Performance Complex Manufacturing (Grant No. Kfkt2019-02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix A. Calibrated parameters of two hardening models

Appendix A. Calibrated parameters of two hardening models

Swift-Voce model | |||||||

|---|---|---|---|---|---|---|---|

K | ɛ0 | n | A | B | C | ||

300 K | 0.001/s | 329.22 | 0.0058 | 0.3736 | 536.80 | 207.16 | 9.5117 |

0.01/s | 321.38 | 0.0044 | 0.3639 | 508.96 | 189.88 | 11.349 | |

0.1/s | 296.09 | 0.0093 | 0.3839 | 496.86 | 193.09 | 13.310 | |

1/s | 357.43 | 0.0073 | 0.3300 | 449.75 | 171.46 | 12.587 | |

373 K | 0.001/s | 464.62 | 0.0069 | 0.2738 | 426.85 | 146.09 | 6.5699 |

0.01/s | 410.64 | 0.0047 | 0.3470 | 468.72 | 201.30 | 9.5559 | |

0.1/s | 245.75 | 0.0296 | 0.2927 | 502.22 | 192.86 | 11.565 | |

1/s | 604.78 | 0.0082 | 0.2680 | 227.76 | 109.34 | 29.467 | |

423 K | 0.001/s | 529.02 | 0.0066 | 0.4110 | 276.39 | 194.67 | 13.007 |

0.01/s | 324.22 | 0.0035 | 0.3531 | 458.41 | 241.24 | 7.5186 | |

0.1/s | 335.81 | 0.0073 | 0.3844 | 448.96 | 203.29 | 12.791 | |

1/s | 303.95 | 0.0085 | 0.3884 | 442.91 | 199.66 | 15.045 | |

473 K | 0.001/s | 422.44 | 0.0053 | 0.4000 | 218.93 | 175.14 | 18.458 |

0.01/s | 416.67 | 0.0091 | 0.4483 | 295.66 | 214.03 | 11.151 | |

0.1/s | 367.37 | 0.0061 | 0.3915 | 362.32 | 207.88 | 17.840 | |

1/s | 327.20 | 0.0083 | 0.3414 | 378.94 | 215.46 | 21.157 | |

523 K | 0.001/s | 297.24 | 0.0005 | 0.2436 | 122.28 | 158.73 | 16.447 |

0.01/s | 419.12 | 0.0041 | 0.3424 | 195.34 | 155.24 | 6.7202 | |

0.1/s | 390.67 | 0.0046 | 0.3632 | 239.01 | 187.16 | 28.470 | |

1/s | 308.31 | 0.0061 | 0.3370 | 319.59 | 205.61 | 16.095 | |

573 K | 0.001/s | 246.33 | 0.00002 | 0.2587 | 100.12 | 144.23 | 41.066 |

0.01/s | 425.91 | 0.0101 | 0.3829 | 84.721 | 145.56 | 17.087 | |

0.1/s | 390.94 | 0.0057 | 0.3844 | 195.18 | 152.38 | 4.7541 | |

1/s | 359.41 | 0.0011 | 0.2874 | 219.27 | 125.04 | 12.501 | |

p-model | |||||||

|---|---|---|---|---|---|---|---|

K | ɛ0 | n | ɛmax | Q | p | ||

300 K | 0.001/s | 561.40 | 0.0083 | 0.3245 | 0.11 | 116.67 | 6.6008 |

0.01/s | 572.40 | 0.0061 | 0.3329 | 0.11 | 91.898 | 8.7197 | |

0.1/s | 560.32 | 0.0080 | 0.3312 | 0.11 | 76.900 | 10.077 | |

1/s | 543.01 | 0.0065 | 0.3182 | 0.19 | 31.664 | 16.544 | |

373 K | 0.001/s | 514.87 | 0.0060 | 0.2926 | 0.18 | 119.04 | 4.1582 |

0.01/s | 532.44 | 0.0070 | 0.2914 | 0.24 | 150.60 | 2.7750 | |

0.1/s | 451.93 | 0.0007 | 0.2295 | 0.18 | 135.57 | 2.8582 | |

1/s | 428.65 | 0.000004 | 0.2013 | 0.20 | 42.859 | 7.2813 | |

423 K | 0.001/s | 388.73 | 0.0051 | 0.2256 | 0.28 | 351.75 | 0.6491 |

0.01/s | 416.17 | 0.0027 | 0.2188 | 0.13 | 130.86 | 3.3693 | |

0.1/s | 474.89 | 0.0042 | 0.2702 | 0.15 | 63.979 | 7.8474 | |

1/s | 444.06 | 0.0032 | 0.2463 | 0.14 | 56.294 | 8.4066 | |

473 K | 0.001/s | 285.11 | 0.0011 | 0.1793 | 0.12 | 143.71 | 1.9774 |

0.01/s | 308.06 | 0.0010 | 0.1643 | 0.10 | 182.83 | 1.8083 | |

0.1/s | 324.20 | 0.0008 | 0.1449 | 0.08 | 198.70 | 2.0204 | |

1/s | 325.85 | 0.0008 | 0.1313 | 0.07 | 183.88 | 2.1703 | |

523 K | 0.001/s | 206.12 | 0.0201 | 0.1557 | 0.09 | 118.85 | 1.7351 |

0.01/s | 225.23 | 0.0026 | 0.1094 | 0.05 | 180.26 | 1.8348 | |

0.1/s | 277.31 | 0.0016 | 0.1412 | 0.10 | 125.80 | 2.1943 | |

1/s | 350.96 | 0.0087 | 0.2119 | 0.04 | 90.690 | 8.8691 | |

573 K | 0.001/s | 129.21 | 0.0197 | 0.1005 | 0.09 | 72.214 | 1.2626 |

0.01/s | 198.88 | 0.0109 | 0.1493 | 0.10 | 164.01 | 1.1483 | |

0.1/s | 247.26 | 0.0059 | 0.1776 | 0.09 | 177.84 | 1.6027 | |

1/s | 260.77 | 0.0003 | 0.1562 | 0.09 | 151.42 | 1.8904 | |

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shang, H., Zhang, C., Wang, S. et al. Large strain flow curve characterization considering strain rate and thermal effect for 5182-O aluminum alloy. Int J Mater Form 16, 1 (2023). https://doi.org/10.1007/s12289-022-01721-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-022-01721-4