Abstract

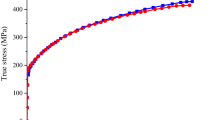

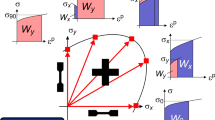

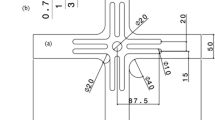

Biaxial tensile test has been drawing attention as an effective approach to characterize sheet metal formability. In this research, a new cruciform specimen is provided to determine the forming limits at fracture from shear to plane strain. AA6061-O sheet with a thickness of 2 mm is employed as a target material. Firstly, three different contours (Type I—rectangular contour, Type II—circular contour and Type III—elliptical contour) of the specimen thickness reduction zone are proposed, and the effect of the contour on strain path, stress state and strain distribution is numerically investigated. It is found that the cruciform specimen with the elliptical notch contour has high potential to be used for determining the fracture strains. Then, the design is experimentally verified under shear, shear-tension and plane strain conditions. Based on the analyses of the experimental strain distributions, strain paths and initial fracture locations, the performance of the new cruciform specimen is illustrated and discussed. Finally, the finite element model of the new cruciform specimen coupled with the calibrated DF2014 damage criterion is employed to predict the FLCF of AA6061-O.

Similar content being viewed by others

References

Burd JTJ, Moore EA, Ezzat H, Kirchain R, Roth R (2021) Improvements in electric vehicle battery technology influence vehicle lightweighting and material substitution decisions. Appl Energ 283:116269. https://doi.org/10.1016/j.apenergy.2020.116269

Myhr OR, Børvik T, Marioara CD, Wenner S, Hopperstad OS (2020) Nanoscale modelling of combined isotropic and kinematic hardening of 6000 series aluminium alloys. Mech Mater 151:103603. https://doi.org/10.1016/j.mechmat.2020.103603

Cui J, Qi L, Jiang H, Li G, Zhang X (2018) Numerical and experimental investigations in electromagnetic riveting with different rivet dies. Int J Mater Form 11:839–853. https://doi.org/10.1007/s12289-017-1394-z

Keeler SP, Backhofen WA (1964) Plastic instability and fracture in sheets stretched over rigid punches. ASM Trans Quart 56:25–48

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. SAE Technical Paper 77:380–387. https://doi.org/10.4271/680093

Silva MB, Nielsen PS, Bay N, Martins PAF (2011) Failure mechanisms in single-point incremental forming of metals. Int J Adv Manuf Technol 56:893–903. https://doi.org/10.1007/s00170-011-3254-1

Paul SK (2021) Controlling factors of forming limit curve: A review. Adv Ind Manuf Eng 2:100033. https://doi.org/10.1016/j.aime.2021.100033

Lou Y, Huh H (2013) Extension of a shear-controlled ductile fracture model considering the stress triaxiality and the Lode parameter. Int J Solids Struct 50:447–455. https://doi.org/10.1016/j.ijsolstr.2012.10.007

Yue Z, Min X, Tuo Z, Soyarslan C, Zhuang X, Badreddine H, Saanouni K, Gao J (2021) Broad stress triaxiality ratio band fracture experiments in DP900 metal sheets and corresponding predictive capability of advanced phenomenological and micromechanical fully coupled damage models. Mater Sci Eng A 811:140978. https://doi.org/10.1016/j.msea.2021.140978

Mu L, Jia Z, Ma Z, Shen F, Sun Y, Zang Y (2020) A theoretical prediction framework for the construction of a fracture forming limit curve accounting for fracture pattern transition. Int J Plasticity 129:102706. https://doi.org/10.1016/j.ijplas.2020.102706

Chu X, Wang Z, Chen C, Lin S, Leotoing L (2020) Experimental investigation of punch curvature influence in Nakazima test and numerical FLD prediction of AA5086. Ferroelectrics 565(1):12–25. https://doi.org/10.1080/00150193.2020.1761714

Chu X, Leotoing L, Guines D, Ragneau E (2014) Temperature and strain rate influence on AA5086 Forming Limit Curves: experimental results and discussion on the validity of the MK model. Int J Mech Sci 78:27–34. https://doi.org/10.1016/j.ijmecsci.2013.11.002

Volk W, Gaber C (2017) Investigation and compensation of biaxial pre-strain during the standard Nakajima- and Marciniak-test using generalized forming limit concept. Procedia Eng 207:568–573. https://doi.org/10.1016/j.proeng.2017.10.1022

Min J, Stoughton TB, Carsley JE, Lin J (2016) Compensation for process-dependent effects in the determination of localized necking limits. Int J Mech Sci 117:115–134. https://doi.org/10.1016/j.ijmecsci.2016.08.008

Farahnak P, Urbanek M, Konopik P, Dzugan J (2020) Influence of thickness reduction on forming limits of mild steel DC01. Int J Mater Form 13:371–381. https://doi.org/10.1007/s12289-019-01513-3

Leotoing L, Guines D (2015) Investigations of the effect of strain path changes on forming limit curves using an in-plane biaxial tensile test. Int J Mech Sci 99:21–28. https://doi.org/10.1016/j.ijmecsci.2015.05.007

Kuwabara T, Ikeda S, Kuroda K (1998) Measurement and analysis of differential work hardening in cold-rolled steel sheet under biaxial tension. J Mater Process Technol 80–81:517–523. https://doi.org/10.1016/S0924-0136(98)00155-1

Hanabusa Y, Takizawa H, Kuwabara T (2013) Numerical verification of a biaxial tensile test method using a cruciform specimen. J Mater Process Technol 213(6):961–970. https://doi.org/10.1016/j.jmatprotec.2012.12.007

Kuwabara T, Bael AV, Iizuka E (2002) Measurement and analysis of yield locus and work hardening characteristics of steel sheets wtih different r-values. Acta Mater 50(14):3717–3729. https://doi.org/10.1016/S1359-6454(02)00184-2

Teaca M, Charpentier I, Martiny M, Ferron G (2010) Identification of sheet metal plastic anisotropy using heterogeneous biaxial tensile tests. Int J Mech Sci 52(4):572–580. https://doi.org/10.1016/j.ijmecsci.2009.12.003

Martins JMP, Andrade-Campos A, Thuillier S (2019) Calibration of anisotropic plasticity models using a biaxial test and the virtual fields method. Int J Solids Struct 172–173:21–37. https://doi.org/10.1016/j.ijsolstr.2019.05.019

Zhang S, Leotoing L, Guines D, Thuillier S (2014) Calibration of anisotropic yield criterion with conventional tests or biaxial test. Int J Mech Sci 85:142–151. https://doi.org/10.1016/j.ijmecsci.2014.05.020

Liu W, Guines D, Leotoing L, Ragneau E (2015) Identification of sheet metal hardening for large strains with an in-plane biaxial tensile test and a dedicated cross specimen. Int J Mech Sci 101–102:387–398. https://doi.org/10.1016/j.ijmecsci.2015.08.022

Liu W, Guines D, Leotoing L, Ragneau E (2016) Identification of strain rate-dependent mechanical behaviour of DP600 under in-plane biaxial loadings. Mat Sci Eng A 676:366–376. https://doi.org/10.1016/j.msea.2016.08.125

Schlosser F, Signorelli J, Leonard M, Roatta A, Milesi M, Bozzolo N (2019) Influence of the strain path changes on the formability of a zinc sheet. J Mater Process Technol 271:101–110. https://doi.org/10.1016/j.jmatprotec.2019.03.026

Zhang R, Shao Z, Shi Z, Dean TA, Lin J (2021) Effect of cruciform specimen design on strain paths and fracture location in equi-biaxial tension. J Mater Process Technol 289:116932. https://doi.org/10.1016/j.jmatprotec.2020.116932

Zidane I, Guines D, Leotoing L, Ragneau E (2010) Development of an in-plane biaxial test for forming limit curve (FLC) characterization of metallic sheets. Meas Sci Technol 21(5):055701. https://doi.org/10.1088/0957-0233/21/5/055701

Leotoing L, Guines D, Zidane I, Ragneau E (2013) Cruciform shape benefits for experimental and numerical evaluation of sheet metal formability. J Mater Process Technol 213(6):856–863. https://doi.org/10.1016/j.jmatprotec.2012.12.013

Song X, Leotoing L, Guines D, Ragneau E (2017) Characterization of forming limits at fracture with an optimized cruciform specimen: Application to DP600 steel sheets. Int J Mech Sci 126:35–43. https://doi.org/10.1016/j.ijmecsci.2017.03.023

Xiao R, Li XX, Liang LH, Song Q, Liu KN (2017) Forming limit in thermal cruciform biaxial tensile testing of titanium alloy. J Mater Process Technol 240:354–361. https://doi.org/10.1016/j.jmatprotec.2016.10.016

Wang ZJ, Zheng LH, Wang Z (2020) Characterization of forming limits at fracture for aluminum alloy 6K21-T4 sheets in non-linear strain paths using a biaxial tension/shear loading test. Int J Mech Sci 184:105672. https://doi.org/10.1016/j.ijmecsci.2020.105672

Driemeier L, Brünig M, Micheli G, Alves M (2010) Experiments on stress-triaxiality dependence of material behavior of aluminum alloys. Mech Mater 42:207–217. https://doi.org/10.1016/j.mechmat.2009.11.012

Zheng LH, Wang ZJ, Wang Z (2019) Characterizing forming limits at fracture for aluminum 6K21-T4 sheets using an improved biaxial tension/shear loading test. Int J Mech Sci 159:487-501. 10.1016/j.ijmecsci.2019.05.033

Brünig M, Brenner D, Gerke S (2015) Stress state dependence of ductile damage and fracture behavior: Experiments and numerical simulations. Eng Fract Mech 141:152–169. https://doi.org/10.1016/j.engfracmech.2015.05.022

Brünig M, Gerke S, Schmidt M (2018) Damage and failure at negative stress triaxialities: Experiments, modeling and numerical simulations. Int J Plasticity 102:70–82. https://doi.org/10.1016/j.ijplas.2017.12.003

Gerke S, Adulyasak P, Brünig M (2017) New biaxially loaded specimens for the analysis of damage and fracture in sheet metals. Int J Solids Struct 110–111:209–218. https://doi.org/10.1016/j.ijsolstr.2017.01.027

Brünig M, Gerke S, Zistl M (2019) Experiments and numerical simulations with the H-specimen on damage and fracture of ductile metals under non-proportional loading paths. Eng Fract Mech 217:106531. https://doi.org/10.1016/j.engfracmech.2019.106531

Gerke S, Zistl M, Bhardwaj A, Brünig M (2019) Experiments with the X0-specimen on the effect of non-proportional loading paths on damage and fracture mechanisms in aluminum alloys. Int J Solids Struct 163:157–169. https://doi.org/10.1016/j.ijsolstr.2019.01.007

Lou Y, Yoon JW, Huh H (2014) Modeling of shear ductile fracture considering a changeable cut-off value for stress triaxiality. Int J Plasticity 54:56–80. https://doi.org/10.1016/j.ijplas.2013.08.006

Lou Y, Chen L, Clausmeyer T, Tekkaya AE, Yoon JW (2017) Modeling of ductile fracture from shear to balanced biaxial tension for sheet metals. Int J Solids Struct 112:169–184. https://doi.org/10.1016/j.ijsolstr.2016.11.034

Acknowledgements

Z. WANG acknowledges the China Scholarship Council (CSC) for his Ph.D. financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Z., Guines, D., Chu, X. et al. Characterization of forming limits at fracture from shear to plane strain with a dedicated cruciform specimen. Int J Mater Form 15, 7 (2022). https://doi.org/10.1007/s12289-022-01658-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-022-01658-8