Abstract

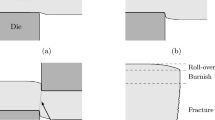

In this work, the effects of various process input parameters in the sheared edge characteristics are studied during shear-cutting of DP980 sheet material. A virtual experimental approach, based on finite element (FE) modeling of the trimming process, is used to investigate the shearing mechanism precisely. In this context, the Hosford–Coulomb (HC) fracture model is used to predict the fracture initiation, and a hybrid experimental-numerical technique is adopted to calibrate HC parameters. Furthermore, the calibrated HC model is incorporated into FE simulation of the shear-cutting process. Experimental sheet trimming setup is also developed to conduct the experiments, and subsequently validate the developed FE models. It is found that the sheared edge quality and trimming load are varied by the process parameters including trimming angle, trimming clearance and punch radius. Therefore, regression models are proposed to understand the effect on the sheared edge profile and trimming load while varying the input parameters simultaneously. Subsequently, these regression models are represented in the 3D space as a function of the input parameters to visualize the tendency of variations of process parameters on outputs over the operating range. The mathematical models are useful to predict and subsequently improve sheared edge quality by varying the process parameters. Furthermore, a comparison between the open-cut and close-cut processes has also been studied. Two different crack propagation mechanisms are observed due to difference in the boundary conditions regarding rotation of the scrap. For this reason, a strong variation in the stress triaxiality evolution is observed between two processes.

Similar content being viewed by others

References

Golovashchenko SF, Wang N, Le Q (2019) Trimming and sheared edge stretchability of automotive 6xxx aluminum alloys. J Mater Process Technol 264:64–75. https://doi.org/10.1016/j.jmatprotec.2018.09.001

Hu XH, Sun X, Golovashchenko SF (2016) An integrated finite element-based simulation framework: from hole piercing to hole expansion. Finite Elem Anal Des 109:1–13. https://doi.org/10.1016/j.finel.2015.09.005

Golovashchenko S, Zhou W, Nasheralahkami S, Wang N (2017) Trimming and sheared edge Stretchability of light weight sheet metal blanks. Procedia Eng 207:1552–1557. https://doi.org/10.1016/j.proeng.2017.10.1077

Feistle M, Koslow I, Krinninger M et al (2017) Reduction of Burr formation for conventional shear cutting of boron-alloyed sheets through focused heat treatment. Procedia CIRP 63:493–498. https://doi.org/10.1016/j.procir.2017.03.161

He J, Li S, Dong L (2020) Experiments and FE simulation of edge cracking considering prehardening after blanking process. Int J Mater Form 13:547–560. https://doi.org/10.1007/s12289-019-01491-6

Habibi N, Beier T, Richter H, et al (2019) The effects of shear affected zone on edge crack sensitivity in dual-phase steels. In: IOP Conference Series: Materials Science and Engineering. 651: 12073.

Krinninger M, Steinlehner F, Opritescu D et al (2017) On the influence of different parameters on the characteristic cutting surface when shear cutting aluminum. Procedia CIRP 63:230–235. https://doi.org/10.1016/j.procir.2017.03.156

Mori K ichiro, Abe Y, Suzui Y (2010) Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J Mater Process Technol 210:653–659. https://doi.org/10.1016/j.jmatprotec.2009.11.014

Dalloz A, Besson J, Gourgues-Lorenzon AF et al (2009) Effect of shear cutting on ductility of a dual phase steel. Eng Fract Mech 76:1411–1424. https://doi.org/10.1016/j.engfracmech.2008.10.009

Li M (2000) Experimental investigation on cut surface and burr in trimming aluminum autobody sheet. Int J Mech Sci 42:889–906. https://doi.org/10.1016/S0020-7403(99)00033-8

Atkins AG (1990) On the mechanics of guillotining ductile metals. J Mater Process Technol 24:245–257

Xu J, Guo B, Wang C, Shan D (2012) Blanking clearance and grain size effects on micro deformation behavior and fracture in micro-blanking of brass foil. Int J Mach Tools Manuf 60:27–34. https://doi.org/10.1016/j.ijmachtools.2012.04.001

Choi HS, Kim BM, Ko DC (2014) Effect of clearance and inclined angle on sheared edge and tool failure in trimming of DP980 sheet. J Mech Sci Technol 28:2319–2328. https://doi.org/10.1007/s12206-014-0522-7

Chumrum P, Koga N, Premanond V (2015) Experimental investigation of energy and punch wear in piercing of advanced high-strength steel sheet. Int J Adv Manuf Technol 79:1035–1042

So H, Faßmann D, Hoffmann H et al (2012) An investigation of the blanking process of the quenchable boron alloyed steel 22MnB5 before and after hot stamping process. J Mater Process Technol 212:437–449. https://doi.org/10.1016/j.jmatprotec.2011.10.006

Mori K, Maeno T, Fuzisaka S (2012) Punching of ultra-high strength steel sheets using local resistance heating of shearing zone. J Mater Process Technol 212:534–540. https://doi.org/10.1016/j.jmatprotec.2011.10.021

Basak S, Prasad KS, Sidpara AM, Panda SK (2019) Single point incremental forming of AA6061 thin sheet: calibration of ductile fracture models incorporating anisotropy and post forming analyses. Int J Mater Form 12:623–642

Alaswad A, Olabi AG, Benyounis KY (2011) Integration of finite element analysis and design of experiments to analyse the geometrical factors in bi-layered tube hydroforming. Mater\& Des 32:838–850

Schenek A, Liewald M (2021) Punching with a slant angle-cutting surface quality. Esaform 2021. https://doi.org/10.25518/esaform21.455

Basak S, Panda SK (2018) Implementation of Yld96 anisotropy plasticity theory for estimation of polar effective plastic strain based failure limit of pre-strained thin steels. Thin-Walled Struct 126:26–37. https://doi.org/10.1016/j.tws.2017.04.015

Taupin E, Breitling J, Wu WT, Altan T (1996) Material fracture and burr formation in blanking results of FEM simulations and comparison with experiments. J Mater Process Technol 59:68–78. https://doi.org/10.1016/0924-0136(96)02288-1

Wai Myint P, Hagihara S, Tanaka T et al (2017) Determination of the values of critical ductile fracture criteria to predict fracture initiation in punching processes. J Manuf Mater Process 1:12. https://doi.org/10.3390/jmmp1020012

Marouani H, Aguir H (2012) Identification of material parameters of the Gurson--Tvergaard--Needleman damage law by combined experimental, numerical sheet metal blanking techniques and artificial neural networks approach. Int J Mater Form 5:147–155

Han X, Yang K, Ding Y et al (2016) Numerical and experimental investigations on mechanical trimming process for hot stamped ultra-high strength parts. J Mater Process Technol 234:158–168. https://doi.org/10.1016/j.jmatprotec.2016.03.025

Wang C, Chen J, Xia C et al (2014) A new method to calculate threshold values of ductile fracture criteria for advanced high-strength sheet blanking. J Mater Eng Perform 23:1296–1306. https://doi.org/10.1007/s11665-013-0861-z

Mohr D, Marcadet SJ (2015) Micromechanically-motivated phenomenological Hosford – coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int J Solids Struct 68:40–55. https://doi.org/10.1016/j.ijsolstr.2015.02.024

Hu Q, Li X, Han X, Chen J (2017) A new shear and tension based ductile fracture criterion: modeling and validation. Eur J Mech 66:370–386

Lou Y, Huh H (2013) Prediction of ductile fracture for advanced high strength steel with a new criterion: experiments and simulation. J Mater Process Technol 213:1284–1302

Caro LP, Schill M, Haller K et al (2020) Damage and fracture during sheet-metal forming of alloy 718. Int J Mater Form 13:15–28

Basak S, Panda SK (2019) Necking and fracture limit analyses of different pre-strained sheet materials in polar effective plastic strain locus using Yld2000-2d yield model. J Mater Process Tech 267:289–307. https://doi.org/10.1016/j.jmatprotec.2018.10.004

Kim C, Min KM, Choi H, Kim HJ, Lee MG (2021) Development of analytical strength estimator for self-piercing rivet joints through observation of finite element simulations. Int J Mech Sci 202–203:106499. https://doi.org/10.1016/j.ijmecsci.2021.106499

Samadian P, ten Kortenaar L, Omer K et al (2020) Fracture characterization of tailored Usibor®1500-AS and damage modelling based on a coupled-micromechanical-phenomenological strategy. Eng Fract Mech 223:106785

Basak S, Panda SK (2019) Failure strains of anisotropic thin sheet metals : experimental evaluation and theoretical prediction. Int J Mech Sci 151:356–374. https://doi.org/10.1016/j.ijmecsci.2018.10.065

Dunand M, Mohr D (2010) Hybrid experimental-numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 47:1130–1143. https://doi.org/10.1016/j.ijsolstr.2009.12.011

Luo M, Dunand M, Mohr D (2012) Experiments and modeling of anisotropic aluminum extrusions under multi-axial loading - part II: ductile fracture. Int J Plast 32–33:36–58. https://doi.org/10.1016/j.ijplas.2011.11.001

Roth CC, Mohr D (2016) Ductile fracture experiments with locally proportional loading histories. Int J Plast 79:328–354. https://doi.org/10.1016/j.ijplas.2015.08.004

Gu G, Mohr D (2015) Anisotropic Hosford--Coulomb fracture initiation model: Theory and application. Eng Fract Mech 147:480–497

Marcadet SJ, Mohr D (2015) Effect of compression-tension loading reversal on the strain to fracture of dual phase steel sheets. Int J Plast 72:21–43. https://doi.org/10.1016/j.ijplas.2015.05.002

Pack K, Mohr D (2017) Combined necking & fracture model to predict ductile failure with shell finite elements. Eng Fract Mech 182:32–51. https://doi.org/10.1016/j.engfracmech.2017.06.025

Lou Y, Chen L, Clausmeyer T et al (2017) Modeling of ductile fracture from shear to balanced biaxial tension for sheet metals. Int J Solids Struct 112:169–184. https://doi.org/10.1016/j.ijsolstr.2016.11.034

Neukamm F, Feucht M, Haufe A (2008) Consistent damage modelling in the process chain of forming to crashworthiness simulations. LS-DYNA Anwenderforum 30:11–20

Andrade FXC, Feucht M, Haufe A, Neukamm F (2016) An incremental stress state dependent damage model for ductile failure prediction. Int J Fract 200:127–150. https://doi.org/10.1007/s10704-016-0081-2

Basak S, Panda SK, Lee MG (2020) Formability and fracture in deep drawing sheet metals: extended studies for pre-strained anisotropic thin sheets. Int J Mech Sci 170:105346. https://doi.org/10.1016/j.ijmecsci.2019.105346

Mattiasson K, Jergéus J, Dubois P (2014) On the prediction of failure in metal sheets with special reference to strain path dependence. Int J Mech Sci 88:175–191. https://doi.org/10.1016/j.ijmecsci.2014.08.006

Hallquist JO, others (2007) LS-DYNA keyword user’s manual. Livermore Softw Technol Corp 970:299–800

Kiran R, Khandelwal K (2014) Gurson model parameters for ductile fracture simulation in ASTM A992 steels. Fatigue\& Fract Eng Mater \& Struct 37:171–183

Oh Y-R, Nam H-S, Kim Y-J, Miura N (2018) Application of the GTN model to ductile crack growth simulation in through-wall cracked pipes. Int J Press Vessel Pip 159:35–44

de Sá JMAC, Areias PMA, Zheng C (2006) Damage modelling in metal forming problems using an implicit non-local gradient model. Comput Methods Appl Mech Eng 195:6646–6660

Park J, Lee K, Kang J-H et al (2021) Hierarchical microstructure based crystal plasticity-continuum damage mechanics approach: model development and validation of rolling contact fatigue behavior. Int J Plast 143:103025. https://doi.org/10.1016/j.ijplas.2021.103025

Acknowledgments

The present work has been supported by Hyundai Motor Company, which is greatly appreciated by all authors. Also, parts of the paper were based on the results from KEIT (No. 20010717) and NRF (Grant No. 2019R1A5A6099595 (ERC) and 2020R1A2B5B01097417). C. Kim appreciates the program of CRÈME supported by KIAT (No. P0002019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Basak, S., Kim, C., Jung, Y.I. et al. Analyses of shearing mechanism during shear-cutting of 980 MPa dual-phase steel sheets using ductile fracture modeling and simulation. Int J Mater Form 15, 4 (2022). https://doi.org/10.1007/s12289-022-01654-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-022-01654-y