Abstract

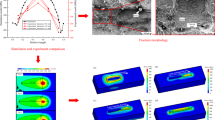

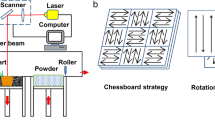

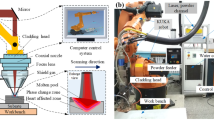

Thin-walled parts has been extensively used in the field of aerospace, refrigeration and electronic equipment for its characteristics of lightweight, material-saving and compact-structure. Selective laser melting (SLM) technology has been regarded as an effective way to manufacture parts with complex structures due to its high flexibility and efficiency. In this work, tungsten thin-walled parts are manufactured at different laser energy densities, and the finite element modelling of manufacturing process is combined with densification, dimensional accuracy and surface roughness measurement to optimize the SLM process parameters of tungsten thin-walled parts. The results indicated that the transient temperature peak is higher at the top position than at the bottom during the manufacturing process of thin-walled parts, which is also the same in the roughness. With the increase of laser energy input, the temperature of the molten pool is improved, which leads to an increment in the wall thickness. A sample with a maximum relative density of 84.5% was obtained at the optimal energy density about 1000 J/mm and its surface morphology exhibits fewer pores and cracks. The sample prepared at the laser energy input of 800 J/m exhibits the superior property of microhardness with the value of 504.3HV0.2. All these results are significant in the manufacture of thin-walled parts with high performances.

Similar content being viewed by others

References

Moitra A, Kim S, Kim SG, Park SJ, German RM, Horstemeyer MF (2010) Investigation on sintering mechanism of nanoscale tungsten powder based on atomistic simulation. Acta Mater 58:3939–3951. https://doi.org/10.1016/j.actamat.2010.03.033

Ren C, Fang ZZ, Koopman M, Butler B, Paramore J, Middlemas S (2018) Methods for improving ductility of tungsten – a review. Int J Refractory Metals Hard Mat 75:170–183. https://doi.org/10.1016/j.ijrmhm.2018.04.012

Huang WJ, Sun M, Yang JF, Wen W, Fang QF (2020) Microstructure evolution of pure tungsten after low-energy and high-fluence he+ implantation assessed by synchrotron grazing incidence X-ray diffraction. J Nucl Mater 544:1–9. https://doi.org/10.1016/j.jnucmat.2020.152663

Liu Y, Zhang J, Pang ZC, Wu WH (2018) Investigation into the influence of laser energy input on selective laser melted thin-walled parts by response surface method. Opt Lasers Eng 103:34–45. https://doi.org/10.1016/j.optlaseng.2017.11.011

Boegelein T, Louvis E, Dawson K, Tatlock GJ, Jones AR (2016) Characterisation of a complex thin walled structure fabricated by selective laser melting using a ferritic oxide dispersion strengthened steel. Mat Character 112:30–40. https://doi.org/10.1016/j.matchar.2015.11.021

Arash A, Li YC, Wen CE (2019) A comparative study on the nanoindentation behavior, wear resistance and in vitro biocompatibility of SLM manufactured CP-Ti and EBM manufactured Ti64 gyroid scaffolds. Acta Biomater 97:587–596. https://doi.org/10.1016/j.actbio.2019.08.008

Tang X, Zhang S, Zhang CH, Chen J, Zhang JB, Liu Y (2020) Optimization of laser energy density and scanning strategy on the forming quality of 24CrNiMo low alloy steel manufactured by SLM. Mater Charact 170(110718). https://doi.org/10.1016/j.matchar.2020.110718

Liu P, Hu JY, Li HX, Sun SY, Zhang YB (2020) Effect of heat treatment on microstructure, hardness and corrosion resistance of 7075 Al alloys fabricated by SLM. J Manuf Process 60:578–585. https://doi.org/10.1016/j.jmapro.2020.10.071

Papazoglou EL, Karkalos NE, Markopoulos AP (2020) A comprehensive study on thermal modeling of SLM process under conduction mode using FEM. Int J Adv Manuf Technol 111(9-10):2939–2955. https://doi.org/10.1007/s00170-020-06294-7

Ge JG, Huang J, Lei YP, O'Reilly P, Ahmed M, Zhang C, Yan XC, Yin S (2020) Microstructural features and compressive properties of SLM Ti6Al4V lattice structures. Surf Coat Technol 403:126419. https://doi.org/10.1016/j.surfcoat.2020.126419

Guo M, Gu DD, Xi LX, Zhang HM, Zhang JY, Yang JK, Wang R (2019) Selective laser melting additive manufacturing of pure tungsten: role of volumetric energy density on densification, microstructure and mechanical properties. Int J Refract Met Hard Mater 84:105025. https://doi.org/10.1016/j.ijrmhm.2019.105025

Ivekovic A, Montero-Sistiaga ML, Vanmeensel K, Kruth JP, Vleugels J (2019) Effect of processing parameters on microstructure and properties of tungsten heavy alloys fabricated by SLM. Int J Refract Met Hard Mater 82:23–30. https://doi.org/10.1016/j.ijrmhm.2019.03.020

Enneti RK, Morgan R, Atre SV (2017) Effect of process parameters on the selective laser melting (SLM) of tungsten. Int J Refract Met Hard Mater 71:315–319. https://doi.org/10.1016/j.ijrmhm.2017.11.035

Yuan LH, Gu DD, Lin KJ, Ge Q, Shi XY, Wang HR, Hu KM (2020) Influence of structural features on processability, microstructures, chemical compositions, and hardness of selective laser melted complex thin-walled components. Int J Refract Met Hard Mater 109:1643–1654. https://doi.org/10.1007/s00170-020-05773-1

Xie YJ, Yang HC, Wang XB, Zhao L, Han W (2019) Control of wall thickness and surface morphology of tungsten thin wall parts by adjusting selective laser melting parameters. J Iron Steel Res Int 26:182–190. https://doi.org/10.1007/s42243-019-00234-w

Wu F, Sun ZG, Li BY, Chen H, Guo SD, Zhu YB (2019) Influence of laser energy input on fabricating pure tungsten thin wall grids by selective laser melting. Mat ResExpress 6(12):126526. https://doi.org/10.1088/2053-1591/ab45b0

Mirkoohi E, Tran HC, Lo YL, Chang YC, Lin HY, Liang SY (2020) Analytical modeling of residual stress in laser powder bed fusion considering Part’s boundary condition. Crystals. 10(4):337–351. https://doi.org/10.3390/cryst10040337

Luo ZB, Zhao YY (2019) Numerical simulation of part-level temperature fields during selective laser melting of stainless steel 316L. Int J Adv Manuf Technol 104:1615–1635. https://doi.org/10.1007/s00170-019-03947-0

Okten K, Biyikoglu A (2021) Development of thermal model for the determination of SLM process parameters. Opt Laser Technol 137:106825. https://doi.org/10.1016/j.optlastec.2020.106825

Dong J, Liu SC, Chen H, Li D, Zhang TM, Chen C, Zhou KC (2020) Effect of atmosphere on the microstructure and properties of additively manufactured tungsten. Mater Sci Technol 36(18):1988–1996. https://doi.org/10.1080/02670836.2020.1852680

Tan CL, Zhou KS, Ma WY, Attard B, Zhang PP, Kuang TC (2018) Selective laser melting of high-performance pure tungsten: parameter design, densification behavior and mechanical properties. Sci Technol Adv Mater 19(1):370–380. https://doi.org/10.1080/14686996.2018.1455154

Acknowledgement

This research was supported by “the Fundamental Research Funds for the Central Universities”, grant number: JUSRP121041.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, X., Liu, X., Ren, S. et al. Selective laser melting fabricated tungsten with thin-walled structure: role of linear energy density on temperature evolution and manufacturing quality. Int J Mater Form 15, 2 (2022). https://doi.org/10.1007/s12289-021-01646-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12289-021-01646-4