Abstract

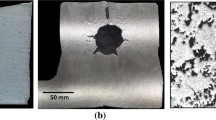

Most commercial softwares simulating casting process use a scalar field to quantify the shrinkage on final parts. The repartition of this scalar is used to localize shrinkage in the part. In this work, the objective is to use a new approach to predict morphological information about size and shape of shrinkage: the phase field method. This method is based on a parameter order defining the alternating zones metal/gas. Starting with a uniform unit value of this scalar, the phase field equation is modified with a nucleation process predicting the growth of the air phase into the metal one still liquid. The coupling with the Navier-Stokes equation brings up some interesting non-dimensional parameters that affect shrinkage morphology. This is what we have tried to analyse after proposing the modified phase fields formalism. Even if we are not yet in the predictive stage, we present in the end of this paper a numerical/experimental comparison showing the potentiality of the developed approach.

Similar content being viewed by others

References

Khan JG, Rajkolhe R (2014) Defects causes and their remedies in casting process: a review. International Journal of Research in Advent Technology 2:03

Ignaszak Z, Hajkowski J (2015) Contribution to the identification of porosity type in alsicu high-pressure-die-castings by experimental and virtual way

Ignaszak Z, Popielarski P, Hajkowski J, Prunier JB (2012) Problem of acceptability of internal porosity in semi-finished cast product as new trend tolerance of damage present in modern design office. In: Diffusion in solids and liquids VII, volume 326 of defect and diffusion forum, pages 612–619. Trans. Tech. Publications Ltd, 5

Tavakoli R (2010) On the prediction of shrinkage defects by thermal criterion functions

Kang M, Gao H, Wang J, Ling L, Sun B (2013) Prediction of microporosity in complex thin-wall castings with the dimensionless niyama criterion. Materials 6(5):1789–1802

Carlson K, Beckermann C (2008) Use of the niyama criterion to predict shrinkage-related leaks in high-nickel steel and nickel-based alloy castings 01

Gremaud Ch. Pequet M, Rappaz M (2002) Modeling of microporosity, macroporosity, and pipe-shrinkage formation during the solidification of alloys using a mushy-zone refinement method: applications to aluminum alloys. Metallurgical and Materials Transactions 33A:213–240, 07

Wang S-L, Sekerka RF, Wheeler AA, Murray BT, Coriell SR, Braun RJ, McFadden GB (1993) Thermodynamically-consistent phase-field models for solidification. Physica D: Nonlinear Phenomena 69(1):189–200

Warren J, Kobayashi R, Lobkovsky A, Carter W (2003) Extending phase field models of solidification to polycrystalline materials. Acta Materialia 51:6035–6058, 12

Landheer H, Offerman S, Petrov R, Kestens L (2009) The role of crystal misorientations during solid-state nucleation of ferrite in austenite. Acta Materialia - Acta Mater 57:1486–1496, 03

Abrivard G (2009) A coupled crystal plasticity - phase field formulation to describe microstructural evolution in polycrystalline aggregates during recrystallisation. Theses, École Nationale Supérieure des Mines de Paris

Suzuki T, Ode M, Kim SG, Kim WT (2002) Phase-field model of dendritic growth. The thirteenth international conference on Crystal Growth in conj unction with the eleventh international conference on Vapor Growth and Epitaxy, vol 237-239, pp 125–131

Dreyer W, Müller WH (2000) A study of the coarsening in tin/lead solders. Int J Solids Struct 37(28):3841–3871

del Pino M, Kowalczyk M, Wei J (2013) Entire solutions of the allen-cahn equation and complete embedded minimal surfaces of finite total curvature in \(\mathbb {R}^{3}\). J Differential Geom 93(1):67–131, 01

Cahn JW, Hilliard JE (1958) Free energy of a nonuniform system. i. interfacial free energy. J Chem Phys 28:258

CARLSON A, Do-Quang M, Amberg G (2011) Dissipation in rapid dynamic wetting. Journal of Fluid Mechanics 682:213–240, 09

Badalassi VE, Ceniceros HD, Banerjee S (2003) Computation of multiphase systems with phase field models. J Comput Phys 190(2):371–397

Rokkam S, El-Azab A, Millett P, Wolf D (2009) Phase field modeling of void nucleation and growth in irradiated metals. Modelling and Simulation in Materials Science and Engineering 17(6):064002

Ding X, Zhao J, Huang H, Ding S, Huo Y (2016) Effect of damage rate on the kinetics of void nucleation and growth by phase field modeling for materials under irradiations. J Nucl Mater 480:120–128

Millett PC, Rokkam S, El-Azab A, Tonks M, Wolf D (2009) Void nucleation and growth in irradiated polycrystalline metals: a phase-field model. Modelling and Simulation in Materials Science and Engineering 17(6):064003

Jacqmin D (1999) Calculation of two-phase navier–stokes flows using phase-field modeling. J Comput Phys 155(1):96–127

Chen W, Wang C, Wang X, Wise SM (2019) Positivity-preserving, energy stable numerical schemes for the cahn-hilliard equation with logarithmic potential. Journal of Computational Physics: X 3:100031

Kay D, Welford R (2006) A multigrid finite element solver for the cahn–hilliard equation. J Comput Phys 212(1):288–304

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jalouli, Z., Caillaud, A., Artozoul, J. et al. Modelling of shrinkage formation in casting by the phase field method. Int J Mater Form 14, 885–899 (2021). https://doi.org/10.1007/s12289-020-01602-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01602-8