Abstract

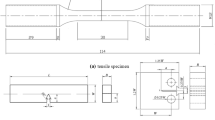

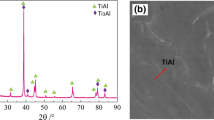

It is vital to envisage accurately the fracture limits of high strength superalloys when noticeable localized necking or thinning tendency is not observed during sheet-metal stretch forming process. The present study mainly focuses on fracture limits evaluation of Inconel 718 alloy (IN718) in the effective plastic strain (EPS) vs. average triaxiality space. First, uniaxial tensile test, to analyze the material properties, were instigated at different test temperatures (RT-700 °C). Subsequently, stretch forming is performed to evaluate forming and fracture forming limit diagrams (FLD and FFLD) of IN718 using Nakazima test. It is observed that forming and fractured limits of IN718 are significantly influenced by variation of processing temperatures (with approximately 65–70% improvement in major safe and fracture strains) in all deformation regions (with respect to RT). In average triaxiality (η) vs effective plastic strain (EPS) space, higher fracture limits of IN718 are noticed in the entire triaxiality path of deformation region. Seven different ductile fracture models, namely McClintock (M-Mc), Brozzo, Rice-Tracey (R-T), Ko, Oh, Cockcroft and Latham (C-L), and Clift, are formulated so as to foresee the fracture loci of IN718 in EPS vs. triaxiality space. Overall, Oh model, showed best predictability at all temperatures with least Average absolute error (AAE < 13.5%).

Similar content being viewed by others

Data Availability

Not applicable.

References

Schafrik RE, Ward DD, Groh JR (2001) Application of alloy 718 in GE aircraft engines: past, present and next five years. In: Superalloys 718, 625, 706 and various derivatives

Lawrence H. Thaller AHZ (2003) Overview of the design, development, and application of nickel-hydrogen batteries, NASA Tech. National Aeronautics and Space Administration, Glenn Research Center

Mahalle G, Kotkunde N, Kumar Gupta A, Kumar Singh S (2018) Study of mechanical properties and microstructural analysis for inconel alloy sheet at elevated temperature. Mater Today Proc 5(9):18016–18023. https://doi.org/10.1016/j.matpr.2018.06.135

Thomas A, El-Wahabi M, Cabrera JM, Prado JM (2006) High temperature deformation of Inconel 718. J Mater Process Technol 177(1-3):469–472. https://doi.org/10.1016/j.jmatprotec.2006.04.072

Mahalle G, Kotkunde N, Gupta AK, Singh SK (2019) Analysis of hot workability of Inconel alloys using processing maps. In: Advances in computational methods in manufacturing. Springer, pp 109–118

Reed RC (2006) The Superalloys fundamentals and applications. Cambridge University Press, New York

Panicker SS, Singh HG, Panda SK, Dashwood R (2015) Characterization of tensile properties, limiting strains, and deep drawing behavior of AA5754-H22 sheet at elevated temperature. J Mater Eng Perform 24(11):4267–4282. https://doi.org/10.1007/s11665-015-1740-6

Kotkunde N, Badrish A, Morchhale A, Takalkar P, Singh SK (2019) Warm deep drawing behavior of Inconel 625 alloy using constitutive modelling and anisotropic yield criteria. Int J Mater Form 13(3):1–15. https://doi.org/10.1007/s12289-019-01505-3

Badrish CA, Kotkunde N, Mahalle G, Singh SK, Mahesh K (2019) Analysis of hot anisotropic tensile flow stress and strain hardening behavior for Inconel 625 alloy. J Mater Eng Perform 28(12):7537–7553. https://doi.org/10.1007/s11665-019-04475-4

Prasad SK, Panda SK, Kar SK et al (2017) Microstructures, forming limit and failure analyses of Inconel 718 sheets for fabrication of aerospace components. J Mater Eng Perform 26(4):1513–1530. https://doi.org/10.1007/s11665-017-2547-4

Jafarian F, Masoudi S, Soleimani H, Umbrello D (2018) Experimental and numerical investigation of thermal loads in Inocnel 718 machining. Mater Manuf Process 23(9):1020–1029. https://doi.org/10.1080/10426914.2018.1424907

Kuroda M, Tvergaard V (2000) Forming limit diagrams for anisotropic metal sheets with different yield criteria. Int J Solids Struct 37(37):5037–5059. https://doi.org/10.1016/S0020-7683(99)00200-0

Basak S, Panda SK (2019) Failure strains of anisotropic thin sheet metals: experimental evaluation and theoretical prediction. Int J Mech Sci 151:356–374. https://doi.org/10.1016/j.ijmecsci.2018.10.065

Basak S, Panda SK, Zhou YN (2015) Formability assessment of prestrained automotive grade steel sheets using stress based and polar effective plastic strain-forming limit diagram. J Eng Mater Technol Trans ASME 137(4):1–12. https://doi.org/10.1115/1.4030786

Prasad KS, Panda SK, Kar SK, Murty SVSN, Sharma SC (2018) Prediction of fracture and deep drawing behavior of solution treated Inconel-718 sheets: numerical modeling and experimental validation. Mater Sci Eng A 733:393–407. https://doi.org/10.1016/j.msea.2018.07.007

Bruschi S, Altan T, Banabic D, Bariani PF, Brosius A, Cao J, Ghiotti A, Khraisheh M, Merklein M, Tekkaya AE (2014) Testing and modelling of material behaviour and formability in sheet metal forming. CIRP Ann Manuf Technol 63(2):727–749. https://doi.org/10.1016/j.cirp.2014.05.005

Güler B, Efe M (2018) Forming and fracture limits of sheet metals deforming without a local neck. J Mater Process Technol 252:477–484. https://doi.org/10.1016/j.jmatprotec.2017.10.004

Roamer P, Van Tyne CJ, Matlock DK et al (1997) Room temperature formability of alloys 625LCF, 718 and 718SPF. Miner Met Mater Soc:315–329. https://doi.org/10.7449/1997/superalloys_1997_315_329

Dilmec M, Halkaci HS, Ozturk F, Livatyali H, Yigit O (2013) Effects of sheet thickness and anisotropy on forming limit curves of AA2024-T4. Int J Adv Manuf Technol 67(9-12):2689–2700. https://doi.org/10.1007/s00170-012-4684-0

Banabic D (2010) A review on recent developments of Marciniak-Kuczynski model. Comput Methods Mater Sci 10:225–237

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46(1):81–98. https://doi.org/10.1016/j.ijmecsci.2004.02.006

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214(8):1557–1565. https://doi.org/10.1016/j.jmatprotec.2014.02.026

Park N, Huh H, Lim SJ, Lou Y, Kang YS, Seo MH (2017) Fracture-based forming limit criteria for anisotropic materials in sheet metal forming. Int J Plast 96:1–35. https://doi.org/10.1016/j.ijplas.2016.04.014

Takuda H, Mori K, Hatta N (1999) The application of some criteria for ductile fracture to the prediction of the forming limit of sheet metals. J Mater Process Technol 95(1-3):116–121. https://doi.org/10.1016/S0924-0136(99)00275-7

Wu Z, Li S, Zhang W, Wang W (2010) Ductile fracture simulation of hydropiercing process based on various criteria in 3D modeling. Mater Des 31(8):3661–3671. https://doi.org/10.1016/j.matdes.2010.02.046

Bai Y, Wierzbicki T (2015) A comparative study of three groups of ductile fracture loci in the 3D space. Eng Fract Mech 135:147–167. https://doi.org/10.1016/j.engfracmech.2014.12.023

Bai Y, Teng X (2009) On the application of stress triaxiality formula for plane strain fracture testing. J Eng Mater Technol 131(2):1–10. https://doi.org/10.1115/1.3078390

Mahalle G, Salunke O, Kotkunde N, Gupta AK, Singh SK (2019) Neural network modeling for anisotropicmechanical properties and work hardeningbehavior of Inconel 718 alloy at elevatedtemperatures. J Mater Res Technol 8(2):2130–2140. https://doi.org/10.1016/j.jmrt.2019.01.019

Mahalle G, Kotkunde N, Gupta AK, Sujith R, Singh SK, Lin YC (2019) Microstructure characteristics and comparative analysis of constitutive models for flow stress prediction of Inconel 718 alloy. J Mater Eng Perform 28(6):3321–3321. https://doi.org/10.1007/s11665-019-04116-w

Hecker SS (1975) Simple technique for determining forming limit curves. Sheet Met Ind 52:671–676

Charpentier PL (1975) Influence of punch curvature on the stretching limits of sheet steel. Metall Trans A 6(8):1665–1669. https://doi.org/10.1007/BF02641986

Mahalle G, Morchhale A, Kotkunde N, Gupta AK, Singh SK, Lin YC (2020) Forming and fracture limits of IN718 alloy at elevated temperatures: experimental and theoretical investigation. J Manuf Process 56:482–499. https://doi.org/10.1016/j.jmapro.2020.04.070

Cheng C, Meng B, Han JQ, Wan M, Wu XD, Zhao R (2017) A modified Lou-Huh model for characterization of ductile fracture of DP590 sheet. Mater Des 118:89–98. https://doi.org/10.1016/j.matdes.2017.01.030

Ko YK, Lee JS, Huh H, Kim HK, Park SH (2007) Prediction of fracture in hub-hole expanding process using a new ductile fracture criterion. J Mater Process Technol 187–188:358–371. https://doi.org/10.1016/j.jmatprotec.2006.11.071

Oh SI, Chen CC, Kobayashi S (1979) Ductile fracture in axisymmetric extrusion and drawing: part 2 workability in extrusion and drawing. J Manuf Sci Eng Trans ASME 101(1):36–44. https://doi.org/10.1115/1.3439471

Clift SE, Hartley P, Sturgess CEN, Rowe GW (1990) Fracture prediction in plastic deformation processes. Int J Mech Sci 32(1):1–17. https://doi.org/10.1016/0020-7403(90)90148-C

Cockcroft MG, Lathan DJ (1968) Ductility and the workability of metals. In: J. Inst. Met. https://books.google.co.in/books/about/Ductility_and_the_Workability_of_Metals.html?id=COSPAQAACAAJ&redir_esc=y. Accessed 18 Oct 2019

Mahalle G, Salunke O, Kotkunde N et al (2019) Anisotropic yielding behaviour of Inconel 718 alloy at elevated temperatures. In: ASME international mechanical engineering congress and exposition, proceedings (IMECE2019). Salt Lake City, Utah, USA, pp 1–5

McClintock FA (1964) A criterion for ductile fracture by the growth of holes. J Appl Mech Trans ASME 35(2):363–371. https://doi.org/10.1115/1.3601204

Samantaray D, Mandal S, Bhaduri AK (2009) A comparative study on Johnson cook, modified Zerilli-Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr-1Mo steel. Comput Mater Sci 47(2):568–576. https://doi.org/10.1016/j.commatsci.2009.09.025

Che J, Zhou T, Liang Z, Wu J, Wang X (2018) An integrated Johnson–cook and Zerilli–Armstrong model for material flow behavior of Ti–6Al–4V at high strain rate and elevated temperature. J Brazilian Soc Mech Sci Eng 40(5):1–10. https://doi.org/10.1007/s40430-018-1168-7

Acknowledgements

Authors are thankful for financial assistance given by the Government of India, Science and Engineering Research Board (SERB-DST ECR) (Sanction Number: ECR/2016/001402).

Funding

Science and Engineering Research Board (SERB-DST ECR) (Sanction Number: ECR/2016/001402).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest/Competing interest

No Conflict of interest

Code availability

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mahalle, G., Kotkunde, N., Gupta, A.K. et al. Comparative assessment of failure strain predictions using ductile damage criteria for warm stretch forming of IN718 alloy. Int J Mater Form 14, 799–812 (2021). https://doi.org/10.1007/s12289-020-01588-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01588-3