Abstract

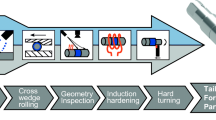

Within the Collaborative Research Centre (CRC) 1153 “Tailored Forming “the manufacturing of hybrid bulk components is investigated. Therefore, a process chain consisting of joining, forming, milling and quality control has been established by multiple subprojects. Within subproject B1 of the CRC forming of hybrid parts by the incrementally forming cross-wedge rolling (CWR) process is investigated. The superior aim is to determine process limits and capabilities, when forming parts consisting of different materials joined by varying technologies.

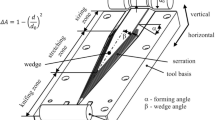

In this paper, the investigation of cross-wedge rolling of serially arranged hybrid parts made of steel and aluminium is described. The focus of the research presented in this publication is the displacement of the joining zone of hybrid parts due to the cross-wedge rolling process. Therefore, finite element simulations have been developed, that allow the investigations of hybrid solid components. After simulation of various variations of the cross-wedge rolling process, i.e. differently shaped tools and forming velocities, experimental trials were carried out with identical parameter sets. A comparison of simulation and experiment, showed that the simulation model is capable of describing the cross-wedge rolling process of hybrid parts. The standard deviation of the displacement of the joining zone between simulation and experimental trials is 8.8% with regard to all investigated cases.

Similar content being viewed by others

References

Assunção E, Quintino L, Miranda R (2009) Comparative study of laser welding in tailor blanks of the automotive industry. Int J Adv Manuf Technol 49(1-4):123–131. https://doi.org/10.1007/s00170-009-2385-0

Babic Z, Aleksandrović S, Stefanović M, Sljivic M (2008) Determination of tailor welded blanks formability characteristics. Journal for Technology of Plasticity 33: 39–47

Han SW, Hwang TW, Oh IY, Moon YH (2018) Feasibility studies on manufacturing tailored blanks by rolling partially stacked blanks. J Mech Sci Technol 32(4):15–75. https://doi.org/10.1007/s12206-018-0312-8

Kache H, Stonis M, Behrens BA (2013) Hybridschmieden. Monoprozessuales Umformen und Fügen metallischer Blech- und Massivelemente wt Werkstatttechnik online, vol 103, pp 257–262

Wesling V, Treutler K, Bick T, Stonis M, Langner J, Kriwall M (2018) Characteristics of joining and hybrid composite forging of aluminum solid parts and galvanized steel sheets. Conf Ser: Mater Sci Eng 373:012026. https://doi.org/10.1088/1757-899X/373/1/012026

Blohm T et al (2017) Investigation of the joining zone of laser welded and cross wedge rolled hybrid parts. Int J Mater Form. https://doi.org/10.1007/s12289-017-1393-0

Pater Z (2014) Cross-wedge rolling. In: Comprehensive materials processing, pp 211–279. https://doi.org/10.1016/B978-0-08-096532-1.00315-0

Li Q, Lovell M (2008) Cross wedge rolling failure mechanisms and industrial application. Int J Adv Manuf Technol 37(3–4):265–278. https://doi.org/10.1007/s00170-007-0979-y

Blohm T, Stonis M, Behrens BA (2015) Investigation of simulation parameters for cross wedge rolling titanium and Bainitic grade steel. J Appl Mech Mater 736:165–170

Knust J, Stonis M, Behrens BA (2016) Preform optimization for hot forging processes using an adaptive amount of flash based on the cross section shape complexity. Prod Eng 10(6). https://doi.org/10.1007/s11740-016-0702-7

Knust J, Podszus F, Stonis M, Behrens BA, Overmeyer L, Ullmann G (2016) Preform optimization for hot forging processes using genetic algorithms. Int J Adv Manuf Technol 85(5-8). https://doi.org/10.1007/s00170-016-9209-9

Blohm T, Langner J, Stonis M, Behrens BA (2017) Basic study of incremental forming of serially arranged hybrid parts using cross-wedge rolling. https://doi.org/10.1016/j.proeng.2017.10.921

Sun B, Xu J, Peng W, Shu X, Yin A, Huang G (2018) Experimental investigation on cross wedge rolling of composite 42CrMo/Q235 laminated shaft. Int J Adv Manuf Technol 96(1-4):895–903. https://doi.org/10.1007/s00170-017-1537-x

Pater Z, Tomczak J, Bulzak T (2017) New forming possibilities in cross wedge rolling processes. Archives of Civil and Mechanical Engineering 18(1). https://doi.org/10.1016/j.acme.2017.06.005

Pater Z, Tomczak J (2012) Experimental tests for cross wedge rolling of forgings made from non-ferrous metal alloys. Arch Metall Mater 4(4):919–928. https://doi.org/10.2478/v10172-012-0101-9

Li J, Wang B, Ji H, Huang X, Tang X, Ma W (2017) Effects of the cross-wedge rolling parameters on the formability of Ti–6Al–4V alloy. Int J Adv Manuf Technol 92(5–8):2217–2229. https://doi.org/10.1007/s00170-017-0263-8

Çakırcalı M, Kılıçaslan C, Güden M, Kıranlı E, Shchukin V, Petronko V (2013) Cross wedge rolling of a Ti6Al4V (ELI) alloy: the experimental studies and the finite element simulation of the deformation and failure. Int J Adv Manuf Technol 65(9–12):1273–1287. https://doi.org/10.1007/s00170-012-4256-3

Wensheng Y, Wang L, Tingxiang Y (2015) Experimental study on cross wedge rolling processes of aluminum alloy material. In: Proceedings of the. International Conference on Advanced Engineering Materials and Technology. Guangzhou, China, p 2015

Kozhevnikova GV (2012) Cross-wedge rolling - the physical-technical institute. Rue Publishing House

Li Q (2003) Characterization of failure mechanisms in cross wedge rolling. Dissertation, University of Pittsburgh

B.-A. Behrens, A. Chugreev, M. Selinski and T. Matthias (2019) Joining zone shape optimisation for hybrid components made of aluminium-steel by geometrically adapted joining surfaces in the friction welding process

Acknowledgements

The results presented in this paper were obtained within the Collaborative Research Centre 1153 (CRC 1153) “Process chain to produce hybrid high performance components by Tailored Forming” in the subproject B1. The authors would like to thank the German Research Foundation (DFG) for the financial and organisational support of this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kruse, J., Jagodzinski, A., Langner, J. et al. Investigation of the joining zone displacement of cross-wedge rolled serially arranged hybrid parts. Int J Mater Form 13, 577–589 (2020). https://doi.org/10.1007/s12289-019-01494-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-019-01494-3