Abstract

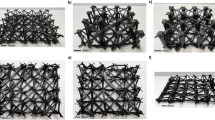

This paper presents a newly-developed billet flow formation method, which produces discontinuous carbon fiber thermoplastic ribbed panels by using the die cushion motion of a press. Billets of discontinuous fiber reinforced thermoplastic were extruded into rib cavities by die cushion motion while press-forming a panel of continuous fiber reinforced thermoplastic. Using billet flow formation, 200 mm long, 46 mm high, 1.4 mm thick ribs comprised of 30 mm long discontinuous fibers were formed on 400 mm wide, 300 mm depth, 50 mm high panels. The rigidity of a ribbed panel was five times greater than a panel without ribs. The tensile strength of the formed ribs was approximately 250 MPa, the same strength of the material before forming. Material behavior such as fiber flow and billet deformation during formation is discussed. This study has shown that the billet flow formation can create ribs with high mechanical strength using only a press with a die cushion.

Similar content being viewed by others

References

Morgan P (2005) Carbon fibers and their composites. Taylor & Francis

Möhring HC (2017) Composites in production machines. Procedia CIRP 66:2–9

Friedrich K, Almajid AA (2013) Manufacturing aspects of advanced polymer composites for automotive applications. Appl Compos Mater 20(2):107–128

Hou M (1996) Stamp forming of fabric-reinforced thermoplastic composites. Polym Compos 17(4):596–603

Allaoui S, Boisse P, Chatel S, Hamila N, Hivet G, Soulat D et al (2011) Experimental and numerical analyses of textile reinforcement forming of a tetrahedral shape. Compos Part A Appl Sci Manuf 42(6):612–622

Haanappel SP, Ten Thije RHW, Sachs U, Rietman B, Akkerman R (2014) Formability analyses of uni-directional and textile reinforced thermoplastics. Compos Part A Appl Sci Manuf 56:80–92

Behrens B-A, Raatz A, Hübner S, Bonk C, Bohne F, Bruns C et al (2017) Automated stamp forming of continuous Fiber reinforced thermoplastics for complex Shell geometries. Procedia CIRP 66:113–118

Yoneyama T, Tatsuno D, Kawamoto K, Okamoto M (2016) Effect of press slide speed and stroke on cup forming using a plain-woven carbon Fiber thermoplastic composite sheet. Int J Autom Technol 10(3):381–391

Harrison P, Gomes R, Curado-Correia N (2013) Press forming a 0/90 cross-ply advanced thermoplastic composite using the double-dome benchmark geometry. Compos Part A Appl Sci Manuf 54:56–69

Kim DH, Kim HG, Kim HS (2015) Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Compos Struct 131:742–752

Ning H, Vaidya U, Janowski GM, Husman G (2007) Design, manufacture and analysis of a thermoplastic composite frame structure for mass transit. Compos Struct 80(1):105–116

Joppich T, Menrath A, Henning F (2017) Advanced molds and methods for the fundamental analysis of process induced Interface bonding properties of hybrid, thermoplastic composites. Procedia CIRP 66:137–142

Kropka M, Muehlbacher M, Neumeyer T, Altstaedt V (2017) From UD-tape to final part – a comprehensive approach towards thermoplastic Composites. Procedia CIRP 66:96–100

Henning F, Ernst H, Brüssel R, Co G, Geiger O, Krause W et al (2005) LFTs for automotive applications. Reinf Plast 49(2):24–33

Franzén B, Klason C, Kubát J, Kitano T (1989) Fibre degradation during processing of short fibre reinforced thermoplastics. Composites 20(1):65–76

Thomason JL (2002) The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos Part A Appl Sci Manuf 33(12):1641–1652

Thomason JL, Vlug MA (1996) Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos Part A Appl Sci Manuf 27(6):477–484

Hou M, Ye L, Mai YW (1997) Manufacturing process and mechanical properties of thermoplastic composite components. J Mater Process Technol 63(1):334–338

Nowacki J, Neitzel M (2000) Thermoforming of reinforced thermoplastic stiffened structure. Polym Compos 21(4):531–538

Pappadà S, Salomi A, Montanaro J, Passaro A, Caruso A, Maffezzoli A (2015) Fabrication of a thermoplastic matrix composite stiffened panel by induction welding. Aerosp Sci Technol 43:314–320

Landry B, Hubert P (2015) Experimental study of defect formation during processing of randomly-oriented strand carbon/PEEK composites. Compos Part A Appl Sci Manuf 77:301–309

Wan Y, Takahashi J (2016) Tensile and compressive properties of chopped carbon fiber tapes reinforced thermoplastics with different fiber lengths and molding pressures. Compos Part A Appl Sci Manuf 87:271–281

Acknowledgements

This research is supported by the Center of Innovation Program from Japan Science and Technology Agency, JST.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tatsuno, D., Yoneyama, T., Kawamoto, K. et al. Billet flow formation of discontinuous carbon fiber ribbed square panels from continuous carbon fibers. Int J Mater Form 12, 145–160 (2019). https://doi.org/10.1007/s12289-018-1414-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-018-1414-7