Abstract

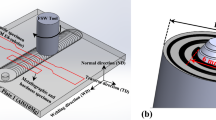

Self-reacting friction stir welding (SR-FSW), also called bobbin-tool friction stir welding (BT-FSW), is a solid state welding process similar to friction stir welding (FSW) except that the tool has two opposing shoulders instead of the shoulder and a backing plate found in FSW. The tool configuration results in greater heat input and a symmetrical weld macrostructure. A significant amount of information has been published in the literature concerning traditional FSW while little has been published about SR-FSW. An optimization experiment was performed using a factorial design to evaluate the effect of process parameters on the weld temperature, surface and internal quality, and mechanical properties of self-reacting friction stir welded aluminum alloy 6061-T6 butt joints. The parameters evaluated were tool rotational speed, traverse speed, and tool plunge force. A correlation between weld temperature, defect formation (specifically galling and void formation), and mechanical properties was found. Optimum parameters were determined for the welding of 8-mm-thick 6061-T6 plate.

Similar content being viewed by others

References

Mishra RS (2007) Friction stir welding and processing, 1st edn. ASM International, Materials Park

Esmaily M, Mortazavi N, Osikowicz W et al (2016) Bobbin and conventional friction stir welding of thick extruded AA6005-T6 profiles. Mater Des 108:114–125. doi:10.1016/j.matdes.2016.06.089

Chen SJ, Lu AL, Yang DL et al (2013) Analysis on flow pattern of bobbin tool friction stir welding for 6082 aluminum. In: Fujii H (ed) Proc. 1st Int. Jt. Symp. Join. Weld. Woodhead Publishing, Cambridge, pp 353–358

Srivatsan TS, Vasudevan S, Park L (2007) The tensile deformation and fracture behavior of friction stir welded aluminum alloy 2024. Mater Sci Eng A 466:235–245. doi:10.1016/j.msea.2007.02.100

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding – process, weldment structure and properties. Prog Mater Sci 53:980–1023. doi:10.1016/j.pmatsci.2008.05.001

Chao YJ, Qi X, Tang W (2003) Heat transfer in friction stir welding—experimental and numerical studies. J Manuf Sci Eng 125:138–145. doi:10.1115/1.1537741

Hwang Y-M, Kang Z-W, Chiou Y-C, Hsu H-H (2008) Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys. Int J Mach Tools Manuf 48:778–787. doi:10.1016/j.ijmachtools.2007.12.003

Adamowski J, Gambaro C, Lertora E et al (2007) Analysis of FSW welds made of aluminium alloy AW6082-T6. Arch Mater Sci Eng 28:453–460

Vilaça P, Quintino L, dos Santos JF (2005) iSTIR—analytical thermal model for friction stir welding. J Mater Process Technol 169:452–465. doi:10.1016/j.jmatprotec.2004.12.016

Woo W, Choo H, Withers PJ, Feng Z (2009) Prediction of hardness minimum locations during natural aging in an aluminum alloy 6061-T6 friction stir weld. J Mater Sci 44:6302–6309. doi:10.1007/s10853-009-3868-y

Sato YS, Urata M, Kokawa H (2002) Parameters controlling microstructure and hardness during friction-stir welding of precipitation-hardenable aluminum alloy 6063. Metall Mater Trans A 33:625–635. doi:10.1007/s11661-002-0124-3

Lityńska L, Braun R, Staniek G et al (2003) TEM study of the microstructure evolution in a friction stir-welded AlCuMgAg alloy. Mater Chem Phys 81:293–295. doi:10.1016/S0254-0584(02)00605-3

Elangovan K, Balasubramanian V (2008) Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater Charact 59:1168–1177. doi:10.1016/j.matchar.2007.09.006

Scialpi A, De Filippis LAC, Cavaliere P (2007) Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater Des 28:1124–1129. doi:10.1016/j.matdes.2006.01.031

Kumar K, Kailas SV (2008) The role of friction stir welding tool on material flow and weld formation. Mater Sci Eng A 485:367–374. doi:10.1016/j.msea.2007.08.013

Moreira PMGP, Santos T, Tavares SMO et al (2009) Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater Des 30:180–187. doi:10.1016/j.matdes.2008.04.042

Liu H, Fujii H, Maeda M, Nogi K (2003) Tensile properties and fracture locations of friction-stir welded joints of 6061-T6 aluminum alloy. J Mater Sci Lett 22:1061–1063. doi:10.1023/A:1024970421082

Vijayan S, Raju R, Subbaiah K et al (2010) Friction stir welding of al–mg alloy optimization of process parameters using Taguchi method. Exp Tech 34:37–44. doi:10.1111/j.1747-1567.2009.00563.x

Xu S, Deng X (2008) A study of texture patterns in friction stir welds. Acta Mater 56:1326–1341. doi:10.1016/j.actamat.2007.11.016

Liu HJ, Hou JC, Guo H (2013) Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061-T6 aluminum alloy. Mater Des 50:872–878. doi:10.1016/j.matdes.2013.03.105

Wang FF, Li WY, Shen J et al (2015) Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welding of al–li alloy. Mater Des 86:933–940. doi:10.1016/j.matdes.2015.07.096

Liu G, Murr LE, Niou C-S et al (1997) Microstructural aspects of the friction-stir welding of 6061-T6 aluminum. Scr Mater 37:355–361. doi:10.1016/S1359-6462(97)00093-6

Acknowledgments

The authors gratefully acknowledge the support of this research provided by the Materials and Processes Branch at NASA Johnson Space Center and Jacobs ESCG.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Trueba, L., Torres, M.A., Johannes, L.B. et al. Process optimization in the self-reacting friction stir welding of aluminum 6061-T6. Int J Mater Form 11, 559–570 (2018). https://doi.org/10.1007/s12289-017-1365-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-017-1365-4