Abstract

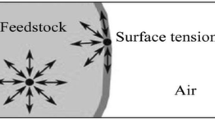

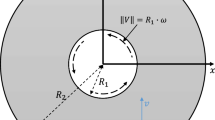

A single phase level set method for capturing the propagating front within textile unit-cells is presented. The computational domain is embedded within an artificial Cartesian grid in order to avoid the difficulties associated with the meshing step. The flow is modelled by using the Stokes/Brinkman equations. Hence, the necessity of describing the yarn boundaries is avoided. The propagating front is represented by using a level set formulation where the extra step of reinitialization is avoided. The flow equations are solved only in the filled part of the domain. The velocity in the unfilled part is obtained through a harmonic continuation. Numerical tests on simple configurations in 2D and 3D space are presented in order to demonstrate the proposed method.

Similar content being viewed by others

Notes

Although this statement is, in general, true, the LSM is notorious for not conserving the mass. A simple approach to improve this is to chose a different level set to represent the front based on whether mass is gained or lost. This approach however requires to reconstruct the flow front

It has to be noted here that the chosen finite element space is not in general appropriate to discretize the flow equations within the porous yarn, see for example [39] and references therein. The reason is that the ellipticity condition required to have a well posed saddle-point problem breaks down. Nonetheless, we do not address this point herein.

We remark here that \(\mathbf {u}_{h}\) is divided with the porosity of the yarn if the element has been categorized as a porous element, sub-section “Flow equations and approximation of geometry”.

References

Wong CC (2006) Modelling the effects of textile preform architecture on permeability. PhD thesis, University of Nottingham

Schell JSU, Deleglise M, Binetruy C, Krawczak P, Ermani P (2007) Numerical prediction and experimental characterization of meso-scale-voids in liquid composite moulding. Compos Part A 38:2460–2470

Tan H, Pillai MK (2010) Fast liquid composite molding simulation of unsaturated flow in dual-scale fiber mats using the imbibition characteristics of a fabric-based unit cell. Polym Compos 31:1790–1807

Judd NCW, Wright WW (1978) Voids and their effects on the mechanical properties of composites-an appraisal. Sampe J 14:10–14

Lundstrom ST, Gebart RB (1994) Influence from process parameters on void formation in rtm. Polym Compos 15:25–33

Rohtagi V, Patel N, Lee LJ (1996) Experimental investigation of flow-induced microvoids during impregnation of unidirectional stitched fiberglass mat. Polym Compos 17:161–170

Patel N, Lee LJ (1995) Effects of fiber mat architecture on void formation and removal in liquid composite molding. Polym Compos 16:386–399

Patel N, Rohtagi V, Lee LJ (1995) Micro scale flow behaviour and void formation mechanism during impregnation through a unidirectional stitched fiberglass mat. Polym Eng Sci 35(10):837–851

Chen TY, Macosko CW, Davis TH (1995) Numerical simulation for the transverse impregnation in resin transfer molding. AIChE 41:2274–2281

Chang YC, Hourng LW (1998) Wetting of fiber mats for composites manufacturing: Ii air entrapment model. J Reinf Plast Compos 17:165–182

Binetruy C, Hilaire B, Pabiot J (1997) The interactiobs between flows occuring inside and outside fabric tows during RTM. Compos Sci Technol 57:587–596

Ruiz E, Achim V, Soukane S, Trochu F, Bréard J (2006) Optimization of injection flow rate to minimize micro/macro-voids formation in resin transfer molded composites. Compos Sci Technol 66:475–486

Dimitrova Z, Advani SG (2004) Free boundary viscous flows at micro and mesolevel during liquid composites moulding process. Int J Numer Methods Fluids 46:435–455

Junying Y, Yuxi A, Sheng S, Dongjun M, Tongfei S, Lijia A (2006) Mesoscopic simulation of the impregnating process of unidirectional fibrous preform in resin transfer molding. Mater Sci Eng A 435–436:515–520

Liu HL, Hwang WR (2009) Transient filling simulations in unidirectional fibrous porous media. Korea-Australia Rheol J 21:71–79

DeValve C, Pitchumani R (2011) A numerical simulation of air entrapment during resin transfer molding. In: Proceedings SAMPE, Long Beach California

Brackbill JU, Kothe DB, Zemach C (1992) A continuum model for modeling surface tension. J Comput Phys 100:335–354

Pacquaut G, Bruchon J, Moulin N, Drapier S (2012) Combining a level set method and a mixed stabilized P1/P1 formulation for coupling Stokes-Darcy. Int J Numer Methods Fluids 69:459–480

Soukane S, Trochu F (2006) Application of the level set method to the simulation of resin transfer molding. Compos Sci Technol 66:1067–1080

Gantois R, Cantarel A, Dusserre G, Félices J-N, Schmidt F (2010) Numerical simulation of resin transfer molding using bem and level set method. Int J Mater Form 3:635–638

Smolianski A (2001) Numerical modeling of two-fluid interfacial flows. PhD thesis, University of Jyvaskyla

Ngo ND, Tamma KK (2001) Microscale permeability predictions of porous fibrous media. Int J Heat Mass Transf 44:3135–3145

Phelan FR, Leung Y, Parnas SR (1994) Modelling of microscale flow in unidirectional fibrous porous media. J Thermoplast Compos Mater 7:208–218

Ranganathan S, Phelan FR, Advani SG (1996) A generalized model for the transverse fluid permeability in unidirectional fibrous media. Polym Compos 17:222–230

Saliger AG, Aris R, Derby JJ (1994) Finite element formulations for large-scale coupled flows in adjacent porous and open fluid domains. Int J Numer Methods Fluids 18:1185–1209

Gartling KD, Hickox ED, Gilver CR (1996) Simulation of coupled viscous and porous flow problems. Comput Fluid Dyn 7:23–48

Martys N, Bentz PD, Garboczi J (1994) Computer simulation study of the effective viscosity in Brinkman’s equation. Phys Fluids 6:1434–1439

Verleye B (2008) Computation of the permeability of multi-scale porous media with application to technical textiles. PhD thesis, Katholique University of Leuven

Sherburn M (2007) Geometrical and mechanical modelling of textiles. PhD thesis, University of Nottingham

Osher SJ, Fedkiw RP (2002) Level set methods and dynamic implicit surfaces. Springer-Verlag

Owen HC (2009) A finite element model for free surface and two fluid flows on fixed meshes. PhD thesis, Universitat Politecnica de Catalunya

Ville L, Silva L, Coupez T (2011) Convected level set method for numerical simulation of fluid buckling. Int J Num Methods Fluids 66:324–344

Bui C, Frey P, Maury B (2011) A coupling strategy based on anisotropic mesh adaptation for solving two-fluid flows. Int J Numer Methods Fluids 66:1226–1247

Adalsteinsson D, Sethian JA (1997) The fast construction of extension velocities in level set methods. J Comput Phys 148:2–22

Dunne T (2007) Adaptive finite element approximation of fluid-structure interaction based on Eulerian and Arbitrary Lagrangian-Eulerian variational formulations. PhD thesis, Ruprecht Karls Universitat Heidelberg

Tiezheng Q, Xiap-Ping W, Ping S (2006) Molecular hydrodynamics of the moving contact line in two-phase immiscible flows. Comun Comput Phys 1:1–52

Bangerth W, Hartmann R, Kanchat G (2007) deal.II – a general purpose object oriented finite element library. ACM Trans Math Softw 33:24/1–24/27

Volker J (2002) Slip with friction penetration with resistance boundary conditions for the Navier-Stokes equations-numerical tests and aspects of the implementation. J Comput Appl Math 147:287–300

Elman H, Silvester DW, Wathen A (2005) Finite elements and fast iterative solvers with applications in incompressible fluid dynamics. Oxford Press

Giavaras A (2011) A finite element model for the permeability of textiles. PhD thesis, University of Nottingham

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giavaras, A., Boateng, E. Transient filling modelling at meso-level for RTM process using a single phase LSM. Int J Mater Form 8, 197–210 (2015). https://doi.org/10.1007/s12289-013-1160-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1160-9