Abstract

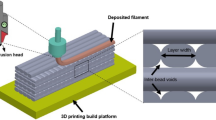

New trends in sheet metal forming are rapidly developing and several new forming processes have been proposed to accomplish the goals of flexibility and cost reduction. Among them, Incremental CNC sheet forming operations (ISF) are a relatively new sheet metal forming processes for small batch production and prototyping. In single point incremental forming (SPIF), the final shape of the component is obtained by the CNC relative movements of a simple and small punch which deform a clamped blank into the desired shape and which appear quite promising. No other dies are required than the ones used in any conventional sheet metal forming processes. As it is well known, the design of a mechanical component requires some decisions about the mechanical resistance and geometrical quality of the parts and the product has to be manufactured with a careful definition of the process set up. The use of computers in manufacturing has enabled the development of several new sheet metal forming processes, which are based upon older technologies. Although standard sheet metal forming processes are strongly controlled, new processes like single point incremental sheet forming can be improved. The SPIF concept allows to increase flexibility and to reduce set up costs. Such a process has a negative effect on the shape accuracy by initiating undesired rigid movement and sheet thinning. In the paper, the applicability of the numerical technique and the experimental test program to incremental forming of sheet metal is examined. Concerning the numerical simulation, a static implicit finite element code ABAQUS/Standard is used. These two techniques emphasize the necessity to control some process parameters to improve the final product quality. The reported approaches were mainly focused on the influence of four process parameters on the punch force trends generated in this forming process, the thickness and the equivalent plastic deformation distribution within the whole volume of the workpiece: the initial sheet thickness, the wall angle, the workpiece geometry and the nature of tool path contours controlled through CNC programming. The tool forces required to deform plastically the sheet around the contact area are discussed. The effect of the blank thickness and the tool path on the punch load and the deformation behaviour is also examined with respect to several tool paths. Furthermore, the force acting on the traveling tool is also evaluated. Similar to the sheet thickness, the effect of wall angle and part geometry on the load evolution, the distribution of calculated equivalent plastic strain and the variation of sheet thickness strain are also discussed. Experimental and numerical results obtained allow having a better knowledge of mechanical and geometrical responses from different parts manufactured by SPIF with the aim to improve their accuracy. It is also concluded that the numerical simulation might be exploited for optimization of the incremental forming process of sheet metal.

Similar content being viewed by others

References

Attanasio A, Ceretti E, Giardini C (2006) Optimization of tool path in two points incremental forming. J Mater Process Technol 177:409–412

Leszak E (1967) Apparatus and process for incremental dieless forming. Patent US 3342051A1

Matsubara S (2001) A computer numerically controlled dieless incremental forming of a sheet metal. In Proc of the Institution of Mechanical Engineers (IMECHE) part B. J Eng Manuf 215:959–966

Filice L, Fratini L, Micari F (2002) Analysis of material formability in incremental forming. Ann CIRP 51(1):199–202

Jeswiet J (2001) Incremental single point forming with a tool post. In Proc of the ninth International Conference on Sheet Metal (SheMet), Leuven, p 37–42

Amino H, Lu Y, Ozawa S, Fukuda K, Maki T (2002) Dieless NC forming of automotive service parts. In Proc of the seventh International Conference on Computational Plasticity (ITCP), Yokohama, p 1015–1020

Jeswiet J, Micari F, Hirt G, Bramley A, Duflou JR, Allwood J (2005) Asymmetric single point incremental forming of sheet metal. Ann CIRP—Manuf Technol 54(2):623–649

Jeswiet J (2005) Asymmetric incremental sheet forming. In Proc of the Eleventh International Conference on Sheet Metal (SheMet), Erlangen-Nuremberg, Germany, p 35–58

Hirt G, Junk S, Witulski N (2002) Incremental sheet forming: quality evaluation and process simulation. In Proc of the seventh International Conference on Computational Plasticity (ITCP), Yokohama, p 925–930

Ambrogio G, Filice L, De Napoli L, Muzzupappa M (2005) A simple approach for reducing profile diverting in a single point incremental forming process. In Proc of the Institution of Mechanical Engineers (IMECHE) part B. J Eng Manuf 219(11):823–830

Bambach M, Hirt G, Ames J (2005) Qualitative validation of FEM simulations for incremental sheet forming using optical deformation measurement. Adv Mater Res 6(8):509–516

Ambrogio G, Filice L, Fratini L, Micari F (2004) Process mechanics analysis in single point incremental forming. In Proc of the eighth International Conference on Numerical Methods in Industrial Forming Processes (NUMIFORM), p 922–927

Jeswiet J, Hagan E, Szekeres A (2002) Forming parameters for IF of aluminum sheet metal. J Eng Manuf 216:1367–1371

Fratini L, Ambrogio G, Di Lorenzo R, Filice L, Micari F (2004) Influence of mechanical properties of the sheet material on formability in single point incremental forming. Ann CIRP 53(1):207–210

Ham M, Jeswiet J (2006) Single point incremental forming and the forming criteria for AA3003. Ann CIRP—Manuf Technol 55(1):241–244

Ham M, Jeswiet J (2007) Single point incremental forming limits using a box-behnken design of experiment. Key Eng Mater 344:629–636

Ambrogio G, Duflou J, Filice L, Aerens R (2007) Some considerations on force trends in incremental forming of different materials. In Proc of the tenth International Conference on Material Forming (ESAFORM), p 193–198

Filice L, Ambrogio G, Micari F (2006) On-line control of single point incremental forming operations through punch force monitoring. Ann CIRP—Manuf Technol 55(1):245–248

Szekeres A, Ham M, Jeswiet J (2007) Force measurement in pyramid shaped parts with a spindle mounted force sensor. Key Eng Mater 344:551–558

Bambach M, Todorova M, Hirt G (2007) Experimental and numerical analysis of forming limits in CNC incremental sheet forming. Key Eng Mater 344:511–518

Allwood JM, Shouler DR, Tekkaya AE (2007) The increased forming limits of incremental sheet forming processes. Key Eng Mater 344:621–628

Emmens WC, Van den Boogaard AH (2007) Strain in shear and material behaviour in incremental forming. Key Eng Mater 344:519–526

Emmens WC, Van den Boogaard AH (2008) Tensile tests with bending: a mechanism for incremental forming. In Proc of the eleventh International Conference on Material Forming (ESAFORM)

Park JJ, Kim YY (2003) Fundamental studies on the incremental sheet metal forming technique. J Mater Process Technol 40:447–453

Livers WB, Pilkey AK, Lloyd DJ (2004) Using incremental forming to calibrate a void nucleation model for automotive aluminum sheet alloys. Acta Mater 52:3001–3007

Powell N, Andrew C (1992) Incremental forming of flanged sheet metal components without dedicated dies. In Proc of the Institution of Mechanical Engineers (IMECHE) part B. J Eng Manuf 206:41–47

Leach D, Green AJ, Bramley AN (2001) A new incremental sheet forming process for small batch and prototype parts. In Proc of the ninth International Conference on Sheet Metal (SheMet), Leuven, p 211–218

Jeswiet J (2000) Rapid proto-typing with incremental single point forming. CAD/CAM Comput Graphics 15:177–183

Matsubara S (1994) Incremental backward bulge forming of a sheet metal with a hemispherical head tool. J JSTP 35:1311–1316

Hagan E, Jeswiet J (2003) A review of conventional and modern single point sheet metal forming methods. In Proc of the Institution Of Mechanical Engineers (IMECHE) part B. J Eng Manuf 217:213–225

Jackson K, Allwood J (2009) The mechanics of incremental sheet forming. J Mater Process Technol 209:1158–1174

Bambach M, Hirt G, Junk S (2003) Modelling and experimental evaluation of the incremental CNC sheet metal forming process. In Proc of the seventh International Conference on Computational Plasticity (COMPLAS), Barcelona, Spain

Hirt G, Ames J, Bambach M, Kopp R (2004) Forming strategies and process modelling for CNC incremental sheet forming. Ann CIRP—Manuf Technol 53(1):203–206

Bambach M, Hirt G, Ames J (2004) Modeling of optimization strategies in the incremental CNC sheet metal forming process. In Proc of the eighth International Conference on Numerical Methods in Industrial Forming Processes (NUMIFORM), 712:1969–1974

Ambrogio G, Filice L, Gagliardi F, Micari F (2005) Three-dimensional FE simulation of single point incremental forming: experimental evidences and process design improving. In Proc of the eighth International Conference on Computational Plasticity (COMPLAS), Barcelona, Spain

Duflou JR, Verbert J, Belkassem B, Gu J, Sol H, Henrard C, Habraken AM (2008) Process window enhancement for single point incremental forming through multi-step toolpaths. Ann CIRP—Manuf Technol 57(1):253–256

Iseki H (2001) An approximate deformation analysis and FEM analysis for the incremental bulging of sheet metal using a spherical roller. J Mater Process Technol 111:150–154

Shim MS, Park JJ (2001) The formability of aluminum sheet in incremental forming. J Mater Process Technol 113:654–658

Yamashita M, Gotoh M, Atsumi SY (2008) Numerical simulation of incremental forming of sheet metal. J Mater Process Technol 199:163–172

Verbert J, Belkassem B, Henrard C, Habraken AM, Gu J, Sol H, Lauwers B, Duflou JR (2008) Multi-step toolpath approach to overcome forming limitations in single point incremental forming. Int J Mater Form 1:1203–1206

Wang H, Duncan SR, (2005) Model predictive based incremental sheet forming toolpath optimisation. In Review Literature And Arts Of The Americas

Rauch M, Hascoet JY, Hamann JC, Plenel Y (2009) Tool path programming optimization for incremental sheet forming applications. J Comput Aided Des 41(12):877–885

Robert C, Ben Ayed L, Delamézière A, Santo D, Batoz JL (2010) Development of a simplified approach of contact for incremental sheet forming. Int J Mater Form 3:987–990

Attanasio A, Ceretti E, Giardini C, Mazzonia L (2008) Asymmetric two points incremental forming: improving surface quality and geometric accuracy by tool path optimization. J Mater Process Technol 197:59–67

Iseki H, Kato K, Sakamoto S (1993) Forming limit of flexible and incremental sheet metal bulging with a spherical roller. In Proc of the fourth International Conference on Computational Plasticity (ITCP), Beijing, China, pp 1635–1640

Dai K, Wang ZR, Fang Y (2000) CNC incremental sheet forming of an axially symmetric specimen and the locus of optimization. J Mater Process Technol 102:164–167

Kim YH, Park JJ (2002) Effect of process parameters on formability in incremental forming of sheet metal. J Mater Process Technol 130(131):42–46

Pohlak M, Küttner R, Majak J, Karjust K, Sutt A (2004) Experimental study of incremental forming of sheet metal products. In Proc of the fourth International DAAAM Conference, Tallinn, Estonia

Pohlak M, Küttner R, Majak J, Karjust K, Sutt A (2004) Simulation of incremental forming of sheet metal products. In Proc of the fourth International DAAAM Conference, Tallinn, Estonia

Ambrogio G, De Napoli L, Filice L, Gagliardi F, Muzzupappa M (2005) Application of incremental forming process for high customised medical product manufacturing. J Mater Process Technol 162(163):156–162

Tanaka S, Nakamura T, Hayakawa K, Nakamura H, Motomura K (2005) Incremental sheet metal forming process for pure titanium denture plate. In Proc of the International Conference on Computational Plasticity (ITCP), Verona, Italy

Hirt G, Bambach M, Junk S, Chouvalova I (2003) FEM modelling and optimisation of geometric accuracy in incremental CNC sheet forming. In Proc of the tenth Saxon Conference on Forming Technology, Chemnitz, Germany

Kim TJ, Yang DY (2000) Improvement of formability for the incremental sheet metal forming process. Int J Mech Sci 42:1271–1286

Iseki H, Naganawa T (2002) Vertical wall surface forming of rectangular shell using multistage incremental forming with spherical and cylindrical rollers. J Mater Process Technol 130(131):675–679

Micari F, Ambrogio G (2004) A common shape for conducting incremental forming tests. In Proc of the first Incremental Forming Workshop, University of Saarbrucken, Germany

Young D, Jeswiet J (2004) Wall thickness variations in single-point incremental forming. J Eng Manuf 18(11):1453–1459

Duflou JR, Tunçkol Y, Szekeres A, Vanherck P (2007) Experimental study on force measurements for single point incremental forming. J Mater Process Technol 189:65–72

Van Bael A, Eyckens P, He S, Bouffioux C, Henrard C, Habraken AM, Duflou J, Van Houtte P (2007) Forming limit predictions for single-point incremental sheet metal forming. In Proc of the tenth International Conference on Material Forming (ESAFORM), Zaragosa, Spain

Hill R (1948) A theory of the yielding and plastic flow of anisotropic materials. In Proc of the Royal Society of London, A193:281–297

Jadhav S (2004) Basic investigations of the incremental sheet metal forming process on a CNC milling machine. Doctoral thesis, Universität Dortmund

Brown J (1998) Advanced machining technology handbook. McGraw Hill, New York

Pohlak M, Küttner R, Majak J (2004) Simulation of incremental forming processes of sheet metal. In Proc of the third International Conference on Advances in Production Engineering, Warsaw, Part II 133–140

Pohlak M, Küttner R, Majak J (2005) Modelling and optimal design of sheet metal RP&M processes. J Rapid Prot 11:304–311

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arfa, H., Bahloul, R. & BelHadjSalah, H. Finite element modelling and experimental investigation of single point incremental forming process of aluminum sheets: influence of process parameters on punch force monitoring and on mechanical and geometrical quality of parts. Int J Mater Form 6, 483–510 (2013). https://doi.org/10.1007/s12289-012-1101-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1101-z