Abstract

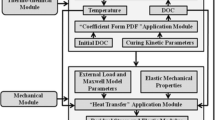

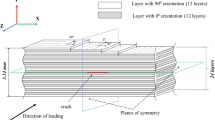

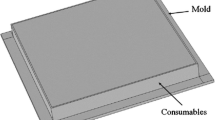

This paper is dedicated to the cure of an in-plane isotropic carbon-epoxy tooling material presenting a specific mesostructure. Eshelby-Kröner self-consistent model (EKSC) is used to achieve a two-steps scale transition procedure, allowing relating microscopic to macroscopic properties of the material, and estimating its multi-scale mechanical states. This procedure is used to predict the local residual stresses due to thermal and chemical shrinkage of the resin, depending on the manufacturing process conditions. An experimental investigation provides the BMI resin cure kinetics and mechanical properties as a function of the temperature and conversion degree. The consequences of these evolutions on the local mechanical states are investigated and discussed.

Similar content being viewed by others

References

Adolf DB, Chambers RS (1997) Verification of the capability for quantitative stress prediction during epoxy cure. Polymer 38(21):5481–5490

Bailleul JL (1997) Optimisation du cycle de cuisson des pièces épaisses en matériau composite. Application à un préimprégné résine époxyde/fibres de verre. Doctoral Thesis, University of Nantes

Berryman J, Berge P (1996) Critique of two explicit schemes for estimating elastic properties of multiphase composites. Mech Mater 22:149–164

Bogetti TA, Gillespie JW (1992) Process-induced stress and deformation in thick-section thermo-set composite laminates. J Compos Mater 26:626–659

Dillman SH, Seferis JC (1987) Kinetic viscoelasticity for the dynamic mechanical properties of polymer system. J Macromol Sci Pure Appl Chem 27:749–772

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc R Soc Lond A241:376–396

Etienne S, Cavaillé JY, Perez J, Salvia M (1982) Automatic system for analysis of micromechanical properties. Rev Sci Instrum 53:1261–1266

Feyel F, Chaboche JL (2000) FE2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials. Comput Meth Appl 183(3–4):309–330

Fiedler B, Hojo M, Ochiai S, Schulte K, Ando M (2001) Failure behavior of an epoxy matrix under different kinds of static loading. Compos Sci Technol 61:1615–1624

Fréour S, Gloaguen D, François M, Guillén R (2004) Thermal properties of polycrystals - X-ray diffraction and scale transition modelling. Phys Status Solidi 201:59–71

Fréour S, Jacquemin F, Guillén R (2005) On an analytical self-consistent model for internal stress prediction in fiber-reinforced composites submitted to hygroelastic load. J Reinforc Plast Compos 24:1365–1377

Fréour S, Jacquemin F, Guillén R (2006) Extension of Mori-Tanaka approach to hygroelastic loading of fiber-reinforced composites - Comparison with Eshelby-Kröner self-consistent model. J Reinf Plast Compos 25:1039–1053

Fréour S, Jacquemin F, Guillén R (2007) On the use of the geometric mean approximation in estimating the effective hygro-elastic behaviour of fiber-reinforced composites. J Mater Sci 42:7537–7543

Grandidier JC, Drapier S, Potier-Ferry M (2001) A structural approach of plastic microbuckling in long fibre composites: comparison with theoretical and experimental results. Int J Solid Struct 38:3877–3904

Ha SK, Jin KK, Huang Y (2008) Effects of fiber arrangement on mechanical behavior of unidirectional composites. J Compos Mater 42:1851–1871

Ha SK, Jin KK, Huang Y (2008) Micro-mechanics of failure (MMF) for continuous fiber reinforced composites. J Compos Mater 42:1873–1895

Hashin Z, Shtrikman S (1963) A variational approach to the elastic behavior of multiphase materials. J Mech Phys Solid 11:127–140

Hexcel Composites France (2010) Hexply M61 Datasheet, Hextool User Guide and Hextool DataSheet (www.hexcel.com/); internal reports and exchanges with C. Dauphin and M. Bonnafoux (Hexcel Composites France), unpublished results

Hill R (1967) The essential structure of constitutive laws for metals composites and polycrystals. J Mech Phys Solid 15:79–95

Jacquemin F, Fréour S, Guillén R (2005) A hygroelastic self-consistent model for fiber-reinforced composites. J Reinf Plast Compos 24:485–502

Jin KK, Huang Y, Lee YH, Ha SK (2008) Distribution of micro stresses and interfacial tractions in unidirectional composites. J Compos Mater 42:1825–1849

Kamal MR, Sourour S (1973) Kinetics and thermal characterization of thermosets cure. Polym Eng Sci 13:59–64

Kocks UF, Tomé CN, Wenk HR (1998) Texture and anisotropy. Cambridge University Press

Kröner E (1958) Berechnung der elastischen Konstanten des Vielkristalls aus des Konstanten des Einkristalls. Z Phys 151:504–508

Kugler D, Moon TJ (2002) Identification of the most significant processing parameters on the development of fiber waviness in thin laminates. J Compos Mater 36(12):1451–1479

Lacoste E, Fréour S, Jacquemin F (2010) On the validity of the self-consistent scale transition model for inclusions with varying morphologies. Mech Mater 42:218–226

Matsuoka M, Quan X, Bair HE, Boyle DJ (1989) A model for the curing reaction of epoxy resins. Macromolecules 22:4093–4098

Menard KP (1999) Dynamic mechanical analysis: a practical introduction. CRC, Boca Raton

Mori T, Tanaka K (1973) Average stress in the matrix and average elastic energy of materials with misfitting inclusions. Acta Metallurgica 21:571–574

Moulinec H, Suquet P (1998) A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput Meth Appl Mech Eng 157:69–94

Msallem YA (2008) Caractérisation thermique et mécanique d’un matériau composite aéronautique pendant le procédé d’élaboration – Contribution à l’estimation des contraintes résiduelles. Doctoral Thesis, Ecole Centrale de Nantes

Msallem YA, Jacquemin F, Boyard N, Poitou A, Delaunay D, Chatel S (2010) Material characterization and residual stresses simulation during the manufacturing process of epoxy matrix composites. Compos Appl Sci Manuf 41(1):108–115

Mura T (1982) Micromechanics of defects in solids. Martinus Nijhoff Publishers, The Hague

Niu K, Talreja R (2000) Modeling of compressive failure in fiber reinforced composites. Int J Solid Struct 37:2405–2428

Parlevliet PP, Bersee HEN, Beukers A (2006) Residual stresses in thermoplastic composites – a study of the literature. Part I: Formation of residual stresses. Compos Appl Sci Manuf 37:1847–1857

Parlevliet PP, Bersee HEN, Beukers A (2007) Residual stresses in thermoplastic composites – a study of the literature. Part II: Experimental techniques. Compos Appl Sci Manuf 38:651–665

Parlevliet PP, Bersee HEN, Beukers A (2007) Residual stresses in thermoplastic composites – a study of the literature. Part III: Effects of thermal residual stresses. Compos Appl Sci Manuf) 38:1581–1596

Pascault JP, Sautereau H, Verdu J, Williams R (2002) Thermosetting polymers. Marcel Dekker Inc. p. 157–196

Rabearison N, Jochum C, Grandidier JC (2009) A FEM coupling model for properties prediction during the curing of an epoxy matrix. Comput Mater Sci 45(3):715–724

Rosen VW (1965) Mechanics of composite strengthening. In: Fiber Composite Materials. American Society of Metals, Metals Park, Ohio, pp 37–75

Sanford WM, McCullough RL (1990) A free-volume-based approach to modeling thermoset cure behavior. J Polymer Sci, Part B: Polymer Phys 28:973–1000

Sbirrazzuoli N, Vyazovkin S (2002) Learning about epoxy cure mechanisms from isoconversional analysis of DSC data. Thermochim Acta 388(1–2):289–298

Schultheisz CR, Waas AM (1996) Compressive failure of composites, part I: testing and micromechanical theories. Prog Aerosp Sci 32(1):1–42

Schultheisz CR, Waas AM (1996) Compressive failure of composites, part II: Experimental studies. Prog Aerosp Sci 32(1):43–78

Terekhina S, Salvia M, Fouvry S (2011) Contact fatigue and wear behaviour of bismaleimide polymer subjected to fretting loading under various temperature conditions. Tribol Int 44(4):396–408

Tsai SW, Hahn HT (1980) Introduction to composite materials. Technomic, Westport

Welzel U, Fréour S, Mittemeijer EJ (2005) Direction-Dependent Elastic Grain-Interaction Models – A Comparative Study. Philos Mag 85:2391–2414

White SR, Kim KS (1998) Process-induced residual stress analysis of AS4/3501-6 composite material. Mech Compos Mater Struct 5:153–186

Zhao LG, Warrior NA, Long AC (2007) A thermo-viscoelastic analysis of process-induced residual stress in fibre-reinforced polymer-matrix composites. Mater Sci Eng, A 452–453:483–498

Acknowledgments

The authors wish to acknowledge C. Dauphin and M. Bonnafoux (from Hexcel Composites France) for the valuable information provided on the Hextool, and for the supplied materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lacoste, E., Szymanska, K., Terekhina, S. et al. A multi-scale analysis of local stresses development during the cure of a composite tooling material. Int J Mater Form 6, 467–482 (2013). https://doi.org/10.1007/s12289-012-1100-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1100-0