Abstract

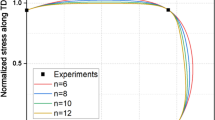

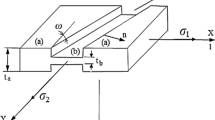

Process induced anisotropy in sheet metal is accounted for in analytical modeling by anisotropic yield criteria. The suitability of a yield criterion for predicting sheet metal forming process is generally validated by way of its ability to predict surface strains. However, the sensitivity of surface strains to yield criteria is dependent upon strain modes, with plane strain mode exhibiting higher sensitivity. To eliminate dependency on strain modes, stresses are used to evaluate yield criteria, since forming stresses are less sensitive to strain modes. In the study, the residual stresses remaining in a hemispherical cup formed in plain strain mode is predicted using Hill48 and Barlat89 criteria. The residual stresses are experimentally characterized by using X-Ray diffraction method. Suitable yield criterion for forming simulation is validated based on the correlation of theoretical predictions with experimental residual stress values.

Similar content being viewed by others

References

Banabic D, Aretz H, Comsa DS, Paraianu L (2005) An improved analytical description of orthotropy in metallic sheets. Int J Plastic 21:493–512

Banabic D, Bunge HJ, Pohlandt K, Tekkaya AE (2001) Formability of metallic materials: Plastic anisotropy, formability testing, forming limits. Springer publication

Banabic D, Kuwabara T, Balan T, Comsa DS (2004) An anisotropic yield criterion for sheet metals. J Mater Process Technol 157–158:462–465

Barlat F, Lian J (1989) Plastic behavior and stretchability of sheet metals. Part I- A Yield function for orthotropic sheets under plane stress conditions. Int J Plastic 5:51–66

Bruni C, Celeghini M, Geiger M, Gabrielli FA (2007) study of techniques in the evaluation of springback and residual stress in hydroforming. Int J Adv Manuf Technol 33:929–939

Buttle DJ, Dalzell W, Thayer PJ (2004) Early warnings of the onset of rolling contact fatigue by inspecting the residual stress environment of the railhead. Insight 46:344–348

Duchene L, Habraken AM (2005) Analysis of the sensitivity of FEM predictions to numerical parameters in deep drawing simulations. Eur J Mech A/Solids 24:614–629

Hill R (1950) Mathematical theory of Plasticity. Oxford

Hopperstad OS, Berstad T, Ilstad H, Lademo OG, Langseth M (1998) Effects of the yield criterion on local deformations in numerical simulation of profile forming. J Mater Process Technol 80–81:551–555

Iadicola MA, Foecke T, Stoughton TB. Experimental procedures and results for benchmark 3: Stage 2 forming process. In Numisheet 2005.

Kleinera M, Kruxa R, Homberga W (2004) Analysis of residual stresses in high-pressure sheet metal forming. CIRP Ann - Manuf Technol 53:211–214

Lee BH, Keum YT, Wagoner RH (2002) Modeling of the friction caused by lubrication and surface roughness in sheet metal forming. J Mater Process Technol 130–131:60–63

Liao KC, Pan J, Tang SC (1998) Effects of yield surface shape on sheet metal forming simulations. Int J Numeric Methods Eng 41:559–584

Logan RW, Hosford WF (1980) Upper-bound anisotropic yield locus calculations assuming <111> pencil glide. Int J Mech Sci 22:419–430

Mattiasson K, Sigvant M (2005) On The influence of the yield locus shape in the simulation of sheet stretch forming. In Numisheet 2005

Moreira LP, Ferron G (2004) Influence of the plasticity model in sheet metal forming simulations. J Mater Process Technol 155–156:1596–1603

Paul SP (1986) X-ray diffraction residual stress techniques. In: Mills K (ed) Metals handbook: ninth edition, Vol 10. American Society for Metals, Metals Park, pp 380–392

Wang L, Lee TC (2006) The effect of yield criteria on the forming limit curve prediction and the deep drawing process simulation. Int J Mach Tools Manuf 46:988–995

Withers PJ, Bhadeshia HKDH (2001) Overview residual stress Part 1 – Measurement techniques. Mater Sci Technol 17:355–365

Zhao L, Sowerby R, Sklad MP (1996) A theoretical and experimental investigation of limit strains in sheet metal forming. Int J Mech Sci 38:1307–1317

Acknowledgements

Authors would like to thank Dr.Balachandran of Advanced Engineering, Ashok Leyland for his suggestions and comments during the exercise and manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hariharan, K., Prakash, R.V., Sathya Prasad, M. et al. Evaluation of yield criteria for forming simulations based on residual stress measurement. Int J Mater Form 3, 291–297 (2010). https://doi.org/10.1007/s12289-010-0984-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-010-0984-9