Abstract

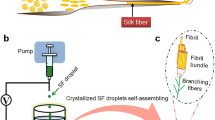

Silk fibroin with sophisticated hierarchical architectures from nano to macro scale shows excellent mechanical properties, good biocompatibility, and outstanding processability. In particular, the crystalline region in silk fibroin contributes high strength and toughness. However, it is difficult to obtain the crystalline silk nanofibrils or nanosheets through top-down methods. The existing silk-derived components are mainly amorphous and sacrifice the delicate structure of the pristine silk. Herein, we report a gentle method to extract the crystalline silk nanosheet (SNS) from the degummed silk fibers. The crystalline SNS has seven strands of β-sheet nanocrystal layer and shows a thickness of 2.75 nm. It can assemble into a membrane via a vacuum filtration process and shows high transparency, excellent thermal stability, outstanding cytocompatibility, and efficient dye interception. Moreover, without external stimuli, the crystalline SNS is capable of reversibly self-assembling to well-organized microfibers. The crystalline SNS is not only a new member of silk fibroin derivatives, but also a promising assemblable unit for versatile applications. We anticipate this work will provide a new insight into the construction and applications of diverse two-dimensional (2D) functional silk materials.

Similar content being viewed by others

Change history

07 July 2022

An Erratum to this paper has been published: https://doi.org/10.1007/s12274-022-4719-2

References

Tan, C. L.; Cao, X. H.; Wu, X. J.; He, Q. Y.; Yang, J.; Zhang, X.; Chen, J. Z.; Zhao, W.; Han, S. K.; Nam, G. H. et al. Recent advances in ultrathin two-dimensional nanomaterials. Chem. Rev. 2017, 117, 6225–6331.

Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F. M.; Sun, Z. Y.; De, S.; McGovern, I. T.; Holland, B.; Byrne, M.; Gun’Ko, Y. K. et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568.

Warner, J. H.; Rümmeli, M. H.; Bachmatiuk, A.; Büchner, B. Atomic resolution imaging and topography of boron nitride sheets produced by chemical exfoliation. ACS Nano 2010, 4, 1299–1304.

Naguib, M.; Mochalin, V. N.; Barsoum, M. W.; Gogotsi, Y. 25th anniversary article: MXenes: A new family of two-dimensional materials. Adv. Mater. 2014, 26, 992–1005.

Bang, G. S.; Nam, K. W.; Kim, J. Y.; Shin, J.; Choi, J. W.; Choi, S. Y. Effective liquid-phase exfoliation and sodium ion battery application of MOS2 nanosheets. ACS Appl. Mater. Interfaces 2014, 6, 7084–7089.

Coleman, J. N.; Lotya, M.; O’Neill, A.; Bergin, S. D.; King, P. J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R. J. et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 2011, 331, 568–571.

You, J.; Li, M. J.; Ding, B. B.; Wu, X. C.; Li, C. X. Crab chitin-based 2D soft nanomaterials for fully biobased electric devices. Adv. Mater. 2017, 29, 1606895.

Kim, U. J.; Park, J.; Kim, H. J.; Wada, M.; Kaplan, D. L. Three-dimensional aqueous-derived biomaterial scaffolds from silk fibroin. Biomaterials 2005, 26, 2775–2785.

Cheng, B. C.; Yan, Y. F.; Qi, J. J.; Deng, L. F.; Shao, Z. W.; Zhang, K. Q.; Li, B.; Sun, Z. L.; Li, X. M. Cooperative assembly of a peptide gelator and silk fibroin afford an injectable hydrogel for tissue engineering. ACS Appl. Mater. Interfaces 2018, 10, 12474–12484.

Lei, Z. Y.; Zhu, W. C.; Zhang, X. C.; Wang, X. J.; Wu, P. Y. Bio-inspired ionic skin for theranostics. Adv. Funct. Mater. 2021, 31, 2008020.

Zhang, F.; You, X. R.; Dou, H.; Liu, Z.; Zuo, B. Q.; Zhang, X. G. Facile fabrication of robust silk nanofibril films via direct dissolution of silk in CaCl2-formic acid solution. ACS Appl. Mater. Interfaces 2015, 7, 3352–3361.

Niu, Q. Q.; Peng, Q. F.; Lu, L.; Fan, S. N.; Shao, H. L.; Zhang, H. H.; Wu, R. L.; Hsiao, B. S.; Zhang, Y. P. Single molecular layer of silk nanoribbon as potential basic building block of silk materials. ACS Nano 2018, 12, 11860–11870.

Cai, J.; Zhang, L. N. Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol. Biosci. 2005, 5, 539–548.

Ling, S. J.; Li, C. M.; Jin, K.; Kaplan, D. L.; Buehler, M. J. Liquid exfoliated natural silk nanofibrils: Applications in optical and electrical devices. Adv. Mater. 2016, 28, 7783–7790.

Ling, S. J.; Qin, Z.; Li, C. M.; Huang, W. W.; Kaplan, D. L.; Buehler, M. J. Polymorphic regenerated silk fibers assembled through bioinspired spinning. Nat. Commun. 2017, 8, 1387.

Matsumoto, T.; Tatsumi, D.; Tamai, N.; Takaki, T. Solution properties of celluloses from different biological origins in LiCl·DMAc. Cellulose 2001, 8, 275–282.

Phillips, D. M.; Drummy, L. F.; Conrady, D. G.; Fox, D. M.; Naik, R. R.; Stone, M. O.; Trulove, P. C.; De Long, H. C.; Mantz, R. A. Dissolution and regeneration of Bombyx mori silk fibroin using ionic liquids. J. Am. Chem. Soc. 2004, 126, 14350–14351.

Yao, M.; Su, D. H.; Wang, W. Q.; Chen, X.; Shao, Z. Z. Fabrication of air-stable and conductive silk fibroin gels. ACS Appl. Mater. Interfaces 2018, 10, 38466–38475.

Dong, X. D.; Zhao, Q.; Xiao, L. Y.; Lu, Q.; Kaplan, D. L. Amorphous silk nanofiber solutions for fabricating silk-based functional materials. Biomacromolecules 2016, 17, 3000–3006.

Shao, Z. Z.; Vollrath, F. Surprising strength of silkworm silk. Nature 2002, 418, 741.

Yan, Y. F.; Cheng, B. C.; Chen, K. Z.; Cui, W. G.; Qi, J.; Li, X. M.; Deng, L. F. Enhanced osteogenesis of bone marrow-derived mesenchymal stem cells by a functionalized silk fibroin hydrogel for bone defect repair. Adv. Healthc. Mater. 2019, 8, 1801043.

Kundu, B.; Rajkhowa, R.; Kundu, S. C.; Wang, X. G. Silk fibroin biomaterials for tissue regenerations. Adv. Drug Deliv. Rev. 2013, 65, 457–470.

Tao, Y. Z.; Xu, W. L.; Yan, Y.; Cao, Y. Preparation and characterization of silk fibroin nanocrystals. Polym. Int. 2012, 61, 760–767.

Niu, Q. Q.; Huang, L.; Lv, S. S.; Shao, H. L.; Fan, S. N.; Zhang, Y. P. Pulse-driven bio-triboelectric nanogenerator based on silk nanoribbons. Nano Energy 2020, 74, 104837.

Shen, T. T.; Wang, T.; Cheng, G. T.; Huang, L.; Chen, L.; Wu, D. Y. Dissolution behavior of silk fibroin in a low concentration CaCl2-methanol solvent: From morphology to nanostructure. Int. J. Biol. Macromol. 2018, 113, 458–463.

Keten, S.; Xu, Z. P.; Ihle, B.; Buehler, M. J. Nanoconfinement controls stiffness, strength and mechanical toughness of β-sheet crystals in silk. Nat. Mater. 2010, 9, 359–367.

Zhou, L.; Chen, X.; Shao, Z. Z.; Huang, Y. F.; Knight, D. P. Effect of metallic ions on silk formation in the mulberry silkworm. Bombyxmori. J. Phys. Chem. B 2005, 109, 16937–16945.

Deligianni, D. D.; Katsala, N. D.; Koutsoukos, P. G.; Missirlis, Y. F. Effect of surface roughness of hydroxyapatite on human bone marrow cell adhesion, proliferation, differentiation and detachment strength. Biomaterials 2000, 22, 87–96.

Williams, R. J.; Smith, A. M.; Collins, R.; Hodson, N.; Das, A. K.; Ulijn, R. V. Enzyme-assisted self-assembly under thermodynamic control. Nat. Nanotechnol. 2009, 4, 19–24.

He, H. B.; Feng, M.; Chen, Q. D.; Zhang, X. Q.; Zhan, H. B. Light-induced reversible self-assembly of gold nanoparticles surface-immobilized with coumarin ligands. Angew. Chem., Int. Ed. 2016, 55, 936–940.

Liu, R. H.; Deng, Q. Q.; Yang, Z.; Yang, D. W.; Han, M. Y.; Liu, X. Y. “Nano-fishnet” structure making silk fibers tougher. Adv. Funct. Mater. 2016, 26, 5534–5541.

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Nos. 51973035 and 51733003).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Cheng, B., Lei, Z. & Wu, P. Bio-derived crystalline silk nanosheets for versatile macroscopic assemblies. Nano Res. 15, 5538–5544 (2022). https://doi.org/10.1007/s12274-022-4124-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-022-4124-x