Abstract

High-concentration oil mists can cause serious health problems to workers, which are generally mitigated by ventilation and purification systems. However, the coupling relationship between these systems is not clear. In this study, the effects of purifier outlet direction, purification air volume, installation height, and purification efficiency on indoor oil mist distribution were investigated by numerical simulation using an actual machining factory. The mitigation of oil mist in various combinations of ventilation and purification systems was also discussed. The results show that the outlet direction of the purifier has a great influence on the distribution of oil mist in the factory, and the maximum difference of oil mist concentration in the breathing zone under different orientations is 17%. The best purifier outlet direction is vertically upward. When the purifier outlet direction is upward, a larger purification air volume is beneficial for contaminant removal, and a lower purifier exhaust installation height is helpful for oil mist discharge from the bottom of the factory and reducing the concentration of oil mist in the breathing area. The oil mist concentration of purifier exhaust increases from 0 to 2 mg/m3 and the oil mist concentration in the breathing zone increases by 67%. The combined system of purification system with the roof exhaust system and displacement ventilation system has the optimal pollution removal efficiency and the lowest concentration of oil mist in the breathing zone compared to other systems. The research results can provide a reference for the design, installation, and operation of ventilation and purification systems in machining factories.

Similar content being viewed by others

References

Abdul-Wahab S, Fadlallah S, Al-Rashdi M (2018). Evaluation of the impact of ground-level concentrations of SO2, NOx, CO, and PM10 emitted from a steel melting plant on Muscat, Oman. Sustainable Cities and Society, 38: 675–683.

Bukowski JA (2003). Review of respiratory morbidity from occupational exposure to oil mists. Applied Occupational and Environmental Hygiene, 18: 828–837.

Cao G, Awbi H, Yao R, et al. (2014). A review of the performance of different ventilation and airflow distribution systems in buildings. Building and Environment, 73: 171–186.

Cao C, Gao J, Hou Y, et al. (2017). Ventilation strategy for random pollutant releasing from rubber vulcanization process. Indoor and Built Environment, 26: 248–255.

Cao S, Deng H, Zhou X, et al. (2019). Ventilation inlets design based on ventilation performance assessment using a dimensionless time scale. Indoor and Built Environment, 28: 1049–1063.

Cao Z, Zhai C, Wang Y, et al. (2020). Flow characteristics and pollutant removal effectiveness of multi-vortex ventilation in high pollution emission industrial plant with large aspect ratio. Sustainable Cities and Society, 54: 101990.

Cao Y, Wang Y, Yu Z, et al. (2022). Spatio-temporal distribution of gaseous pollutants from multiple sources in industrial buildings with different flow patterns. Building Simulation, 15: 1629–1644.

Chakroun W, Quadri M (2003). Flow characteristics of a local exhaust system. ASHRAE Transactions, 109(2): 527–599.

Chia TP, Ton SS, Liou SJ, et al. (2019). Effectiveness of engineering interventions in decreasing worker exposure to metalworking fluid aerosols. Science of the Total Environment, 659: 923–927.

EIA (2017). Manufacturing energy consumption survey 2014. U.S. Energy Information Administration.

Fan J-N, Yang Y, Wang Y, et al. (2022). Emission and local ventilation control of droplets generated by condensation and bubble-bursting during pickling. Sustainable Cities and Society, 76: 103491.

Feng Z, Long Z, Yu T (2016). Filtration characteristics of fibrous filter following an electrostatic precipitator. Journal of Electrostatics, 83: 52–62.

Gao R, Liu K, Li A, et al. (2018). Biomimetic duct tee for reducing the local resistance of a ventilation and air-conditioning system. Building and Environment, 129: 130–141.

Gao H, Long Z, Feng Z, et al. (2022). Numerical simulation of the characteristics of oil mist particles deposition in electrostatic precipitator. Process Safety and Environmental Protection, 164: 335–344.

Huang Y, Wang Y, Liu L, et al. (2015). Reduced-scale experimental investigation on ventilation performance of a local exhaust hood in an industrial plant. Building and Environment, 85: 94–103.

Huang Y, Wang Y, Ren X, et al. (2016). Ventilation guidelines for controlling smoke, dust, droplets and waste heat: Four representative case studies in Chinese industrial buildings. Energy and Buildings, 128: 834–844.

Huang Y, Lu K, Guo J, et al. (2020). Study on ventilation performance of lateral exhaust hood under the influence of two high-temperature buoyant jets. Building and Environment, 177: 106849.

Jaworek A, Sobczyk AT, Krupa A, et al. (2019). Hybrid electrostatic filtration systems for fly ash particles emission control. A review. Separation and Purification Technology, 213: 283–302.

Jiang D, Gao C, Liu L, et al. (2022). Application of nanoporous ceramic membrane derived from Fe/S/Si/Al/O-rich mining solid waste in oil–water separation and heavy metal removal of industrial high concentrated emulsifying wastewater. Separation and Purification Technology, 295: 121317.

Kermanizadeh A, Balharry D, Wallin H, et al. (2015). Nanomaterial translocation-the biokinetics, tissue accumulation, toxicity and fate of materials in secondary organs-a review. Critical Reviews in Toxicology, 45: 837–872.

Lacasse Y, Girard M, Cormier Y (2012). Recent advances in hypersensitivity pneumonitis. Chest, 142: 208–217.

Lau J, Chen Q (2006). Energy analysis for workshops with floor-supply displacement ventilation under the U.S. climates. Energy and Buildings, 38: 1212–1219.

Lau J, Chen Q (2007). Floor-supply displacement ventilation for workshops. Building and Environment, 42: 1718–1730.

Li S, Zhang S, Pan W, et al. (2019). Experimental and theoretical study of the collection efficiency of the two-stage electrostatic precipitator. Powder Technology, 356: 1–10.

Liu Y, Pan W, Long Z (2021). Optimization of air supply parameters for stratum ventilation based on proper orthogonal decomposition. Sustainable Cities and Society, 75: 103291.

Liu F, Zhang T, Yang L, et al. (2022). An improved wall-mounted displacement ventilation system in a large-span machining workshop. Building Simulation, 15: 1943–1953.

Long F, Liu J, Zheng L (2022). The effects of public environmental concern on urban-rural environmental inequality: Evidence from Chinese industrial enterprises. Sustainable Cities and Society, 80: 103787.

Long Z, Yao Q (2010). Evaluation of various particle charging models for simulating particle dynamics in electrostatic precipitators. Journal of Aerosol Science, 41: 702–718.

Long Z, Yao Q (2012). Numerical simulation of the flow and the collection mechanism inside a scale hybrid particulate collector. Powder Technology, 215–216: 26–37.

Mirer FE (2010). New evidence on the health hazards and control of metalworking fluids since completion of the OSHA advisory committee report. American Journal of Industrial Medicine, 53: 792–801.

NIOSH (1998). Criteria for a recommended standard occupational exposure to metalworking fluids. DHHS Publication No. 98-1002. Cincinnati, OH, USA: National Institute for Occupational Safety and Health.

Ren C, Haghighat F, Feng Z, et al. (2022). Impact of ionizers on prevention of airborne infection in classroom. Building Simulation, 16: 749–764.

Rim KT, Lim CH (2014). Biologically hazardous agents at work and efforts to protect workers’ health: a review of recent reports. Safety and Health at Work, 5: 43–52.

Thornburg J, Leith D (2000a). Size distribution of mist generated during metal machining. Applied Occupational and Environmental Hygiene, 15: 618–628.

Thornburg J, Leith D (2000b). Mist generation during metal machining. Journal of Tribology, 122: 544–549.

Tian E, Gao Y, Mo J (2019). Electrostatically assisted air coarse filtration for energy efficient ambient particles removal: Long-term performance in real environment and influencing factors. Building and Environment, 164: 106348.

Tong L, Gao J, Luo Z, et al. (2019). A novel flow-guide device for uniform exhaust in a central air exhaust ventilation system. Building and Environment, 149: 134–145.

Wang Y, Zou Y, Yang Y, et al. (2016). Movement and control of evaporating droplets released from an open surface tank in the push-pull ventilation system. Building Simulation, 9: 443–457.

Wang Y, Zhai C, Zhao T, et al. (2020). Numerical study on pollutant removal performance of vortex ventilation with different pollution source locations. Building Simulation, 13: 1373–1383.

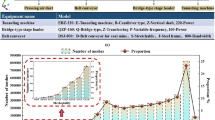

Wang Y, Murga A, Long Z, et al. (2021). Experimental study of oil mist characteristics generated from minimum quantity lubrication and flood cooling. Energy and Built Environment, 2: 45–55.

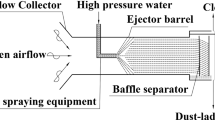

Wang Y, Long Z, Zhang H, et al. (2022a). Optimization study of sampling device for semi-volatile oil mist in the industrial workshop. Atmosphere, 13: 1048.

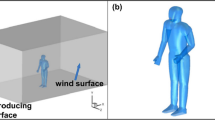

Wang Y, Shen X, Yoo S-J, et al. (2022b). Error analysis of human inhalation exposure simulation in industrial workshop. Building and Environment, 224: 109573.

Wei G, Chen B, Lai D, et al. (2020). An improved displacement ventilation system for a machining plant. Atmospheric Environment, 228: 117419.

Yang Y, Zhang Y, Liu F, et al. (2022). Distribution and removal efficiency of sulfuric droplets under two general ventilation modes. Building and Environment, 207: 108563.

Zhang Z, Chen Q (2007). Comparison of the Eulerian and Lagrangian methods for predicting particle transport in enclosed spaces. Atmospheric Environment, 41: 5236–5248.

Zhang Z, Balasubramanian R (2014). Physicochemical and toxicological characteristics of particulate matter emitted from a non-road diesel engine: comparative evaluation of biodiesel-diesel and butanol-diesel blends. Journal of Hazardous Materials, 264: 395–402.

Zhang J, Long Z, Liu W, et al. (2016a). Strategy for studying ventilation performance in factories. Aerosol and Air Quality Research, 16: 442–452.

Zhang J, Shao Y, Long Z (2016b). Physicochemical characterization of oily particles emitted from different machining processes. Journal of Aerosol Science, 96: 1–13.

Zhang S, Pan W, Zhang H, et al. (2020). High-efficient removal of airborne oil mist in a wire-plate electrostatic precipitator. Journal of Electrostatics, 108: 103516.

Acknowledgements

This work was supported by the National Nature Science Foundation of China (No. 51878442).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Yukun Wang, Yu Guo and Zhengwei Long. The first draft of the manuscript was written by Yukun Wang, Wei Liu, Zhengwei Long and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Wang, Y., Guo, Y., Hao, W. et al. Simulation study of the purification system for indoor oil mist control in machining factories. Build. Simul. 16, 1361–1374 (2023). https://doi.org/10.1007/s12273-023-1020-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12273-023-1020-6