Abstract

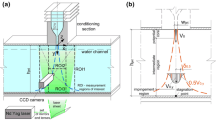

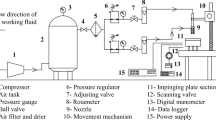

This paper presents a numerical study on the required momentum flux ratio to prevent air curtain breakthrough in case of cross-curtain (i.e. cross-jet) pressure gradients. 2D steady Reynolds-averaged Navier-Stokes (RANS) CFD simulations with the RNG k-ε turbulence model are employed for jet Reynolds numbers ranging from 5,000 to 30,000. First, the computational model is validated based on particle image velocimetry (PIV) measurements. Second, the influence of several jet parameters on the separation efficiency is evaluated for a moderate cross-jet pressure difference of 10 Pa. These are the ratio of the jet discharge momentum flux to the jet cross-flow momentum flux (momentum flux ratio), the jet height-to-width ratio and the jet discharge angle. Finally, the minimum deflection modulus to prevent jet breakthrough and the corresponding momentum flux ratio by an analytical equation and by CFD are compared. The results show that, for the configuration under study: (1) jets with the smallest height-to-width ratios (β = 18) provide the highest separation efficiency; (2) inclined jets with discharge angles α0 = 5° and 10° provide slightly higher separation efficiency than straight jets (α0 = 0°) and jets with α0 = 20°; (3) the maximum modified separation efficiency is reached at lower momentum flux ratios for jets with smaller height-to-width ratios and for inclined jets; (4) the analytical and CFD values of the optimal momentum flux ratio differ with up to 31.2%. This study shows how the separation efficiency of air curtains can be improved by adjusting certain jet parameters.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Abbreviations

- d jet :

-

nozzle depth [m]

- D :

-

depth [m]

- D m :

-

deflection modulus [—]

- D m,min :

-

minimum deflection modulus [—]

- D s :

-

diameter of PIV seeding particles [m]

- f middle :

-

solution for mean velocity obtained on the middle grid [m/s] solution for turbulent kinetic energy obtained on the middle grid [m2/s2]

- f coarse :

-

solution for mean velocity obtained on the coarse grid [m/s] solution for turbulent kinetic energy obtained on the coarse grid [m2/s2]

- FAC1.1:

-

factor of 1.1 of the observations [—]

- FAC1.5:

-

factor of 1.5 of the observations [—]

- F S :

-

safety factor used for grid convergence index [—]

- g :

-

gravitational acceleration [m/s2]

- h c :

-

height of contraction [m]

- h jet :

-

jet height [m]

- H :

-

height [m]

- H d :

-

doorway height [m]

- k :

-

turbulent kinetic energy [m2/s2]

- L :

-

length [m]

- M cf :

-

cross-flow momentum flux [kg/s2]

- M jet :

-

jet discharge momentum flux [kg/s2]

- M jet,min :

-

jet discharge momentum flux corresponding to Dm,min [kg/s2]

- M jet,sf :

-

jet discharge momentum flux Mjet,min corrected by a safety factor of 2 [kg/s2]

- n :

-

number of data points [—]

- n→i :

-

outward normal vector [—]

- O i :

-

time-averaged values of mean velocity obtained from PIV experiments (observations) [m/s] time-averaged values of turbulent kinetic energy obtained from PIV experiments (observations) [m2/s2]

- ΔP :

-

cross-jet static pressure gradient [Pa]

- P i :

-

time-averaged values (predictions) of mean velocity obtained from CFD simulations [m/s] time-averaged values (predictions) of turbulent kinetic energy obtained from CFD simulations [m2/s2]

- P l :

-

mean static pressure in left side of enclosure [Pa]

- P r :

-

mean static pressure in right side of enclosure [Pa]

- Q 0 :

-

heat or pollutant mass transfer rate by transport of outdoor air through the opening to the indoor environment without AC in operation (infiltration) [kg/s]

- Q*0 :

-

heat or mass transfer rate by transport of indoor air through the opening to the outdoor environment (exfiltration) without AC in operation [kg/s]

- Q ac :

-

heat or pollutant mass transfer rate by transport of outdoor air through the opening to the indoor environment (infiltration) with AC in operation [kg/s]

- Q*ac :

-

heat or mass transfer rate by transport of indoor air through the opening to the outdoor environment (exfiltration) and by transport of air originating from the AC to the outdoor environment with AC in operation [kg/s]

- p :

-

formal order of accuracy used for grid convergence index [—]

- r :

-

linear grid refinement factor for grid sensitivity analysis [—]

- Re :

-

Reynolds number [—]

- Re y :

-

wall-distance-based Reynolds number [—]

- Sc t :

-

turbulent Schmidt number [—]

- U :

-

mean lateral (x-direction) velocity component [m/s]

- U cf :

-

the average velocity of the cross-flow through the enclosure created by the pressure gradient for the case without AC in operation [m/s]

- |V| :

-

mean velocity magnitude [m/s]

- V→:

-

mean velocity vector [m/s]

- |V0|:

-

mean jet velocity magnitude at the nozzle exit [m/s]

- V :

-

mean streamwise (y-direction) velocity component [m/s]

- V 0 :

-

mean streamwise jet velocity at the nozzle exit [m/s]

- w jet :

-

jet width at the nozzle exit [m]

- w jet ′ :

-

jet width downstream the nozzle exit at y = hjet [m]

- x :

-

Cartesian coordinate [m]

- y :

-

Cartesian coordinate [m]

- y*:

-

dimensionless wall distance [—]

- Y cl :

-

clean water mass fraction [—]

- Y pol :

-

pollutant mass fraction [—]

- α :

-

angle of the jet centerline downstream of the nozzle exit at y = hjet [°]

- α 0 :

-

jet discharge angle [°]

- β :

-

jet height-to-width ratio [—]

- γ :

-

momentum flux ratio [—]

- γ CFD :

-

optimal momentum flux ratio as obtained from the CFD simulations [—]

- γ min :

-

minimum momentum flux ratio as obtained from the analytical equation [—]

- γ sf :

-

momentum flux ratio as obtained from the analytical equation and corrected by a safety factor [—]

- δγ :

-

relative difference between momentum flux ratios [—]

- ε :

-

turbulence dissipation rate [m2/s3]

- η :

-

separation efficiency [—]

- η*:

-

modified separation efficiency [—]

- ρ :

-

fluid density [kg/m3]

- ρ i :

-

density of indoor air [kg/m3]

- ρ o :

-

density of outdoor air [kg/m3]

- ρs:

-

density of the PIV seeding particles [kg/m3]

- ρ w :

-

density of water [kg/m3]

- ν :

-

kinematic viscosity [m2/s]

- 2D:

-

two-dimensional

- 3D:

-

three-dimensional

- AC:

-

air curtain

- AR:

-

aspect ratio, i.e. the ratio of nozzle depth djet to width wjet

- CFD:

-

computational fluid dynamics

- GCI:

-

grid convergence index

- LES:

-

large eddy simulation

- LRNM:

-

low-Reynolds number modeling

- PIV:

-

particle image velocimetry

- PTIJ:

-

plane turbulent impinging jet

- RANS:

-

Reynolds-averaged Navier-Stokes

- RNG:

-

renormalization group k-ε turbulence model

References

Alanis Ruiz C, van Hooff T, Blocken B, Heijst GJF (2018). CFD analysis of the effect of pressure gradients on the separation efficiency of a generic air curtain. In: Proceedings of Roomvent&Ventilation (REHVA 2018), Helsinki, Finland, pp. 241–246.

ANSYS (2013). ANSYS Fluent 15.0. User’s Guide. ANSYS Inc.

Van Belleghem M, Verhaeghe G, T’Joen C, Huisseune H, De Jaeger P, De Paepe M (2012). Heat transfer through vertically downwardblowing single-jet air curtains for cold rooms. Heat Transfer Engineering, 33: 1196–1206.

Blocken B (2015). Computational Fluid Dynamics for urban physics: Importance, scales, possibilities, limitations and ten tips and tricks towards accurate and reliable simulations. Building and Environment, 91: 219–245.

Blocken B (2018). LES over RANS in building simulation for outdoor and indoor applications: a foregone conclusion? Building Simulation, 11: 821–870.

Casey M, Wintergerste T (2000). ERCOFTAC best practice guidelines: ERCOFTAC special interest group on “quality and trust in industrial CFD” (Version 1). European Research Community on Flow, Turbulence and Combustion.

Chen J-K, Huang RF, Hung W-L (2013). Flow and leakage characteristics of a sashless inclined air-curtain (sIAC) fume hood containing tall pollutant-generation tanks. Journal of Occupational and Environmental Hygiene, 10: 694–704.

Costa JJ, Oliveira LA, Silva MCG (2006). Energy savings by aerodynamic sealing with a downward-blowing plane air curtain—A numerical approach. Energy and Buildings, 38: 1182–1193.

Craft TJ, Graham LJW, Launder BE (1993). Impinging jet studies for turbulence model assessment—II. An examination of the performance of four turbulence models. International Journal of Heat and Mass Transfer, 36: 2685–2697.

Deo RC, Mi J, Nathan GJ (2007a). The influence of nozzle-exit geometric profile on statistical properties of a turbulent plane jet. Experimental Thermal and Fluid Science, 32: 545–559.

Deo RC, Mi J, Nathan GJ (2007b). The influence of nozzle aspect ratio on plane jets. Experimental Thermal and Fluid Science, 31: 825–838.

Dutta R, Dewan A, Srinivasan B (2013). Comparison of various integration to wall (ITW) RANS models for predicting turbulent slot jet impingement heat transfer. International Journal of Heat and Mass Transfer, 65: 750–764.

Foster AM, Swain MJ, Barrett R, D’Agaro P, James SJ (2006). Effectiveness and optimum jet velocity for a plane jet air curtain used to restrict cold room infiltration. International Journal of Refrigeration, 29: 692–699.

Frank D, Linden PF (2014). The effectiveness of an air curtain in the doorway of a ventilated building. Journal of Fluid Mechanics, 756: 130–164.

Frank D, Linden PF (2015). The effects of an opposing buoyancy force on the performance of an air curtain in the doorway of a building. Energy and Buildings, 96: 20–29.

Gonçalves JC, Costa JJ, Lopes AMG (2019). Parametric study on the performance of an air curtain based on CFD simulations - New proposal for automatic operation. Journal of Wind Engineering and Industrial Aerodynamics, 193: 103951.

Goubran S, Qi D, Saleh WF, Wang LL, Zmeureanu R (2016). Experimental study on the flow characteristics of air curtains at building entrances. Building and Environment, 105: 225–235.

Hayes FC, Stoecker WF (1969a). Heat transfer characteristics of the air curtain. ASHRAE Transactions, 75@@(2): 153–167.

Hayes FC, Stoecker WF (1969b). Design data for air curtains. ASHRAE Transactions, 75@@(2): 168–180.

Howell RH, Shibata M (1980). Optimum heat transfer through turbulent recirculated plane air curtains. ASHRAE Transactions, 86@@(1): 188–200.

Isman MK, Pulat E, Etemoglu AB, Can M (2008). Numerical investigation of turbulent impinging jet cooling of a constant heat flux surface. Numerical Heat Transfer, Part A: Applications, 53: 1109–1132.

Jaramillo JE, Perez-Segarra CD, Rodriguez I, Oliva A (2008). Numerical study of plane and round impinging jets using RANS models. Numerical Heat Transfer, Part B: Fundamentals, 54: 213–237.

Khayrullina A, van Hooff T, Blocken B, van Heijst GJF (2017). PIV measurements of isothermal plane turbulent impinging jets at moderate Reynolds numbers. Experiments in Fluids, 58: 31.

Khayrullina A, van Hooff T, Blocken B, van Heijst G (2019). Validation of steady RANS modelling of isothermal plane turbulent impinging jets at moderate Reynolds numbers. European Journal of Mechanics, B/Fluids, 75: 228–243.

Koseoglu MF, Baskaya S (2010). The role of jet inlet geometry in impinging jet heat transfer, modeling and experiments. International Journal of Thermal Sciences, 49: 1417–1426.

Moureh J, Yataghene M (2016). Numerical and experimental study of airflow patterns and global exchanges through an air curtain subjected to external lateral flow. Experimental Thermal and Fluid Science, 74: 308–323.

Nielsen PV, Allard F, Awbi HB, Davidson L, Schalin A (2007). Computational fluid dynamics in ventilation design REHVA guidebook No 10. International Journal of Ventilation, 6: 291–294.

Nino E, Fasanella R, Di Tommaso RM (2011). Submerged rectangular air jets as a particulate barrier. Building and Environment, 46: 2375–2386.

Park TH, Choi HG, Yoo JY, Kim SJ (2003). Streamline upwind numerical simulation of two-dimensional confined impinging slot jets. International Journal of Heat and Mass Transfer, 46: 251–262.

Rajaratnam N (1976). Turbulent Jets. New York: Elsevier Scientific.

Rhea S, Bini M, Fairweather M, Jones WP (2009). RANS modelling and LES of a single-phase, impinging plane jet. Computers & Chemical Engineering, 33: 1344–1353.

Roache PJ (1994). Perspective: A method for uniform reporting of grid refinement studies. Journal of Fluids Engineering, 116: 405–413.

Roache PJ (1997). Quantification of uncertainty in computational fluid dynamics. Annual Review of Fluid Mechanics, 29: 123–160.

Schatzmann M, Olesen H, Franke J (2010). COST 732 Model Evaluation Case Studies: Approach and Results, COST Action.

Sharif MAR, Mothe KK (2009). Evaluation of turbulence models in the prediction of heat transfer due to slot jet impingement on plane and concave surfaces. Numerical Heat Transfer, Part B: Fundamentals, 55: 273–294.

Shih Y-C, Yang A-S, Lu C-W (2011). Using air curtain to control pollutant spreading for emergency management in a cleanroom. Building and Environment, 46: 1104–1114.

Sirén K (2003). Technical dimensioning of a vertically upwards blowing air curtain—part I. Energy and Buildings, 35: 681–695.

Tominaga Y, Stathopoulos T (2007). Turbulent Schmidt numbers for CFD analysis with various types of flowfield. Atmospheric Environment, 41: 8091–8099.

Valkeapää A, Sirén K, Raappana I (2006). Air leakage through horizontal air curtains—An experimental study. In: Proceedings of the 8th International conference (VENT 2006). Chicago, USA.

Wang LL, Zhong Z (2014). An approach to determine infiltration characteristics of building entrance equipped with air curtains. Energy and Buildings, 75: 312–320.

Wolfshtein M (1969). The velocity and temperature distribution in one-dimensional flow with turbulence augmentation and pressure gradient. International Journal of Heat and Mass Transfer, 12: 301–318.

Yakhot V, Orszag SA, Thangam S, Gatski TB, Speziale CG (1992). Development of turbulence models for shear flows by a double expansion technique. Physics of Fluids A: Fluid Dynamics, 4: 1510–1520.

Yang S, Alrawashdeh H, Zhang C, Qi D, Wang LL, Stathopoulos T (2019). Wind effects on air curtain performance at building entrances. Building and Environment, 151: 75–87.

Zhai ZJ, Osborne AL (2013). Simulation-based feasibility study of improved air conditioning systems for hospital operating room. Frontiers of Architectural Research, 2: 468–475.

Acknowledgements

Twan van Hooff is currently a postdoctoral fellow of the Research Foundation–Flanders (FWO) and acknowledges its financial support (project FWO 12R9718N). The authors acknowledge the partnership with ANSYS CFD.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access: This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Khayrullina, A., van Hooff, T., Alanis Ruiz, C. et al. Minimum momentum flux ratio required to prevent air curtain breakthrough in case of cross-curtain pressure gradients: CFD versus analytical equation. Build. Simul. 13, 943–960 (2020). https://doi.org/10.1007/s12273-020-0633-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12273-020-0633-2