Abstract

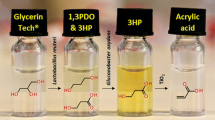

Discharging the unrefined glycerine, a by-product from biodiesel production is the simplistic solution adopted for its management which has led to its price reduction in the market worldwide and created serious environmental impact. Therefore, we have explored the application of unrefined glycerine pitch as direct fermentative substrate in the biosynthesis of novel yellow-pigmented poly(3-hydroxybutyrate-co-4-hydroxybutyrate) [P(3HB-co-4HB)] copolymer by Cupriavidus sp. USMAHM13 through onestage cultivation. Utilization of glycerine pitch (10 g/L) together with 1,4-butanediol (5 g/L) had resulted in the highest achievement of 2.91 g/L of P(3HB-co-40%4HB) copolymer which was naturally dyed with the yellow pigment through the co-extraction process. Enhancement of 4HB monomer accumulation was also attained through the addition of ammonium acetate as nitrogen source. It was revealed that utilization of recovered crude glycerine from glycerine pitch was more preferred compared to the other recovered components. Utilization of glycerine pitch in the biosynthesis of P(3HB-co-4HB) copolymer would not only contribute to the efficient waste management but also would promote the development of cost-efficiency microbial fermentation.

Similar content being viewed by others

References

Hazimah, A. H., T. L. Ooi, and A. Salmiah (2003) Recovery of glycerol and diglycerol from glycerol pitch. J. Oil Palm Res. 15: 1–5.

Hidawati, E. N. and A. M. M. Sakinah (2011) Treatment of glycerine pitch from biodiesel production. Int. J. Chem. Environ. Eng. 2: 309–313.

Yang, F., M. A. Hanna, and R. Sun (2012) Value-added uses for crude glycerol-a by-product of biodiesel production. Biotechnol. Biofuels 5: 13–22.

Leoneti, A. B., V. Aragão-Leoneti, and S. V. W. B. de Oliveira (2012) Glycerol as a by-product of biodiesel production in Brazil: Alternatives for the use of unrefined glycerol. Renew. Energ. 45: 138–145.

Akaraonye, E., T. Keshavarz, and I. Roy (2010) Production of polyhydroxyalkanoates: The future green materials of choice. J. Chem. Technol. Biotechnol. 85: 732–743.

Chen, G.-Q. (2009) A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem. Soc. Rev. 38: 2434–2446.

Koller, M., I. Gasser, F. Schmid, and G. Berg (2011) Linking ecology with economy: Insights into polyhydroxyalkanoate-producing microorganisms. Eng. Life. Sci. 11: 222–237.

Amara, A. A. (2008) Polyhydroxyalkanoates: From basic research and molecular biology to application. IIUM Eng. J. 9: 37–73.

Williams, S. F. and D. P. Martin (2002) Applications of PHAs in medicine and pharmacy. pp. 91–128. In: Y. Doi, and A. Steinbüchel (eds). Biopolymers: Polyesters. Wiley-VCH, Weinhem, Germany.

Cavalheiro, J. M. B. T., R. S. Raposo, M. C. M. D. de Almeida, M. T. Cesário, C. Sevrin, C. Grandfils, and M. M. R. da Fonseca (2012) Effect of cultivation parameters on the production of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-4-hydroxybutyrate-3-hydroxyvalerate) by Cupriavidus necator using waste glycerol. Bioresour. Technol. 111: 391–397.

Ashby, R. D., D. K. Y. Solaiman, and T. A. Foglia (2004) Bacterial poly(hydroxyalkanoate) polymer production from the biodiesel co-product stream. J. Polym. Environ. 12: 105–112.

Ramachandran, H. and A. A. Amirul (2013) Yellow-pigmented Cupriavidus sp., a novel bacterium capable of utilizing glycerine pitch for the sustainable production of P(3HB-co-4HB). J. Chem. Technol. Biotechnol. 88: 1030–1038.

Braunegg, G., B. Sonnleitner, and R. M. Laffer (1978) A rapid gas chromatographic method for the determination of poly-â-hydroxyalkanoates acid in microbial biomass. Eur. J. Appl. Microbiol. Biotechnol. 6: 29–37.

Saranya, V. and R. Shenbagarathai (2010) Effect of nitrogen and calcium sources on growth and production of PHA of Pseudomonas sp. LDC-5 and its mutant. Curr. Res. J. Biol. Sci. 2: 164–167.

Lee, Y. H., M. S. Kang, and Y. M. Jung (2000) Regulating the molar fraction of 4-hydroxybutyrate in poly(3-hydroxybutyrate-4-hydroxybutyrate) biosynthesis by Ralstonia eutropha using propionate as a stimulator. J. Biosci. Bioeng. 89: 380–383.

Chanprateep, S., Y. Katakura, S. Visetkoop, H. Shimizu, S. Kulpreecha, and S. Shioya (2008) Characterization of newly isolated Ralstonia eutropha strain A-04 and kinetic study of biodegradable copolyester poly(3-hydroxybutyrate-co-4-hydroxybutyrate) production. J. Ind. Microbiol. Biotechnol. 35: 1205–1215.

Blundell, M. R. and D. G. Wild (1969) Inhibition of bacterial growth by metal salts. Biochem. J. 115: 207–212.

Chanprateep, S., K. Buasri, A. Muangwong, and P. Utiswannakul (2010) Biosynthesis and biocompatibility of biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate). Polym. Degrad. Stabil. 95: 2003–2012.

Irwin, R. D. (1996) National toxicology program summary report on the metabolism, disposition, and toxicity of 1,4-butanediol. National Institutes of Health, USA.

Lee, S. E., Q. X. Li, and J. Yu (2009) Diverse protein regulations on PHA formation in Ralstonia eutropha on short chain organic acids. Int. J. Biol. Sci. 5: 215–225.

Tanadchangsaeng, N. and J. Yu (2012) Microbial synthesis of polyhydroxybutyrate from glycerol: Gluconeogenesis, molecular weight and material properties of biopolyester. Biotechnol. Bioeng. 109: 2808–2818.

Teeka, J., T. Imai, X. Cheng, A. Reungsang, T. Higuchi, K. Yamamoto, and M. Sekine (2010) Screening of PHA-producing bacteria using biodiesel derived waste glycerol as a sole carbon source. J. Water Environ. Technol. 8: 373–381.

Sangkharak, K. and P. Prasertsan (2011) Utilization of biodiesel waste as a feedstock for the production of polyhydroxybutyrate by Cupriavidus necator. Afr. J. Biotechnol. 10: 17812–17824.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramachandran, H., Amirul, A.A. Evaluation of unrefined glycerine pitch as an efficient renewable carbon resource for the biosynthesis of novel yellow-pigmented P(3HB-co-4HB) copolymer towards green technology. Biotechnol Bioproc E 18, 1250–1257 (2013). https://doi.org/10.1007/s12257-013-0452-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-013-0452-8