Abstract

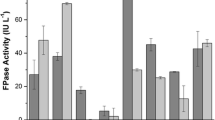

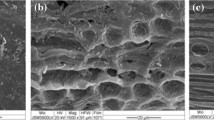

Palm kernel cake (PKC), is an agro-industrial residue created in the palm oil industry, and large quantities of PKC are produced in Malaysia. Sustainable development of the palm oil industry in Malaysia demands an economical technology for the environmentally friendly utilization of PKC in industrial utility systems. This research was carried out to evaluate the use of PKC in the production of cellulase by the cultivation of Aspergillus niger FTCC 5003 in a laboratory packed-bed bioreactor for seven days. A central composite design was used to perform eighteen trials of solid substrate fermentation under selected conditions of incubation temperature, initial moisture content of substrate, and airflow rate. Experimental results showed that a cellulase yield of 244.53 U/g of dry PKC was obtained when 100 g of PKC was hydrolyzed at an incubation temperature of 32.5°C, an initial moisture level of 60%, and an aeration rate of 1.5 L/min/g PKC. An empirical second-order polynomial model was adjusted to the experimental data to evaluate the effects of the studied operating variables on cellulase production. The statistical model revealed that the quadratic term for initial moisture content had a significant effect on the production of cellulase (P < 0.01). The regression model also indicated that the quadratic terms for incubation temperature and interaction effects between initial moisture content and aeration rate significantly influenced cellulase production (P < 0.05). The empirical model determined that the optimum conditions for cellulase production were an incubation temperature of 31.0°C, an initial moisture content of 59.0% and an airflow rate of 1.55 L/min/g PKC.

Similar content being viewed by others

References

Wu, X., J. McLaren, R. Madl, and D. Wang (2010) Biofuels from lignocellulosic biomass. pp. 19–41. In: O. V. Singh and S. P. Harvey (eds.). Sustainable biotechnology. Springer, The Netherland.

Malaysian Palm Oil Board (MPOB), Economics & Industry Development Division. http://econ.mpob.gov.my/economy/Overview_2009.pdf

Wu, T. Y., A. Mohammad, J. Md. Jahim, and N. Anuar (2009) A holistic approach to managing palm oil mill effluent (POME): Biotechnological advances in the sustainable reuse of POME. Biotechnol. Adv. 27: 40–52.

Sohail, M., R. Siddiqi, A. Ahmad, and S. Ahmad-khan (2009) Cellulase production from Aspergillus niger MS82: Effect of temperature and pH. New Biotechnol. 25: 437–441.

Pandey, A., C. R. Soccol, J. A. Rodriguez-Leon, and P. Nigam (2001) Solid-state fermentation in biotechnology. 1st ed., pp. 17–27. Asiatech Publishers Inc (API), New Delhi, India.

Lakshmi, G. S., C. S. Raoa, R. S. Raob, P. J. Hobbsb, and R. S. Prakasham (2009) Enhanced production of xylanase by a newly isolated Aspergillus terreus under solid state fermentation using palm industrial waste: A statistical optimization. Biochem. Engin. J. 48: 51–57.

Kalogeris, E., F. Iniotaki, E. Topakas, P. Christakopoulos, D. Kekos, and B. J. Macris (2003) Performance of an intermittent agitation rotating drum type bioreactor for solid-state fermentation of wheat straw. Bioresour. Technol. 86: 207–213.

Li, X. and R. Jia (2008) Decolorization and biosorption for Congo red by system rice hull-Schizophyllum sp. F17 under solid-state condition in a continuous flow packed-bed bioreactor. Bioresour. Technol. 99: 6885–6892.

Ong, L. G. A., S. Abd-Aziz, S. Noraini, M. I. A. Karim, and M. A. Hassan (2004) Enzyme production and profile by Aspergillus niger during solid substrate fermentation using palm kernel cake as substrate. Appl. Biochem. Biotechnol. 118: 73–79.

Sternberg, D. (1976) Production of cellulase by Trichoderma. Biotechnol. Bioeng. Symp. 6: 35–53.

Haaland, P. D. (1989) Experimental design in biotechnology. 1st ed., CRC press, NY, USA.

Ghose, T. K. (1987) Measurement of cellulase activities. Pure Appl. Chem. 59: 257–268.

Miller, G. L. (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal. Chem. 31: 426–428.

Lowry, O. H., N. J. Rosebrough, A. L. Farr, and R. J. Randall (1951) Protein measurement with the folin phenol reagent. J. Biol. Chem. 193: 265–275.

Lonsane, B. K., N. P. Ghildyal, S. Budiatman, and S. V. Ramakrishna (1985) Engineering aspects of solid-state fermentation. Enzym. Microb. Technol. 7: 258–265.

Patil, S. R. and A. Dayanand (2006) Optimization of process for the production of fungal pectinases from deseeded sunflower head in submerged and solid-state conditions. Bioresour. Technol. 97: 2340–2344.

Wang, X. J., J. G. Bai, and Y. X. Liang (2006) Optimization of multienzyme production by two mixed strains in solid-state fermentation. Appl. Microbiol. Biotechnol. 73: 533–540.

Jecu, L. (2000) Solid state fermentation of agricultural wastes for endoglucanase production. Ind. Crops Prod. 11: 1–5.

Gokhale, D. V., S. G. Patil, and K. B. Bastawed (1991) Optimization of cellulase production by Aspergilluls niger NCIM 1207. Appl. Biochem. Biotechnol. 30: 99–109.

Venkateswarlu, G., P. S. M. Krishna, A. Pandey, and L. V. Rao (2000) Evaluation of Amycolatopsis mediterranei VA18 for production of rifamycin-B. Proc. Biochem. 36: 305–309.

Prior, B. A., J. C. D. Preez, and P. W. Rein (1992) Environmental parameters. pp. 65–85. In: H. W. Doelle, D. A. Mitchell, and C. E. Rolz (eds.). Solid substrate cultivation. Elsevier, UK.

Gao, J., H. Weng, D. Zhu, M. Yuan, F. Guan, and Y. Xi (2008) Production and characterization of cellulolytic enzymes from the thermoacidophilic fungal Aspergillus terreus M11 under solidstate cultivation of corn stover. Bioresour. Technol. 99: 7623–7629.

Kumar, S. and T. Satyanarayana (2004) Statistical optimization of a thermostable and neutral glucoamylase production by a thermophilic mold Thermomucor indicae-seudaticae in solid-state fermentation. World J. Microbiol. Biotechnol. 20: 895–902.

Milagres, A. M. F., E. Santos, T. Piovan, and I. C. Roberto (2004) Production of xylanase by Thermoascus aurantiacus from sugar cane bagasse in an aerated growth fermentor. Proc. Biochem. 39: 1387–1391.

Shojaosadati, S. A. and V. Babaeipour (2002) Citric acid production from apple pomace in multi-layer packed bed solid-state bioreactor. Proc. Biochem. 37: 909–914.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdeshahian, P., Samat, N., Hamid, A.A. et al. Solid substrate fermentation for cellulase production using palm kernel cake as a renewable lignocellulosic source in packed-bed bioreactor. Biotechnol Bioproc E 16, 238–244 (2011). https://doi.org/10.1007/s12257-010-0320-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-010-0320-8