Abstract

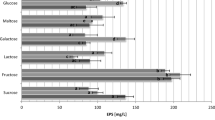

Rhizopus oryzae RUR709 mutant was isolated based on halo size from selection medium via mutagenesis with UV and γ-rays, and the production of fumaric acid in the submerged fermentation was assessed. The maximum concentration of fumaric acid was obtained using 0.5% corn steep liquor (CSL) as the nitrogen source. Organic nitrogen sources were shown to be more effective in fumaric acid production than inorganic nitrogen sources. Using optimum medium obtained by response surface methodology (RSM), the maximum concentration of fumaric acid achieved in flask culture was 26.2 g/L, which is fairly close to the 27.4 g/L predicted by the model. The highest concentration of fumaric acid in the stirred-tank reactor generated by the R. oryzae RUR709 mutant was 32.1 g/L and yield (0.45 g/g) and productivity (0.32 g/L/h) were highest at 4 days.

Similar content being viewed by others

References

Lee, S. Y., S. H. Hong, S. H. Lee, and S. J. Park (2004) Fermentative production of chemicals that can be used for polymer synthesis. Macromol. Biosci. 4: 157–164.

Roa Engel, C. A., A. J. J. Straathof, T. W. Zijlmans, W. M. van Gulik, and L. A. M. van der Wielen (2008) Fumaric acid production by fermentation. Appl. Microbiol. Biotechnol. 78: 379–389.

Robinson, W. D. and R. A. Mount (1981) Maleic anhydride, maleic acid and fumaric acid. pp. 770–793. In: M. Grayson and D. Eckroth (eds.). Kirk-Othmer Encyclopedia of Chemical Technology. 3rd ed, vol. 14. Wiley, NY, USA.

Magnuson, J. K. and L. L. Lasure (2004) Organic acid production by filamentous fungi. pp. 307–340. In: J. S. Tracz and L. Lange (eds.). Advances in fungal biotechnology for industry, agriculture and medicine. Kluwer/Plenum, NY, USA.

Goldberg, I., J. S. Rokem, and O. Pines (2006) Organic acids: Old metabolites, new themes. J. Chem. Technol. Biotechnol. 81: 1601–111.

Foster, J. W. and S. A. Waksman (1939) The production of fumaric acid by molds belonging to the genus Rhizopus. J. Am. Chem. Soc. 61: 127–135.

Kenealy, W., E. Zaady, J. C. DuPreez, B. Stieglitz, and I. Goldberg (1986) Biochemical aspects of fumaric acid accumulation by Rhizopus arrhizus. Appl. Environ. Microbiol. 52: 128–133.

Carta, F. S., C. R. Soccol, L. P. Ramos, and J. D. Fontana (1999) Production of fumaric acid by fermentation of enzymatic hydrolysates derived from cassava bagasse. Bioresour. Technol. 68: 23–28.

Zhou, Y., J. Du, and G. T. Tsao (2002) Comparison of fumaric acid production by Rhizopus oryzae using different neutralizing agents. Biopro. Biosyst. Eng. 25: 179–181.

Federici, F., M. Moresi, E. Parente, M. Petruccioli, and P. Piccioni (1993) Effect of stirring rate and neutralizing agent on fumaric acid production by Rhizopus arrhizus. Ital. J. Food Sci. 4: 387–396.

Du, J., N. Cao, C. Gong, G. Tsao, and N. Yuan (1997) Fumaric acid production in airlift loop reactor with porous sparger. Appl. Biochem. Biotechnol. 63: 541–556.

Kautola, H. and Y. Y. Linko (1989) Fumaric acid production from xylose by immobilized Rhizopus arrhizus cells. Appl. Microbiol. Biotechnol. 31: 448–452.

Petruccioli, M. and E. Angiani (1995) Fumaric acid production by Rhizopus arrhizus immobilized in different carriers. Ann. Microbiol. Enzimol. 45: 119–128.

Cao, N., J. Du, C. Chen, C. S. Gong, and G. T. Tsao (1997) Production of fumaric acid by immobilized Rhizopus using rotary biofilm contactor. Appl. Biochem. Biotechnol. 63–65: 387–394.

Shi, F., Z. Xu, and P. Cen (2006) Optimization of -polyglutamic acid production by Bacillus subtilis ZJU-7 using a surfaceresponse methodology. Biotechnol. Bioproc. Eng. 11: 251–257.

Vázquez, M. and A. M. Martin (1998) Optimization of Phaffia rhodozyma continuous culture through response surface methodology. Biotechnol. Bioeng. 57: 314–320.

Wasli, A. S., M. M. Salleh, S. Abd-Aziz, O. Hassan, and N. M. Mahadi (2009) Medium optimization for chitinase production from Trichoderma virens using central composite design. Biotechnol. Bioproc. Eng. 14: 781–787.

Park, Y. S., S. W. Kang, J. S. Lee, S. I. Hong, and S. W. Kim (2002) Xylanase production in solid state fermentation by Aspergillus niger mutant using statistical experimental designs. Appl. Microbiol. Biotechnol. 58: 761–766.

Montgomery, D. C. (1991) Response surface methods and designs. pp. 521–568. In: D. C. Montgomery (ed.). Design and analysis of experiments. John Wiley & Sons, NY, USA.

Moresi, M., E. Parente, M. Petruccioli, and F. Federici (1991) Optimization of fumaric acid production from potato flour by Rhizopus arrhizus. Appl. Microbiol. Biotechnol. 36: 35–39.

Riscaldati, E., M. Moresi, F. Federici, and M. Petruccioli (2000) Direct ammonium fumarate production by Rhizopus arrhizus under phosphorous limitation. Biotechnol. Lett. 22: 1043–1047.

Ling, L. B. and T. K. Ng (1989) Fermentation process for carboxylic acids. US patent 4,877,731.

Cao, N., J. Du, C. S. Gong, and G. T. Tsao (1996) Simultaneous production and recovery of fumaric acid from immobilized Rhizopus oryzae with a rotary biofilm contactor and an adsorption column. Appl. Environ. Microbiol. 62: 2926–2931.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kang, S.W., Lee, H., Kim, D. et al. Strain development and medium optimization for fumaric acid production. Biotechnol Bioproc E 15, 761–769 (2010). https://doi.org/10.1007/s12257-010-0081-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-010-0081-4