Abstract

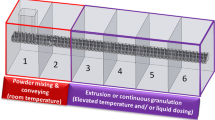

Wet granulation processes play a crucial role in solid oral dosage manufacturing processes. However, they are often designed empirically with poor efficiency. To implement quality-by-design, a more scientific understanding is desired to predict the effects of process and equipment design and material properties on the rate mechanisms governing wet granulation processes. In this study, a multi-dimensional compartmental population balance model of a twin screw granulation process is coupled with discrete element method simulations to evaluate mechanistic rate expressions describing aggregation, breakage, consolidation, and particle flow. Steady-state results are presented for various configurations of the screw elements. The effects of screw element configuration on product size distribution, porosity, and liquid distribution are presented and compared with experimental trends described in literature. Simulated results are consistent with experimental findings, demonstrating the model’s qualitative ability to predict the effects of screw element design and configuration on the particle-scale phenomena and process outcomes.

Similar content being viewed by others

References

Ai J, Chen J-F, Rotter JM, Ooi JY. Assessment of rolling resistance models in discrete element simulations. Powder Technol 2011;206(3):269–282.

Barrasso D, El Hagrasy A, Litster JD, Ramachandran R. Multi-dimensional population balance model development and validation for a twin screw granulation process. Powder Technology 270 Part B 2015a:612–621.

Barrasso D, Eppinger T, Pereira FE, Aglave R, Debus K, Bermingham SK, Ramachandran R. A multi-scale, mechanistic model of a wet granulation process using a novel bi-directional PBM-DEM coupling algorithm. Chem Eng Sci 2015b;123:500–513.

Barrasso D, Ramachandran R. A comparison of model order reduction techniques for a four-dimensional population balance model describing multi-component wet granulation processes. Chem Eng Sci 2012;80:380–392.

Barrasso D, Ramachandran R. Multi-scale modeling of granulation processes: bi-directional coupling of PBM with DEM via collision frequencies. Chem Eng Res Des 2015;93:304–317.

Barrasso D, Tamrakar A, Ramachandran R. A reduced order PBM-ANN model of a multi-scale PBM-DEM description of a wet granulation process. Chem Eng Sci 2014;119:319–329.

Barrasso D, Walia S, Ramachandran R. Multi-component population balance modeling of continuous granulation processes: a parametric study and comparison with experimental trends. Powder Technol 2013;241:85–97.

Bouffard J, Bertrand F, Chaouki J. A multiscale model for the simulation of granulation in rotor-based equipment. Chem Eng Sci 2012;81:106–117.

Braumann A, Kraft M, Mort PR. Parameter estimation in a multidimensional granulation model. Powder Technol 2010;197(3):196–210.

Cameron I, Wang F, Immanuel C, Stepanek F. Process systems modelling and applications in granulation: a review. Chem Eng Sci 2005;60(14):3723–3750.

Chaudhury A, Barrasso D, Pandey P, Wu H, Ramachandran R. Population balance model development, validation, and prediction of CQAs of a high-shear wet granulation process: towards QbD in drug product pharmaceutical manufacturing. J Pharm Innov 2014;9(1):53–64.

Chaudhury A, Kapadia A, Prakash AV, Barrasso D, Ramachandran R. An extended cell-average technique for a multi-dimensional population balance of granulation describing aggregation and breakage. Adv Powder Technol 2013;24(6):962–971.

Dhenge RM, Cartwright JJ, Hounslow MJ, Salman AD. Twin screw granulation: steps in granule growth. Int J Pharm 2012;438(162):20–32.

El Hagrasy A. Granulation rate processes in the kneading elements of a twin screw granulator. AIChE J 2013; 59(11):4100–4115.

Ennis BJ, Tardos G, Pfeffer R. A microlevel-based characterization of granulation phenomena. Powder Technol 1991;65(13):257–272.

Gantt JA, Cameron IT, Litster JD, Gatzke EP. Determination of coalescence kernels for high-shear granulation using DEM simulations. Powder Technol 2006;170(2):53–63.

Goldschmidt M, Weijers G, Boerefijn R, Kuipers J. Discrete element modelling of fluidised bed spray granulation. Powder Technol 2003;138(1):39–45.

Hagrasy AE, Hennenkamp J, Burke M, Cartwright J, Litster J. Twin screw wet granulation: influence of formulation parameters on granule properties and growth behavior. Powder Technol 2013;238:108–115.

Hassanpour A, Ghadiri M. Distinct element analysis and experimental evaluation of the heckel analysis of bulk powder compression. Powder Technol 2004;141(3):251–261.

Immanuel CD, Doyle FJ III. Solution technique for a multi-dimensional population balance model describing granulation processes. Powder Technol 2005;156(23):213–225.

Ingram GD, Cameron IT. Formulation and comparison of alternative multiscale models for drum granulation. Computer Aided Chemical Engineering 2005;20:481–486.

Iveson SM, Litster JD, Hapgood K, Ennis BJ. Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol 2001;117(12):3–39.

Kumar A, Vercruysse J, Toiviainen M, Panouillot P-E, Juuti M, Vanhoorne V, Vervaet C, Remon JP, Gernaey KV, Beer TD, Nopens I. Mixing and transport during pharmaceutical twin-screw wet granulation: experimental analysis via chemical imaging. Eur J Pharm Biopharm 2014;87(2):279–289.

Lee KT, Ingram A, Rowson NA. Comparison of granule properties produced using twin screw extruder and high shear mixer: a step towards understanding the mechanism of twin screw wet granulation. Powder Technol 2013; 238:91–98.

Liu LX, Litster JD, Iveson SM, Ennis BJ. Coalescence of deformable granules in wet granulation processes. AIChE J 2000;46(3):529–539.

Mangwandi C, Cheong Y, Adams M, Hounslow M, Salman A. The coefficient of restitution of different representative types of granules. Chem Eng Sci 2007;62(12):437–450.

Poon JM-H, Immanuel CD, Doyle III FJ, Litster JD. A three-dimensional population balance model of granulation with a mechanistic representation of the nucleation and aggregation phenomena. Chem Eng Sci 2008; 63(5):1315– 1329.

Ramachandran R, Barton PI. Effective parameter estimation within a multi-dimensional population balance model framework. Chem Eng Sci 2010;65(16):4884–4893.

Reinhold A, Briesen H. Numerical behavior of a multiscale aggregation model coupling population balances and discrete element models. Chem Eng Sci 2012;70:165–175.

Sayin R, Hagrasy AE, Litster J. Distributive mixing elements: towards improved granule attributes from a twin screw granulation process. Chem Eng Sci 2015;125:165–175.

Sen M, Barrasso D, Singh R, Ramachandran R. A multi-scale hybrid CFD-DEM-PBM description of a fluid-bed granulation process. Processes 2014;2(1):89–111.

Tardos GI, Khan MI, Mort PR. Critical parameters and limiting conditions in binder granulation of fine powders. Powder Technol 1997;94(3):245–258.

U.S Food and Drug Administration. 2006. Guidance for Industry: Q8 Pharmaceutical Development.

U.S. Food and Drug Administration. 2009. Guidance for Industry: Q8(R2) Pharmaceutical Development.

van den Dries K, Vromans H. Relationship between inhomogeneity phenomena and granule growth mechanisms in a high-shear mixer. Int J Pharm 2002;247(12):167–177.

Vercruysse J, Diaz DC, Peeters E, Fonteyne M, Delaet U, Assche IV, Beer TD, Remon J, Vervaet C. Continuous twin screw granulation: influence of process variables on granule and tablet quality. Eur J Pharm Biopharm 2012;82(1):205– 211.

Verkoeijen D, Pouw GA, Meesters GMH, Scarlett B. Population balances for particulate processes a volume approach. Chem Eng Sci 2002;57(12):2287–2303.

Acknowledgments

This work is supported by the National Science Foundation Engineering Research Center on Structured Organic Particulate Systems Grant NSF-ECC 0540855. The authors also thank Jim Litster (Purdue), Sean Bermingham (Process Systems Enterprise), Jianfeng Li (Process Systems Enterprise), Frances Pereira (Process Systems Enterprise), David Slade (Process Systems Enterprise), Ravindra Aglave (CD-adapco), Kristian Debus (CD-adapco), and Thomas Eppinger (CD-adapco) for contributing to discussions on this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barrasso, D., Ramachandran, R. Qualitative Assessment of a Multi-Scale, Compartmental PBM-DEM Model of a Continuous Twin-Screw Wet Granulation Process. J Pharm Innov 11, 231–249 (2016). https://doi.org/10.1007/s12247-015-9240-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-015-9240-7