Abstract

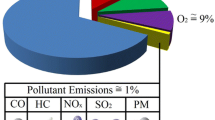

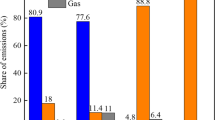

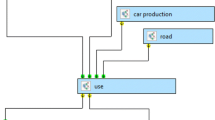

In the diesel engine after-treatment system of motor vehicles, Diesel Oxidation Catalytic (DOC) converter is used to purify hydrocarbons (HCs) consisting of oil and fuel residue, and Carbon Monoxide (CO) from the exhaust gas. The exhaust gas flowing through DOC converter experiences chemical reactions that oxidize CO and HCs which are formed by incomplete combustion. Reactive properties, geometric features and thermal properties are fundamental design elements of a DOC converter. Flow of the exhaust gas through the converter with these properties can be described using a mathematical model given by Partial Differential Equations (PDEs). In this work, a simulation program for solving these PDEs describing the mathematical model of DOC converter was developed. PDEs were solved by Finite Volume Method (FVM) for volume elements and an implicit method for time steps. Using the solution of PDEs, reduction of CO and HCs at the outlet of the converter was computed. Thus, our model can be used to simulate, or design DOC converters and to predict the reduction of CO and HCs from DOC converters.

Similar content being viewed by others

References

Baumann, W. W., Bunge, U., Frederich, O., Schatz, M. and Thiele, F. (2006). Manuskript zur Vorlesung: Finite-Volumen-Methode in der Numerischen Thermofluiddynamik. Institute of Fluid Mechanics and Technical Acoustics. Technical University of Berlin. Germany.

Chatterjee, D., Burkhardt, T., Rappe, T., Güthenke, A. and Weibel, M. (2009). Numerical simulation of DOC+DPF+SCR systems: DOC influence on SCR performance. SAE Int. J. Fuels and Lubricants 1, 1, 440–451.

Kabir, M. N., Issa-Salwe, A. and Ahmed, M. (2010). Modelling and simulation: Implementing selective catalytic reduction catalyst for removal of nitrogen oxides from exhaust gas of combustion engines. Int. J. Vehicle Systems Modelling & Testing 5, 4, 358–378.

Kaefer, S. (2004). Trochenharnstoff-SCR-System und Betriebsstrategie für Fahrzeuge mit Dieselmotor. Ph.D. Dissertation. Faculty of Mechanical and Process Engineering. Technical University of Kaiserslautern. Germany.

Koltsakis, G. C. and Stamatelos, A. M. (1997) Catalytic automotive exhaust after-treatment. Progress in Energy and Combustion Science 23, 1, 1–39.

Lafossas, F., Matsuda, Y., Mohammadi, A., Morishima, A. Inoue, M., Kalogirou, M., Koltsakis, G. and Samaras, Z. (2011). Calibration and validation of a diesel oxidation catalyst model: from synthetic gas testing to driving cycle applications. SAE Int. J. Engines 4, 1, 1586–1606.

Lepreux, O. (2009). Model-based Temperature Control of a Diesel Oxidation Catalyst. Ph.D. Dissertation. ICMS — Information. Communication. Modélisation et Simulation. Mines Paristech.

Lepreux, O., Creff, Y. and Petit, N. (2012). Model-based temperature control of a diesel oxidation catalyst. J. Process Control 22, 1, 41–50.

Montenegro, G. and Onorati, A. (2009). 1D thermo-fluid dynamic modeling of reacting flows inside three-way catalytic converters. SAE Int. J. Engines 2, 1, 1–16.

Onorati, A., Ferrari, G., D'Errico, G. and Montenegro, G. (2002). The prediction of 1D unsteady flows in the exhaust system of a S.I. engine including chemical reactions in the gas and solid phase. SAE Paper No. 2002-01-0003.

Press, W. H., Teukolsky, S. A., Flannery, B. P. and Vetterling, W. T. (1992). Numerical Recipes in C: The Art of Scientific Computing. 2nd edn. Cambridge University Press. Cambridge.

Salomons, S. (2008). Kinetic Models for a Diesel Oxidation Catalyst. Department of Chemical and Materials Engineering. University of Alberta. Canada.

Salomons, S., Hayes, R. E. and Votsmeier, M. (2009). The promotion of carbon monoxide oxidation by Hydrogen on supported platinum catalyst. Applied Catalysis A: General 352, 1–2, 27–34.

Sampara, C. S., Bissett, E. J. and Assanis, D. (2008). Hydrocarbon storage modeling for diesel oxidation catalysts. Chemical Engineering Science 63, 21, 5179–5192.

Smith, J. M., Van Ness, H. C. and Abbott, M. M. (2005). Introduction of Chemical Engineering Thermodynamics. 7th edn. McGraw Hill Higher Education. New York.

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer. New York.

Voltz, S. E., Morgan, C. R., Liederman, D. and Jacod, S. M. (1973). Kinetics study of carbon monoxide and propylene oxidation on platinum catalysts. Ind. Eng. Chem. Prod. Res. Dev., 12, 294.

Wang, T. J., Baek, S. W. and Lee, J.-H. (2008). Kinetic parameter estimation of a diesel oxidation catalyst under actual vehicle operating conditions. Industrial & Engineering Chemistry Research 47, 8, 2528–2537.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kabir, M.N., Alginahi, Y. & Islam, K. Simulation of oxidation catalyst converter for after-treatment in diesel engines. Int.J Automot. Technol. 16, 193–199 (2015). https://doi.org/10.1007/s12239-015-0021-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-015-0021-6