Abstract

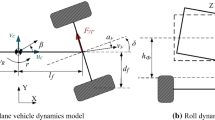

In this research, the concept of the kinematic roll center is reviewed from the viewpoint of three-dimensional spatial kinematics. The theory of screws, which is widely used in spatial kinematics and robotics, is used to prove the validity of the conventional planar methods for finding the roll center in an initial symmetric vehicle position. The kinematic roll axis, which is referred to as the roll twist axis in this paper, is defined as the instantaneous screw axis of the vehicle body in roll motion with respect to the ground, and a three-dimensional method to determine the roll twist axis of a full-vehicle model in an initial symmetric position is introduced. The proposed method is based on screw theory, which relates the kinematics of a full-vehicle model to the statics of the full-vehicle model using the concepts of screws, twists, wrenches, the rate of working, and the reciprocity of screws. The results of the proposed three-dimensional method are compared with those of the conventional planar methods, and it is found that the conventional methods are valid under the assumption that the vehicle is in a symmetric situation.

Similar content being viewed by others

References

Ball, R. S. (1900). A Treatise on the Theory of Screws. Cambridge University Press. New York.

Davidson, J. K. and Hunt, K. H. (2004). Robots and Screw Theory: Applications of Kinematics and Statics to Robotics. Oxford University Press. New York.

Dixon, J. C. (1987). The roll-centre concept in vehicle handling dynamics. Proc. Institution of Mechanical Engineers 201,D1, Part D, Transport Engineering, 69–78.

Dixon, J. C. (1996). Tire, Suspension and Handling. 2nd Edn. SAE Int. Warrendale.

Gerrard, M. B. (1999). Roll centres and jacking forces in independent suspensions — A first principles explanation and a designer’s toolkit. SAE Paper No. 1999-01-0046.

Gillespie, T. D. (1992). Fundamentals of Vehicle Dynamics. SAE Inc. Warrendale.

Goodsell, D. (1995). Dictionary of Automotive Engineering, 2nd edn. SAE Inc. Warrendale.

Hunt, K. H. (1978). Kinematic Geometry of Mechanisms. Clarendon Press. Oxford.

Jones, R. A. (1999). Understanding vehicle roll using mechanism simulation software. SAE Paper No. 1999-01-0030.

Jung, J., Shim, T. and Gertsch, J. (2009). A vehicle rollstability indicator incorporating roll-center movements. IEEE Trans. Vehic. Tech., 58, 4078–4087.

Lee, J. K. (2007). Screw Axis Theory and its Applications to the Behavior Analysis of Full-Vehicle Models and the Synthesis of Suspension System. Ph. D. Dissertation. Korea University. Seoul. Korea.

Lee, J. K. and Shim, J. K. (2006). Roll center analysis of a half-car model using pole for small displacement. Int. J. Automotive Technology 7,7, 833–839.

Lee, J. K. and Shim, J. K. (2006). Roll motion analysis of a full vehicle model using screw theory. 31th FISITA World Automotive Cong., Yokohama, Japan, F2006V114.

Milliken, W. F. and Milliken, D. L. (1995). Race Car Vehicle Dynamics. SAE Int. Warrendale.

Mitchell, W. C. (1998). Asymmetric roll centers. SAE Paper No. 983085.

Mitchell, W. C. (2006). Force-based roll centers and an improved kinematic roll center. SAE Paper No. 2006-01-3617.

Moline, D., Vaduri, S. and Law, E. H. (2000). Fidelity of vehicle models using roll center principles. SAE Paper No. 2000-01-0693.

Morse, P. and Starkey, J. M. (1996). A force-based roll center model for vehicle suspensions. SAE Paper No. 962536.

Raghavan, M. (2005). Suspension synthesis for N:1 Roll center motion. ASME J. Mech. Des., 127, 673–678.

Reimpell, J., Stoll, H. and Betzler, J. W. (2001). The Automotive Chassis. 2nd Edn. SAE Inc. Warrendale.

Roth, B. (1984). Screws, motors, and wrenches that cannot be bought in a hardware store. Proc. 1st Int. Symp. Robotics Research, 679–693.

Suh, C. H. (1991). Suspension analysis with instant screw axis theory. SAE Paper No. 910017.

Tsai, L. W. (1999). Robot Analysis: The Mechanics of Serial and Parallel Manipulators. John Wiley & Sons. New York.

Yuan, M. S. C. and Freudenstein, F. (1971). Kinematic analysis of spatial mechanisms by means of screw coordinates. Part 1-Screw coordinates. Trans. ASME, J. Eng. For Industry, 93, 27–33.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.K., Shim, J.K. Validity and limitations of the kinematic roll center concept from the viewpoint of spatial kinematics using screw theory. Int.J Automot. Technol. 12, 769–775 (2011). https://doi.org/10.1007/s12239-011-0089-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-011-0089-6