Abstract

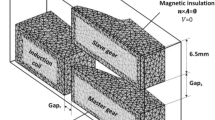

In new slim torque converters, lock-up clutches are used to provide high fuel efficiency at low speed. However, the slimness of the converters causes difficulty in heat dissipation, which may damage the friction material and shorten its life span. A cooling hole in the lock-up piston reduces the heat but also reduces the torque because oil flows through the hole due to the pressure difference between the two faces of the piston. In the early stages of the development of this type of torque converter, designers must consider the minimum flow rate required to cool the friction material and the minimum torque capacity required to transmit the engine torque. This research explored two methods of estimating these parameters. In the first method, an estimation equation was derived by combining the response surface method with physical properties such as the centrifugal force, a sudden expansion, a sudden contraction, and the steady flow energy equation. The second method involved the use of an artificial neural network. The feasibility of the estimates based on statistics and on the artificial neural network were confirmed in the design stage by comparing experimental and estimated data. An estimation program was created using the C#.Net language and has been used for actual torque converter designs by the Korea Powertrain Company.

Similar content being viewed by others

References

Aleksendric, D. and Duboka, C. (2007). Fade performance prediction of automotive friction materials by means of artificial neural networks. Wear, 262, 778–790.

Choi, J.-C., Kim, Y.-H. and Park, J.-H. (2003). Optimal reheating condition of semi-solid material in semisolid forging by neural network. Int. J. Precision Engineering and Manufacturing, 4, 49–56.

Demuth, H., Beale, M. and Hagan, M. (2008). Matlab — Neural Network Toolbox, User’s Guide 6.0.

Hosoz, M. and Ertunc, H. M. (2006). Artificial neural network analysis of an automobile air conditioning system. Energy Conversion and Management, 47, 1574–1587.

Jeong, J.-W. and Mumma, S. A. (2004). Simplified cooling capacity estimation model for top insulated metal ceiling radiant cooling panels. Applied Thermal Engineering, 24, 2055–2072.

Kim, B. S., Ha, S. B., Lim, W. S. and Cha, S. W. (2008). Performance estimation model of a torque converter part I: Correlation between the internal flow field and energy loss coefficient. Int. J. Automotive Technology 9,2, 141–148.

Kumar, S. (2005). Estimation of design parameters for thermal performance evaluation of box-type solar cooker. Renewable Energy, 30, 1117–1126.

Myers, R. H. and Montgomery, D. C. (1995). Response Surface Methodology: Process and Product Optimization Using Designed Experiments. John Wiley & Sons. New York.

Ochi, T., Takeuchi, H., Kimura, H. and Watanabe, K. (2006). Development of a super-flat torque converter for the new toyota FWD 6-speed automatic transaxle. SAE Papers No. 2006-01-0149.

White, F. M. (1994). Fluid Mechanics. McGraw-Hill. New York. 335–342.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chun, D.M., Lee, J.C., Yeo, J.C. et al. Capacity estimation of torque converters with piston holes using the response surface method and an artificial neural network. Int.J Automot. Technol. 12, 273–280 (2011). https://doi.org/10.1007/s12239-011-0032-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-011-0032-x