Abstract

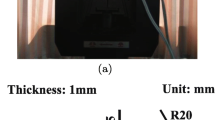

To more accurately manufacture an auto-body workpiece, a predictive compensation factor method was used to predict the workpiece’s springback, and the factors influencing springback are introduced. Based on this method, a numerical simulation was produced to simulate the springback compensation after distortion of the workpiece. After analyzing the simulation results, a compensation method was introduced to reduce the springback influence on an actual workpiece. Here, we used a fortified B-pillar, which is a kind of longitudinal stand-frame workpiece, made with a high-strength steel material (TRIP700). The simulation results indicated that the proposed method is feasible and can be efficiently used for predicting the distortion of springback compensation of an auto-body workpiece.

Similar content being viewed by others

References

Hu, P. and Li, Y.-X. (2003). Quantitative prediction for springback of unloading and trimming in sheet metal stamping forming. Chinese J. Mechanical Engineering (English Edn.) 16,2, 190–192, 196.

Geng, L. and Zhao, K. (2003). Springback compensation for ultra high strength stamping. SAE Paper No. 2003-01-0686.

Huette, H. (2001). Untersuchungenzum Rueckfederungs-Verhalten Hochfester Stahlblechwerstoffe Beim Tiefziehen. Ph. Dissertation. Universitaet Hannover.

Lang, K. (1990). Umformtechnik, Handbuch fuer Industrie und Wissenschaft, Band3; Blechbearbeitung. Springer-Vorlag. Berlin. Heidelberg.

Zhang, L. and Cheng, F.-L. (1995). Springback compensation in die surface geometry using simulation methodology. IBEC, 95 Body Assembly and Manufacturing, 98–103.

Zhang, L. and Wu, J. (2004). A new concept on stamping die surface compensation. 8th Int. LS-DYNA Users Conf.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X.K., Zheng, G.J., Hu, J.N. et al. Compensation factor method for modeling springback of auto parts constructed with high-strength steel. Int.J Automot. Technol. 11, 721–727 (2010). https://doi.org/10.1007/s12239-010-0085-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-010-0085-2