Abstract

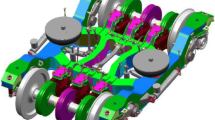

Surface topology, cone angle and the forces acting on the cone of the clutch type limited slip differential (LSD) are major design parameters for the bias ratio and the noise condition. Therefore much research has been dedicated to these developments but the results have been used to submit patents. A new cone type limited slip differential for sport utility vehicles and recreational vehicles, which has a very simple structure and easy compliance with the vehicle performance, has been developed by the axiomatic approach and the ultrasonic nano crystal surface modification (UNSM) technology. The design criteria and optimal value of the design parameters are determined by the axiomatic approach utilizing CAE tools. Test methodologies in a test rig and in a vehicle were also developed. Test results showed good performance of bias ratio and noise level but durability is still under testing. This study is an extension of F2006P266, FISITA 2006.

Similar content being viewed by others

References

Allen, J. (2002a). 4-Wheeler’s Bible. MBI Publishing Company. Minnesota.

Allen, J. (2002b). 4-Wheeler’s Bible. MBI Publishing Company. Minnesota.

APM WinMachine, www.designmecha.co.kr/product/DDS.

Atsushi, O., Futoshi, K., Tsutomi, M., Takayuki, U. and Ryuichi, F. (2006). Development of a procedure to detect quantified abnormal noise. Fujitsu Ten Tech. J., 26, 32–41.

CATIA, www-306.ibm.com/software/applications/plm/catiav5/

Cho, I. H., Song, G. H., Kim, C. S., Nobuhide, A., Suh, C. M., Park, J. H., Combs, A., Park, J. and Pyoun, Y. S. (2005). Nano structured surface modification of tool steel and its beneficial effects in mechanical properties. J. Mechanical Science and Technology, 19, 2151–2156.

Forrest, J. L. and Leeper, R. (1999). Cone Clutch Structure Having Recessed Areas for Use in a Limited Slip Differential. United States Patent, No. US 6,261,202 B1.

Gilles, T. (2003). Automotive Service: Inspection, Maintenance Repair. 2nd edn. Thomson Delmar Learning. New York.

Hwang, Y.-D., Cha, S.-W. and Kang, Y.-J. (2002). Tool development for evaluation of quantitive independency between FRs in axiomatic design. Int. J. Korean Society of Precision Engineering 3, 2, 52–60.

Isobe, H., Hara, K., Kyusojin, A., Okada, M. and Yoshihara, H. (2007). Ultrasonically assisted grinding for mirror surface finishing of dies with electroplated diamond tools. Int. J. Precision Engineering And Manufacturing 8, 2, 38–43.

Jarvis, R. P. and Young, A. J. (1993). A new form of limited slip differential. SAE Paper No. 930672.

Kim, B. S. and Suh, M. W. (1999). Topology optimization using an optimality criteria method. Trans. Korean Society Automotive Engineers 7, 8, 224–331.

Prevey, P. S., Jayaraman, N. and Ravindranath, R. A. (2005). Use of residual compression in design to improve damage tolerance in Ti-6Al-4V aero engine blade dovetails. Proc. 10th National Turbine Engine HCF Conf., New Orleans, LA.

Pyoun, Y. S. (2000). Collection of technical papers on development of LSD. Technical Paper 2000 of Institute for Manufacturing Systems Technology, Sun Moon University, 8, 123–125.

Pyun, Y. S., Jang, Y. D., Cho, I. H., Park, J. H., Combs, A. and Lee, Y. C. (2006a). Design evaluation of no spin differential models using the axiomatic approach. Int. J. Automotive Technology 7, 5, 595–601.

Pyun, Y. S., Jang, Y. D., Cho, I. H., Park, J. H., Combs, A. and Lee, Y. C. (2006b). Evolutionary design of no spin differential models for off-road vehicles using the axiomatic approach. Int. J. Automotive Technology 7, 7, 795–801.

Shigley, J. E. and Mischke, C. R. (1996). Standard Handbook of Machine Design. 2nd edn.. McGraw-Hil. USA.

Suh, N. P. (1990). The Principles of Design. Oxford University Press. New York.

Suh, N. P. (2001). Axiomatic Design: Advances and Applications. CIRP Design Book Series. Oxford University Press. New York.

UNSM Technology is Patent Technology of DesignMecha Co. Ltd., www.desigmecha.co.kr

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pyoun, Y.S., Kim, H.T., Lee, Y.C. et al. Development of evolutionary cone type LSD for SUV/RV utilizing the axiomatic approach and the ultrasonic nano crystal surface modification technology. Int.J Automot. Technol. 9, 61–70 (2008). https://doi.org/10.1007/s12239-008-0008-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-008-0008-7