Abstract

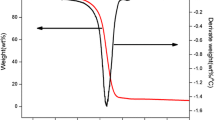

Many characteristics contribute to the effectiveness of textile products. For fire-protective fabrics, maintaining the physical integrity and protective properties over time is incredibly important. This fabric integrity can be affected as a result of chemical changes resulting from exposure to service conditions, for example water splashes and immersion. This study investigates the chemical components that were found in the hydrothermal aging water of 11 fire-protective fabrics subjected to water immersion at 90 °C for up to 50 days. Two techniques based on two-dimensional gas chromatography were used. Two-dimensional gas chromatography–time-of-flight mass spectrometry (GC × GC–TOFMS) was employed for comprehensive non-targeted qualitative analysis (NTA) while the quantification of compounds was performed with two-dimensional gas chromatography–flame ionization detection (GC × GC–FID). A total of 276 unique compounds of interest were identified in the aging water of the fabrics. Several of them were successfully traced to their purpose in textile manufacturing and would indicate the decomposition of the high-performance fibers making the fabrics, leaching of dyes and pigments, and/or degradation of the fabric finish. The knowledge generated during this study, both in terms of the extraction and analysis protocol and evidence of the degradation processes, is invaluable information for advancing the understanding of the aging of fire-protective fabrics and enhancing the safety of firefighters and others exposed to heat and flame.

Similar content being viewed by others

Data Availability

Data are available from the corresponding author upon reasonable request.

References

A. Shaid, L. Wang, R. Padhye, Firefighters’ Clothing and Equipment: Performance, Protection, and Comfort, 1st edn. (Taylor & Francis, New York, 2018), pp.01–29

S. Mandal, S. Gaan, M. Camenzind, S. Annaheim, R.M. Rossi, Thermal Analysis of Textiles and Fibers (Woodhead Publishing, Cambridge, 2020), pp.355–387. https://doi.org/10.1016/B978-0-08-100572-9.00021-5

S. Rebouillat, High-Performance Fibres, 1st edn. (Woodhead Publishing, Cambridge, 2001), pp.23–61

G. Bhat, Structure and Properties of High-Performance Fibers (Woodhead Publishing, Cambridge, 2017), pp.1–4. https://doi.org/10.1016/B978-0-08-100550-7.00001-2

J.W. Gooch, Encyclopedic Dictionary of Polymers (Springer, New York, 2011), pp.562–562

A.R. Horrocks, H. Eichhorn, H. Schwaenke, N. Saville, C. Thomas, High-Performance Fibres, 1st edn. (Woodhead Publishing, Cambridge, 2001), pp.281–324

F. Sloan, Structure and Properties of High-Performance Fibers (Woodhead Publishing, Cambridge, 2017), pp.113–140. https://doi.org/10.1016/B978-0-08-100550-7.00005-X

M. Knop, Trends for firefighters: red, more than just a popular colour. (Tencate Prot. Fabr. 2020). https://eu.tencatefabrics.com/blog/trends-for-firefighters-red-more-than-just-a-popular-colour. Accessed 17 Feb 2023.

R.M. Spayne, Why do wildland firefighters wear yellow? (Fire Buy. Int., 2022). https://firebuyer.com/why-do-wildland-firefighters-wear-yellow/. Accessed 17 Feb 2023.

E.A. Manyukov, S.F. Sadova, N.N. Baeva, V.A. Platonov, Fibre Chem. 37, 54 (2005). https://doi.org/10.1007/s10692-005-0053-1

M. Morris, X.P. Ye, C.J. Doona, Polymers 13, 1492 (2021). https://doi.org/10.3390/polym13091492

B.L. Kaul, Synthetic Fibre Dyeing (West Yorkshire, Bradford, 2004), p.230

Kevlar®Aramid Fiber Technical Guide (DuPont, 2019). https://www.dupont.com/news/kevlar-properties.html. Accessed 12 Mar 2020.

Technora- an outstanding para-aramid combining unique properties (Teijin, n.d.). https://pdf.nauticexpo.com/pdf/teijin-aramid-bv/outstanding-para-aramid-combining-unique-properties/30430-111463.html. Accessed 17 Feb 2023.

M.S. Hoque, P.I. Dolez, J. Appl. Polym. Sci. 140(32), e54255 (2023). https://doi.org/10.1002/app.54255

M. McQuerry, S. Klausing, D. Cotterill, E. Easter, Fire Technol. 51, 1149 (2015). https://doi.org/10.1007/s10694-014-0446-x

M.L. Cinnamon, Post use analysis of firefighter turnout gear-phase III, Masters Thesis, University of Kentucky, Lexington, Kentucky, USA, 2013

D.G. Cotterill, Post use analysis of firefighter turnout gear-phase I, Masters Thesis, University of Kentucky, Lexington, Kentucky, USA, 2009

S.L. Trenkamp, Post use analysis of firefighters turnout gear-phase II, Masters Thesis, University of Kentucky, Lexington, Kentucky, USA, 2011

T.L. Vogelpohl, Post use evaluation of firefighters turnout coat, Masters Thesis, University of Kentucky, Lexington, Kentucky, USA, 1996

M. Rezazadeh, Evaluation of performance of in-use firefighters’ protective clothing using on-destructive tests, PhD Thesis. University of Saskatchewan. Saskatoon, SK, 2014

M.S. Hoque, A. Saha, H.J. Chung, P.I. Dolez, J. Appl. Polym. Sci. 139(30), e52666 (2022). https://doi.org/10.1002/app.52666

C. Arrieta, É. David, P.I. Dolez, T. Vu-Khanh, Polym. Degrad. Stab. 96, 8 (2011). https://doi.org/10.1016/j.polymdegradstab.2011.05.015

J. Chin, A. Forster, C. Clerici, L. Sung, M. Oudina, K. Rice, Polym. Degrad. Stab. 92, 7 (2007). https://doi.org/10.1016/j.polymdegradstab.2007.03.030

I. Dolez, Y. Malajati, Performance of Protective Clothing and Equipment: Innovative Solutions to Evolving Challenges (ASTM International, West Conshohocken, 2020), pp.100–113. https://doi.org/10.1520/STP162420190079

K. Slater, Text. Prog. 21, 1 (1991). https://doi.org/10.1080/00405169108688851

X. Yang, C. Wang, H. Shao, Q. Zheng, Sci. Total. Environ. 694, 133494 (2019). https://doi.org/10.1016/j.scitotenv.2019.07.300

X. Gao, P. Huang, Q. Huang, K. Rao, Z. Lu, Y. Xu, G.W. Gabrielsen, I. Hallanger, M. Ma, Z. Wang, Environ. Pollut. 253, 1 (2019). https://doi.org/10.1016/j.envpol.2019.06.094

D. Schemeth, N.J. Nielsen, J.T. Andersson, J.H. Christensen, Chemosphere 235, 175 (2019). https://doi.org/10.1016/j.chemosphere.2019.06.149

R. Avagyan, M. Åberg, R. Westerholm, Chemosphere 163, 313 (2016). https://doi.org/10.1016/j.chemosphere.2016.08.039

J. Beens, J. Blomberg, P.J. Schoenmakers, J. High Resolut. Chromatogr. 23, 182 (2000). https://doi.org/10.1002/(SICI)1521-4168(20000301)23:3%3c182::AID-JHRC182%3e3.0.CO;2-E

D.M. Mazur, T.B. Latkin, D.S. Kosyakov, A.Y. Kozhevnikov, N.V. Ulyanovskii, A.G. Kirilov, A.T. Lebedev, Environ. Pollut. 265, 114885 (2020). https://doi.org/10.1016/j.envpol.2020.114885

T.A. Johnson, M.D.S. Armstrong, A.P. de la Mata, J.J. Harynuk, J. Chromatogr. Open 2, 100070 (2022). https://doi.org/10.1016/j.jcoa.2022.100070

M. Rezaee, Y. Assadi, M.R.M. Hosseini, E. Aghaee, F. Ahmadi, S. Berijani, J. Chromatogr. A (2006). https://doi.org/10.1016/j.chroma.2006.03.007

A.T. James, A.J. Martin, Biochem. J. 50, 679 (1952). https://doi.org/10.1042/bj0500679

Z. Wang, M. Fingas, J. Chromatogr. A 774, 51 (1997). https://doi.org/10.1016/S0021-9673(97)00270-7

K.D. Nizio, T.M. McGinitie, J.J. Harynuk, J. Chromatogr. A 1255, 12 (2012). https://doi.org/10.1016/j.chroma.2012.01.078

A.M. Muscalu, T. Górecki, TrAC Trends Anal. Chem. 106, 225 (2018). https://doi.org/10.1016/j.trac.2018.07.001

Q. Guo, X. Li, J. Yu, H. Zhang, Y. Zhang, M. Yang, N. Lu, D. Zhang, Anal. Methods 7, 2458 (2015). https://doi.org/10.1039/C4AY03026E

D.C. Harris, C.A. Lucy, Quantitative Chemical Analysis, 10th edn. (W.H. Freeman, New York, 2020)

N.J. Abbott, S. Schulman, J. Ind. Text. 6, 1 (1976). https://doi.org/10.1177/152808377600600

J.X. Chan, A. Hassan, J.F. Wong, K. Majeed, Encyclopedia of Materials: Plastics and Polymers (Elsevier, Amsterdam, 2022), pp.237–248

W.D. Schindler, P.J. Hauser, Chemical Finishing of Textiles, 1st edn. (Woodhead Publishing Limited, Cambridge, 2004), pp.43–50

R.J. Farn, Chemistry and Technology of Surfactants (Blackwell Publishing Ltd, Oxford, 2006), pp.300–309

Y. Yang, J. Yu, H. Xu, B. Sun, Porous Lightweight Composites Reinforced with Fibrous Structures (Springer, Berlin, 2017)

K.L. Hatch, H.I. Maibach, Handbook of Occupational Dermatology (Springer, Berlin, 2000), pp.622–636

Teijin Ltd, Method for producing aramid fiber, JP3187226B2 (13 December 1993)

M. Jaffe, A.J. East, Handbook of Fiber Chemistry, 3rd edn. (Taylor & Francis, Boca Raton, 2007), pp.1–30

R. Avagyan, G. Luongo, G. Thorsén, C. Östman, Environ. Sci. Pollut. Res. 22, 5842 (2015). https://doi.org/10.1007/s11356-014-3691-0

K.T. Chung, J. Environ. Sci. Heal. Part C 34, 233 (2016). https://doi.org/10.1080/10590501.2016.1236602

C. Liao, U.J. Kim, K. Kannan, Environ. Sci. Technol. 52, 5007 (2018). https://doi.org/10.1021/acs.est.7b05493

S. Benkhaya, S. M’rabet, A. El Harfi, Heliyon 6, e03271 (2020). https://doi.org/10.1016/j.heliyon.2020.e03271

R. Saranya, J. Jayapriya, A. Tamilselvi, Color. Technol. 128, 440 (2012). https://doi.org/10.1111/j.1478-4408.2012.00397.x

PubChem, Natl. Libr. Med. Natl. Cent. Biotechnol. Inf. (2005). https://pubchem.ncbi.nlm.nih.gov/compound/2_4-Diisocyanato-1-methylbenzene.

T. Heidenfelder, J. Detering, G. Wagenblast, Method for providing textile material with UV protection, 20040074012 (6 Aug 2003)

H.M. Fahmy, H.M.Y. Okda, M.H. El-Rafie, A.G. Hassabo, M.A. Youssef, Egypt. J. Chem. 65, 499 (2022). https://doi.org/10.21608/ejchem.2021.89016.4275

Environment Canada and Health Canada, Aromatic Azo- and Benzidine-Based Substances (2012). https://www.canada.ca/en/health-canada/services/chemical-substances/substance-groupings-initiative/aromatic-azo-benzidine-based.html. Accessed 12 Feb 2023.

J. Liang, X.-A. Ning, M. Kong, D. Liu, G. Wang, H. Cai, J. Sun, Y. Zhang, X. Lu, Y. Yuan, Environ. Pollut. 231, 115 (2017). https://doi.org/10.1016/j.envpol.2017.08.006

M.S. Hoque, P.I. Dolez, in 10th Eur. Conf. Prot. Clothing. Prot. Challenges a Chang. World. 9–12 May 2023, Arnhem, Netherlands, edited by K. Kuklane and C. Mertens (Arnhem, 2023), pp. 108–109. https://doi.org/10.7939/r3-nfnj-pw50

G. Derombise, E. Chailleux, B. Forest, L. Riou, N. Lacotte, L. Vouyovitch Van Schoors, P. Davies, Polym. Eng. Sci. 51, 1366 (2011). https://doi.org/10.1002/pen.21922

A.C. Kogawa, B.G. Cernic, L.G.D.D. Couto, H.R.N. Salgado, Saudi Pharm. J. 25, 934 (2017). https://doi.org/10.1016/j.jsps.2017.02.006

R.J. Chudgar, Kirk-Othmer Encycl. Chem. Technol. (2000). https://doi.org/10.1002/0471238961.01261503082104.a01

S. Houshyar, R. Padhye, S. Ranjan, S. Tew, R. Nayak, J. Ind. Text. 48, 77 (2018). https://doi.org/10.1177/1528083717725112

REIMA, Manufacturing Restricted Substance List (2022). https://assets.ctfassets.net/u9gy9w9wtdqj/6aboDrzVyLHiiBH40ek88j/4637a69dfcd89b73be246e75b6502aff/20220207_Reima_Restricted_Substance_List_RRSL_incl._bluesign.pdf. Accessed 12 Feb 2023.

Canada Ministry of Environment and Health, Screening Assessment for TDIs (2008). https://www.ec.gc.ca/ese-ees/default.asp?lang=En&n=69A64ACA-1. Accessed 12 Feb 2023.

Acknowledgements

This project has received the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) [STPGP 521866-18 and RGPIN-2019-5583]. The authors also want to acknowledge the support provided by the Protective Clothing and Equipment Research Facility (PCERF) in the Human Ecology Department and the University of Alberta Department of Chemistry. They would like to thank Innotex and DuPont for graciously providing the fabrics used in the study.

Funding

This article is funded by Natural Sciences and Engineering Research Council of Canada, STPGP 521866, Patricia I Dolez, RGPIN-2019-5583, Patricia I Dolez.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Authors have no conflict of interest to declare.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hoque, M.S., Johnson, T., de la Mata, P. et al. Analysis of Hydrothermal Aging Water of Fire-Protective Fabrics Using GC × GC–TOFMS and FID. Fibers Polym 25, 1925–1948 (2024). https://doi.org/10.1007/s12221-024-00540-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-024-00540-5