Abstract

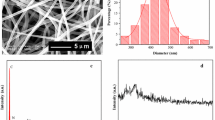

Color change technology offers unique and challenging opportunities. Thermo-responsive color-changing nanofibers with reversibility have great potential as thermal sensors due to their increased sensitivity and fast response. Herein, polycaprolactone (PCL) nanofibers were produced by adding a leuco-based thermochromic dye with various concentrations (1%, 3%, and 5% wt corresponding to PCL1, PCL3, and PCL5, respectively). The color-changing properties with repetitive heating and cooling were studied, and the effect of dye concentration on the nanofiber properties was determined. The surface properties, dye presence, thermal and mechanical properties were analyzed by SEM–EDS, FTIR, DSC, and tensile tests. Finally, the color change properties were monitored by 1000 heating and cooling cycles between 20 and 40 °C. Thermochromic PCL nanofibers were successfully produced by electrospinning. However, some agglomerates were observed on the nanofibers with increasing dye concentration in SEM images. It was seen that the optimum dye concentration was 3% in terms of the electrospinnability. For PCL5, both presence of carbon, oxygen, nitrogen, and fluorine in EDS spectra, the shifted peaks at 2917 and 2849 cm−1, and the new peaks at 1558, 1517, 1330, 1274, 1213 and 883 cm−1 in FTIR spectra confirmed that dye had been successfully incorporated into the PCL structure. The dye addition caused a decrease in the crystallization degrees, which resulted in lower mechanical properties. PCL5 had the lowest modulus. Color measurements showed that 1% of dyes concentration was not sufficient for the thermochromic property, and the color change was still visually detectable for PCL3 and PCL5 even after 1000 heating and cooling cycles. Color change activation temperature (TA) was confirmed between 30 and 32 °C, and the stability of color change was confirmed for 1000 heating and cooling cycles. After 1000 heating and cooling cycles, the color change was still detectable for PCL3 and PCL5. Consequently, this study showed that reversible thermochromic PCL nanofibers could be promising materials for future sensor applications.

Similar content being viewed by others

Data Availability

The data supporting the findings of this study are available within the article and/or from the authors upon reasonable request.

References

W. Wu, Y. Wang, Z. Zhang, F. Wang, S. Lu, X. Chen, Dye. Pigment. 204, 110406 (2022). https://doi.org/10.1016/J.DYEPIG.2022.110406

N. Shen, S. Chen, R. Huang, J. Huang, J. Li, R. Shi, S. Niu, A. Amini, C. Cheng, Mater. Today Energy 21, 100827 (2021). https://doi.org/10.1016/J.MTENER.2021.100827

L. Arneill, Australian Company Introduces BPA Free Bottle That Changes Colour. (https://www.growingyourbaby.com/australian-company-introduces-bpa-free-bottle-that-changes-colour/. Accessed 29 May 2023)

C.G. Granqvist, G.A. Niklasson, Buildings 7(1), 1–20 (2017). https://doi.org/10.3390/buildings7010003

X. Chen, J. Yoon, Dye. Pigment. 89(3), 194–198 (2011). https://doi.org/10.1016/j.dyepig.2009.12.015

Z. Ahmed, Y. Wei, R. Torah, J. Tudor, Electron. Lett. 52(19), 1601–1603 (2016). https://doi.org/10.1049/EL.2016.1073

E. Schoolaert, R. Hoogenboom, K. De Clerck, Adv. Funct. Mater. 27(38), 1702646 (2017). https://doi.org/10.1002/ADFM.201702646

J.M.A. Mancipe, S.V.G. Nista, G.E.R. Caballero, L.H.I. Mei, J. Appl. Polym. Sci. 138(11), 50039 (2021). https://doi.org/10.1002/APP.50039

N. Eslahi, T. Fatemi, M. Varsei, S. Bazgir, Sci. Iran. 27(6), 3447–3453 (2020). https://doi.org/10.24200/SCI.2020.55714.4369

O. Mapazi, K.P. Matabola, R.M. Moutloali, C.J. Ngila, Polymer (Guildf) 149, 106–116 (2018). https://doi.org/10.1016/J.POLYMER.2018.06.028

N. Moazeni, M. Latifi, A.A. Merati, S. Rouhani, Soft Matter 13(44), 8178–8187 (2017). https://doi.org/10.1039/C7SM01252G

Y. Guan, L. Zhang, D. Wang, J.L. West, S. Fu, Mater. Des. 147, 28–34 (2018). https://doi.org/10.1016/J.MATDES.2018.03.030

M.L. de Oliveira Peres, E.T. Neto, A.A. De Queiroz, A.A. de Queiroz, IEEE Sens. Lett. 5(3), 2000304 (2021). https://doi.org/10.1109/LSENS.2021.3058056

Y. Jin, Y. Bai, Y. Zhu, X. Li, M. Ge, Dye. Pigment. 146, 567–575 (2017). https://doi.org/10.1016/J.DYEPIG.2017.07.062

M.W. Williams, J.A. Wimberly, R.M. Stwodah, J. Nguyen, P.A. D’Angelo, C. Tang, A.C.S. Appl, Polym. Mater. 5(4), 3065–3078 (2023). https://doi.org/10.1021/acsapm.3c00222

P.G. Saiz, A. Reizabal, J.L. Vilas-Vilela, S. Lanceros-Mendez, P.D. Dalton, A.C.S. Appl, Polym. Mater. 5(6), 3883–3887 (2023). https://doi.org/10.1021/acsapm.3c00427

H.S. Jeon, J.H. Kim, M.B.G. Jun, Y.H. Jeong, Materials (Basel) 14(13), 3460 (2021). https://doi.org/10.3390/ma14133460

Y. He, S. Sun, N. Han, X. Zhang, W. Li, J. Mater. Sci. 55(27), 12921–12939 (2020). https://doi.org/10.1007/s10853-020-04936-5

J. Pan, B. Hao, P. Xu, D. Li, L. Luo, J. Li, Z. Xia, D. Cheng, A. Xu, G. Cai, X. Wang, Chem. Eng. J. 384, 123376 (2020). https://doi.org/10.1016/J.CEJ.2019.123376

S. Wang, L. Yi, Y. Fang, L. Wang, J. Yao, J. Marek, M. Zhang, J. Appl. Polym. Sci. 138(21), 50465 (2021). https://doi.org/10.1002/APP.50465

I. Yilmaz, M. Gullu, T. Baybura, A.O. Erdogan, Afyon Kocatepe Universitesi Fen ve Muhendislik Bilim Derg. 2(2), 19–35 (2002)

V. Vlad, S. Dumitru, M. Toti, C. Simota, M. Dumitru, Mendeley Data (2020). https://doi.org/10.17632/SDVTD7TBB9.2

K. McLaren, Colour space, colour scales and colour difference, in Colour Physics for Industry, ed. by R. McDonald (Society of Dyers and Colourists, 1987), pp. 106–107

R.E. Wrolstad, D.E. Smith, “Color Analysis”, in Food Analysis, in Food Science Text Series. ed. by S.S. Nielsen (Springer, Cham, 2017), pp.545–555. https://doi.org/10.1007/978-3-319-45776-5_31

A. Agarwal, A. Raheja, T.S. Natarajan, T.S. Chandra, Sens. Actuat. B Chem. 161(1), 1097–1101 (2012). https://doi.org/10.1016/J.SNB.2011.12.027

R. Jiménez, F. Duarte, S. Nuti, J.A. Campo, C. Lodeiro, M. Cano, C. Cuerva, Dye. Pigment. 177, 108272 (2020). https://doi.org/10.1016/J.DYEPIG.2020.108272

B. Liu, L. Wen, K. Nakata, X. Zhao, S. Liu, T. Ochiai, T. Murakami, A. Fujishima, Chem. A Eur. J. 18(40), 12705–12711 (2012). https://doi.org/10.1002/CHEM.201200178

W. Zhang, X. Ji, C. Zeng, K. Chen, Y. Yin, C. Wang, J. Mater. Chem. C 5(32), 8169–8178 (2017). https://doi.org/10.1039/C7TC02077E

Y. Zhang, H. Liu, J. Niu, X. Wang, D. Wu, Appl. Energy 264, 114729 (2020). https://doi.org/10.1016/J.APENERGY.2020.114729

Y. Pu, J. Fang, Coll. Surf. A Physicochem. Eng. Asp. 653, 129889 (2022). https://doi.org/10.1016/J.COLSURFA.2022.129889

L. Ghasemi-Mobarakeh, M.P. Prabhakaran, M. Morshed, M.H. Nasr-Esfahani, S. Ramakrishna, Mater. Sci. Eng. C 30(8), 1129–1136 (2010). https://doi.org/10.1016/j.msec.2010.06.004

X. Wang, H. Zhao, L. Turng, Q. Li, Ind. Eng. Chem. Res. 52(13), 4939–4949 (2013). https://doi.org/10.1021/ie302185e

S.K. Bhullar, D. Rana, H. Lekesiz, A.C. Bedeloglu, J. Ko, Y. Cho, Z. Aytac, T. Uyar, M. Jun, M. Ramalingam, Mater. Sci. Eng. C 81, 334–340 (2017). https://doi.org/10.1016/J.MSEC.2017.08.022

G. Perumal, P.M. Sivakumar, A.M. Nandkumar, M. Doble, Mater. Sci. Eng. C 109, 110527 (2020). https://doi.org/10.1016/J.MSEC.2019.110527

S. Fahimirad, P. Satei, A. Ganji, H. Abtahi, J. Biomater. Sci. Polym. Ed. 34(3), 277–301 (2023). https://doi.org/10.1080/09205063.2022.2116209

P. Stafiej, F. Kung, D. Thieme, M. Czugala, F.E. Kruse, D.W. Schubert, T.A. Fuchsluger, Mater. Sci. Eng. C 71, 764–770 (2017). https://doi.org/10.1016/J.MSEC.2016.10.058

W. Zou, Z. Li, Z. Wang, D. Sun, Wood Mater. Sci. Eng. (2023). https://doi.org/10.1080/17480272.2022.2160657

K. Koenig, N. Balakrishnan, S. Hermanns, F. Langensiepen, G. Seide, Mater. 13(5), 1055 (2020). https://doi.org/10.3390/MA13051055

K. Sukata, H. Takeuchi, M. Shimada, Y. Agari, J. Appl. Polym. Sci. 101(5), 3270–3274 (2006). https://doi.org/10.1002/APP.23715

T.U. Rashid, R.E. Gorga, W.E. Krause, Adv. Eng. Mater. 23(9), 2100153 (2021). https://doi.org/10.1002/ADEM.202100153

F. Croisier, A.S. Duwez, C. Jerome, A.F. Leonard, K.O. van der Werf, P.J. Dijkstra, M.L. Bennink, Acta Biomater. 8(1), 218–224 (2012). https://doi.org/10.1016/J.ACTBIO.2011.08.015

W. Lin, Y. Gowayed, J. Appl. Polym. Sci. 74(10), 2386–2396 (1999). https://doi.org/10.1002/(SICI)1097-4628(19991205)74:10%3c2386::AID-APP6%3e3.0.CO;2-U

J. Ma, T.A. Elmaaty, S. Okubayashi, Autex Res. J. 19(3), 228–235 (2019). https://doi.org/10.1515/aut-2018-0046

B. Veleirinho, M.F. Rei, J.A. Lopes-Da-Silva, J. Polym. Sci. Part B Polym. Phys. 46(5), 460–471 (2008). https://doi.org/10.1002/POLB.21380

C.T. Lim, E.P.S. Tan, S.Y. Ng, Appl. Phys. Lett. 92, 141908 (2008). https://doi.org/10.1063/1.2857478

A. Seeboth, D. Lötzsch, Thermochromic phenomena in polymers. Smithers Rapra Technology, (2008).

R. Kulcar, M. Friskovec, N. Hauptman, A. Vesel, M.K. Gunde, Dyes Pigm. 86(3), 271–277 (2010). https://doi.org/10.1016/j.dyepig.2010.01.014

R.M. Christie, S. Robertson, S. Taylor, Colour Des. Creat. 1(1), 5 (2007)

M. Ledendal, Ph. D Thesis, Heriot-Watt University, School of Textiles and Design, (2015).

L. Johansson, Ph.D. Thesis, Linköping University, Linköping, Sweden, (2006).

T. Homola, AccessScience (McGraw-Hill Education, New York, NY, USA, 2008)

R. Kulcar, M. Klanjseg Gunde, N. Knesaurek, Acta graphica 23(1–2), 25–36 (2012)

C.K. da Silva, D.J. da Silveira Mastrantonio, J.A. Costa, M.G. de Morais, Food Chem. 294, 397–404 (2019). https://doi.org/10.1016/J.FOODCHEM.2019.05.059

W. Mokrzycki, M. Tatol, Mach. Graph. Vis. 20(4), 383–411 (2011)

Acknowledgements

The authors would like to thank to Mehmet Eren Burkay, Burkay Tekstil Co., for providing the thermochromic dye.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 6015 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Duzyer Gebizli, S., Guclu, N., Tiritoglu, M. et al. Reversible Thermochromic Polycaprolactone Nanofibers for Repetitive Usage. Fibers Polym 24, 3393–3403 (2023). https://doi.org/10.1007/s12221-023-00323-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00323-4