Abstract

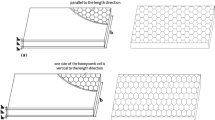

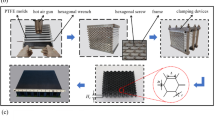

Sandwich structure is widely used in aviation field due to their high out-of-plane compression properties, shear properties, and outstanding energy absorption characteristics. During the forming process, the aluminum honeycomb will form double cell wall because of adhesive layers. The double cell wall has a great influence on the compressive properties, but there are only few researches on it. In this paper, the influence of double cell wall on the compression performance of sandwich structure was studied, and the failure process of double cell was analyzed from micro perspective. Finite element models of aluminum honeycomb and sandwich structure were established in the software ABAQUS. Moreover, the unit model including double cell wall and single cell wall was also established, and then the effectiveness of the simulation was verified by experiments. The compression experiment was carried out on the universal test machine with sandwich structure and the test speed was set as 2 mm/min. The results show that the failure occurs from one end when the aluminum honeycomb faces with flat compression load alone, while the failure of the sandwich structure starts from the middle of the core. The adhesive layer in the double cell wall is subjected to both compressive stress and tensile stress, and the failure occurs first in tension position. Then, the effects of double cell wall different bonding parameters and different panel layering angles on the compressive properties of the structure were studied. The results show that the structural compression performance increases slowly after the bonding length reaches 4 mm, and the bonding thickness less than 0.1 mm has little influence on the compression performance. The fiber orientation of the panel close to the core can be designed to be 90° which is parallel to the double cell wall, which can effectively improve the flat compression performance.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during this study are available from the corresponding author on reasonable request.

References

D. Asprone, F. Auricchio, C. Menna, S. Morganti, A. Prota, A. Reali, Statistical finite element analysis of the buckling behaviour of honeycomb structures. Compos Struct. 105, 240–255 (2013)

M.M. Awd Allah, M.A. Abd El-baky, M.A. Hassan, A. Shaker, Crashworthiness performance of Thin-walled Glass/epoxy square tubes with circular cutouts: an experimental study. Fibers Polym 23, 3268–3281 (2022)

M.A.A. El-baky, M.M.A. Allah, M. Kamel, W. Abdel-Aziem, Fabrication of Glass/Jute hybrid composite over wrapped Aluminum cylinders: an advanced material for automotive applications. Fibers Polym 24, 143–155 (2023)

K. Abd El-Aziz, D.A. Hegazy, M.A. Abd El-baky, Impact of Montmorillonite clay on energy absorption capability of glass/epoxy composite tubes: an experimental study. Fibers Polym 23, 2284–2298 (2022)

M.A. Abd El-baky, D.A. Hegazy, M.A. Hassan, Advanced thin-walled composite structures for energy absorption applications. Appl Compos Mater 29, 1195–1233 (2022)

Z.H. Kamaruddin, R. Jumaidin, Z.H. Kamaruddin, M.R.M. Asyraf, M.R. Razman, T. Khan, Effect of cymbopogan citratus fibre on physical and impact properties of thermoplastic cassava starch/palm wax composites. Polymers 15(10), 2364 (2023)

M.R.M. Asyraf, T. Khan, A. Syamsir, A.B.M. Supian, Synthetic and natural fiber-reinforced polymer matrix composites for advanced applications. Materials. 15(17), 6030 (2022)

M.K. Cvitkovich, W.C. Jackson, Compressive failure mechanisms in composite sandwich structures. J Am Helicopter Soc. 44(4), 260–268 (1999)

C.G. Kim, E. Jun, Impact resistance of composite laminated sandwich plates. J Compos Mater. 26, 2247–2261 (1992)

G. Zhou, M. Hill, J. Loughlan, N. Hookham, Damage characteristics of composite honeycomb sandwich panels in bending under quasi-static loading. J Sandw Struct Mater. 8(1), 55–90 (2006)

S. Abrate, Localized impact on sandwich structures with laminated facings. Appl Mech Rev. 50(2), 69–82 (1997)

T.E. Lacy, Y. Hwang, Numerical modeling of impact-damaged sandwich composites subjected to compression-after-impact loading. Compos Struct. 61, 115–128 (2003)

L. Aktay, A.F. Johnson, B.H. Kroplin, Numerical modelling of honeycomb core crush behaviour. Eng Fract Mech. 75, 2616–2630 (2008)

A. Wilbert, W.-Y. Jang, S. Kyriakides, J.F. Floccari, Buckling and progressive crushing of laterally loaded honeycomb. Int J Solids Struct. 48, 803–816 (2011)

Xu. Shanqing, J.H. Beynon, D. Ruan, Lu. Guoxing, Experimental study of the out-of-plane dynamic compression of hexagonal honeycombs. Compos Struct. 94, 2326–2336 (2012)

W. Miller, C.W. Smith, K.E. Evans, Honeycomb cores with enhanced buckling strength. Cmpos Struct. 93, 1072–1077 (2011)

F. Mujika, J. Pujana, M. Olave, On the determination of out-of-plane elastic properties of honeycomb sandwich panels. Polym Test. 30, 222–228 (2011)

L. Liu, P. Meng, H. Wang, Z. Guan, The flatwise compressive properties of Nomex honeycomb core with debonding imperfections in the double cell wall. Compos. B Eng. 76, 122–132 (2015)

L. Liu, H. Wang, Z. Guan, Experimental and numerical study on the mechanical response of Nomex honeycomb core under transverse loading. Compos. Struct. 121, 304–314 (2015)

H. Feng, L. Liu, Qi. Zhao, Experimental and numerical investigation of the effect of entrapped air on the mechanical response of Nomex honeycomb under flatwise compression. Compos. Struct. 182, 617–627 (2017)

S. Wei, Z. Guo, H. Shi, G.B. Chai, Y. Li, Y. Luan, Compression properties of carbon fiber reinforced polymer grid sandwich structure. J Reinforced Plastics Composites (2022). https://doi.org/10.1177/07316844221140558

M.R.M. Asyraf, A. Syamsir, H. Bathich, Z. Itam, A.B.M. Supian, S. Norhisham, N.M. Nurazzi, T. Khan, M.Z. Rashid, Effect of fibre layering sequences on flexural creep properties of kenaf fibre-reinforced unsaturated polyester composite for structural applications. Fibers Polym 23, 3232–3240 (2022)

M.R.M. Asyraf, A. Syamsir, N.M. Zahari, A.B.M. Supian, F. Usman, Z. Itam, Effect of stacking sequence on long-term creep performance of pultruded GFRP composites. Polymers 14(19), 4064 (2022)

Y. Aminanda, B. Castanié, J.-J. Barrau, P. Thevenet, Experimental analysis and modelling of the crushing of honeycomb cores. Appl Compos Mater. 12, 213–227 (2005)

M. Giglio, A. Gilioli, A. Manes, A numerical investigation on significant parameters influencing the flatwise compressive behaviour of a Nomex Honeycomb. Procedia Engineering. 10, 3441–3446 (2011)

A. Karakoç, K. Santaoja, J. Freund, Simulation experiments on the effective in-plane compliance of the honeycomb materials. Compos. Struct. 96, 312–320 (2013)

R. Roy, S.-J. Park, J.-H. Kweon, J.-H. Choi, Characterization of Nomex honeycomb core constituent material mechanical properties. Compos. Struct. 117, 255–266 (2014)

D. Asprone, F. Auricchio, C. Menna, S. Morganti, A. Prota, A. Reali, Statistical finite element analysis of the buckling behavior of honeycomb structures. Compos Struct. 105, 240–255 (2013)

A. Syamsir, L.-W. Ean, M.R.M. Asyraf, A.B.M. Supian, E. Madenci, Y.O. Özkılıç, C. Aksoylu, Recent advances of GFRP composite cross arms in energy transmission tower: a short review on design improvements and mechanical properties. Materials. 16(7), 2778 (2023)

Test method for flatwise compression properties of sandwich constructions or cores (GB/T 1453). 2005

R.K. Fathers, J.M. Gattas, Z. You, Quasi-static crushing of eggbox, cube, and modified cube foldcore sandwich structures. Int J Mech Sci. 101–102, 421–428 (2015)

NPCS Board of Consultants & Engineers. Phenolic resins technology handbook. New Delhi: NIIR Project Consultancy Services; 2007.

Y. Tao, M. Chen, Y. Pei, D. Fang, Strain rate effect on mechanical behavior of metallic honeycombs under out-of-plane dynamic compression. J Appl Mech. 82, 021007 (2015)

A. Asm, L. Ruan Dong, B.A. Guoxing, Finite element analysis of aluminum honeycombs subjected to dynamic indentation and compression loads. Materials. 9(1), 162 (2016)

H. Zhou, X. Zhang, X. Wang, Y. Wang, T. Zhao, Response of foam concrete-filled aluminum honeycombs subject to quasistatic and dynamic compression. Compos. Struct. 239, 112025 (2020)

Acknowledgements

This work was supported by National Natural Science Foundation of China (52275449). The authors are grateful for this financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no relevant financial or non-financial interests to disclose.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, L., Ni, C., Liu, G. et al. Analysis of Honeycomb and Sandwich Structure Compression Property and the Damage of Double Cell Wall. Fibers Polym 24, 3245–3260 (2023). https://doi.org/10.1007/s12221-023-00289-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00289-3