Abstract

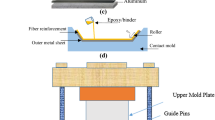

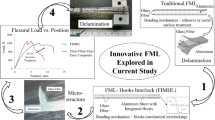

Fiber metal laminates (FMLs) are made by sandwiching a fiber-reinforced composite between thin layers of metals. FMLs are the most modern materials utilized in automotive and aerospace manufacture because of their superior mechanical behavior when compared to conventional metallic alloys. In the current work, the effect of hybridization between jute-reinforced composites and other fabrics on the mechanical properties of the designed FMLs was experimentally assessed under various tests, including tension, flexural, in-plane shear, interlaminar shear, and bearing tests. Aluminum alloy 1050 (AA 1050) was used as a metal component in the designed FMLs, while the composite components are jute (J), glass (G), aramid (A), carbon (C), and basalt (B) fabrics. To ensure good adhesion between Al-sheets and composite laminates, Al-sheets underwent both mechanical and chemical treatments. The intended FMLs were prepared via hand lay-up and compression casting techniques. The designed stacking sequences were 8 J, 2G/4J/2G, 2A/4J/2A, 2C/4J/2C, and 2B/4J/2B. According to the experimental results compared with the 8 J specimen, the 2G/4J/2G specimen presents maximum flexural strength, flexural modulus, and interlaminar shear strength with an improvement percent of 51.51, 212.33, and 15.72%, respectively. On top of that, the 2A/4J/2A specimen introduces maximum tensile failure strain and tensile toughness modulus with an enhancement percent of, respectively, 21.56 and 116.56%, while the 2C/4J/2C specimen introduces extreme tensile strength, tensile modulus, flexural strain, in-plane shear strength, and bearing strength with an upgrading percent of 181.91, 111.86, 21.24, 26.38, and 60.94%, respectively.

Similar content being viewed by others

Data availability statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- FMLs:

-

Fiber metal laminates

- AA 1050:

-

Aluminum alloy 1050

- Al:

-

Aluminum

- J:

-

Jute fabrics

- G:

-

Glass fabrics

- A:

-

Aramid fabrics

- C:

-

Carbon fabrics

- B:

-

Basalt fabrics

- F:

-

Flax fabrics

- K:

-

Kenaf fabrics

- CAFRALL:

-

Laminates made from carbon and flax fiber-reinforced aluminum

- CAKRALL:

-

Laminates made from carbon and Kenaf fiber-reinforced aluminum

- EFFMLs:

-

Eco-friendly fiber metal laminates

- HCl:

-

Hydrochloric acid

- NaOH:

-

Sodium hydroxide

- UTM:

-

Universal testing machine

- \({\sigma }_{ult}\) :

-

Ultimate tensile strength

- \({E}_{app}\) :

-

Apparent tensile modulus

- \({U}_{T}\) :

-

Toughness modulus

- \({\sigma }_{fl}\) :

-

Flexural strength

- \({\varepsilon }_{fl}\) :

-

Flexural strain

- \({E}_{fl}\) :

-

Flexural modulus

- \({\tau }_{12}\) :

-

In-plane shear stress

- ILSS:

-

Interlaminar shear strength

- SBS:

-

Short beam shear

- \({\sigma }_{b}\) :

-

Bearing strength

References

X. Li, X. Zhang, Y. Guo, V.P.W. Shim, J. Yang, G.B. Chai, Int. J. Impac. Eng. 114, 32 (2018)

M. Megahed, M.A. Abd El-baky, A.M. Alsaeedy, A.E. Alshorbagy, Compos. Pt B: Eng., 176, 107277 (2019)

M.R. Sanjay, P. Madhu, M. Jawaid, P. Senthamaraikannan, S. Senthil, S. Pradeep, J. Cleaner Prod. 172, 566 (2018)

N. Karthi, K. Kumaresan, S. Sathish, S. Gokulkumar, L. Prabhu, N. Vigneshkumar, Mater. Tod. Proceed. 27, 2828 (2020)

D. Gon, K. Das, P. Paul, S. Maity, Int. J. Text. Sci. 1, 84 (2013)

H. Alshahrani, T. A. Sebaey, M. M. Awd Allah, and M. A. Abd El-baky, J. Compos. Mater. (2023)

V. Mishra, S. Biswas, Proced. Eng. 51, 561 (2013)

K.S. Ahmed, S. Vijayarangan, J. Appl. Polym. Sci. 104, 2650 (2007)

A. Mache, A. Deb, N. Gupta, Polym. Compos. 41, 1796 (2019)

P. Amuthakkannan, V. Manikandan, M. Uthayakumar, J. Advanc. Microsc. Res. 9, 44 (2014)

V. Ganesan, B. Kaliyamoorthy, J. Nat. Fib. 19, 1990 (2020)

S.I. Mavani, N.M. Mehta, P.H. Parsania, J. Appl. Polym. Sci. 106, 1228 (2007)

M.A. Attia, M.A. Abd El-Baky, M.A. Hassan, T.A. Sebaey, E. Mahdi, Poly. Compos., 39, E2245 (2018)

M.A.A. El-baky, M.M.A. Allah, M. Kamel, W. Abdel-Aziem, Fib. Polym. (2023)

R.E. Farsani, S.M.R. Khalili, V. Daghigh, Int. J. Damag. Mech. 23, 729 (2013)

D. Gunwant, Int. J. Res. Appl. Sci. Eng. Tech. 6, 1391 (2018)

N.M. Ishak, D. Sivakumar, M.R. Mansor, J. Brazil. Soc. Mech. Sci. Eng, 40 (2018)

I. Mohammed, A.A. Talib, M.T.H. Sultan, M. Jawaid, A.H. Ariffin, S. Saadon, Bio. Res. 13, 2022–2034 (2018)

N. Zareei, A. Geranmayeh, R. Eslami-Farsani, Polym. Test. 75, 205 (2019)

N.L. Feng, S. DharMalingam, K.A. Zakaria, M.Z. Selamat, J. Sand. Struct. Mater. 21, 2440 (2017)

M.A. Abd El-Baky, A.E. Alshorbagy, A.M. Alsaeedy, M. Megahed, J. Nat. Fib., 19, 303 (2020)

M. A. Abd El‐baky and M. A. Attia, Polym. Compos., 41, 4130 (2020)

Z. Boufaida, L. Farge, S. André, Y. Meshaka, Compos. Pt A Appl. Sci. Manufact. 75, 28 (2015)

M. Megahed, D.E. Tobbala, M.A.A. El-baky, Polym. Compos. 42, 271 (2020)

M.A.A. El-Baky, M.M.A. Allah, M. Kamel, W. Abd-Elaziem, Sci. Rep. 12, 21101 (2022)

M.I.A. El Aal, M.M. Awd Allah, M.A. Abd El‐baky, Polym. Compos., (2023)

M.M. Awd Allah, A. Shaker, M.A. Hassan, M.A. Abd El‐baky, Polym. Compos. (2022)

H. Alshahrani, T.A. Sebaey, M.M. Awd Allah, M.A. Abd El‐baky, Polym. Compos. (2022)

H. Alshahrani, T.A. Sebaey, M.M. Awd Allah, M.A. Abd El-baky, J. Compos. Mater., 57, 1579 (2023)

H. Alshahrani, T.A. Sebaey, M.M. Awd Allah, M.A. Abd El-baky, J. Compos. Mater. (2022)

M.A.A. El-Baky, M.M.A. Allah, M. Kamel, W. Abd-Elaziem, Sci. Rep. 12, 21097 (2022)

M. Megahed, M.A. Abd El-baky, A.M. Alsaeedy, A.E. Alshorbagy, Fib. Polym., 21, 840 (2020)

M. Megahed, M.A. Abd El-baky, A.M. Alsaeedy, A.E. Alshorbagy, Fib. Polym., 22, 1366 (2021)

A.I. Selmy, M.A. Abd El-baky, D.A. Hegazy, J. Thermop. Compos. Mater., 32, 267 (2018)

M.M. Awd Allah, M.A. Abd El-baky, M.A. Hassan, A. Shaker, Fib. Polym., 23, 3268 (2022)

S. Dhar Malingam, F.A. Jumaat, L.F. Ng, K. Subramaniam, A.F. Ab Ghani, Advanc. Polym. Tech., 37, 2385 (2018)

G.R. Rajkumar, M. Krishna, H.N. Narasimhamurthy, Y.C. Keshavamurthy, J.R. Nataraj, Proced. Mater. Sci. 5, 60 (2014)

H. Li, Y. Xu, X. Hua, C. Liu, J. Tao, Compos. Struct. 187, 354 (2018)

N.R.J. Hynes, N.J. Vignesh, J.T.W. Jappes, P.S. Velu, C. Barile, M.A. Ali, M.U. Farooq, C.I. Pruncu, Compos. Sci. Tech., 221 (2022)

Y. Hu, Y. Zhang, X. Fu, G. Hao, W. Jiang, Compos. Struct., 229 (2019)

Acknowledgements

The author would like to thank Prince Sultan University for their support. The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work, under the Research Groups Funding program grant code (NU/RG/SERC/12/8).

Funding

This study was funded by Najran University, NU/RG/SERC/12/8, Hassan Alshahrani.

Author information

Authors and Affiliations

Contributions

MMAA did writing the original copy, drawing the curves, analysis of data results, and preparing the final revision. DAH was involved in preparing the response to the reviewer’s comments, revising the English quality, and preparing the final revision. HA prepared the response to the reviewer’s comments and the final revision. TAS prepared the response to the reviewer’s comments, revised the English quality, and prepared the final revision. MAAE contributed to idea, experimental work, analysis of data results, supervision, preparing the final revision.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Allah, M.M.A., Hegazy, D.A., Alshahrani, H. et al. Fiber Metal Laminates Based on Natural/Synthesis Fiber Composite for Vehicles Industry: an Experimental Comparative Study. Fibers Polym 24, 2877–2889 (2023). https://doi.org/10.1007/s12221-023-00281-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00281-x