Abstract

Shape memory epoxy polymer reinforced by single-ply weave fabric (SMEP-W) possesses high specific stiffness, good foldability, and satisfactory shape memory capability. These advantages make them promising materials for deployable space structures and increasingly attract research interests. Understanding the influence of weave structures on static and dynamic mechanical properties is crucial to structural design and mechanical response prediction. In this paper, a recently developed SMEP-W was prepared. The static shear experiments were conducted through modified shear test fixtures, and the stress field under static shear load was simulated through a multi-scale numerical modelling method. The dynamic mechanical analysis was carried out to evaluate the shape memory capability. SMEP-W shows nonlinear mechanical behavior under in-plane shear load, especially for the one with less thread count. The increase in the number of threads enhances the constraints between warp yarns and weft yarns, leading to an increase in shear modulus and reducing the scattering of static mechanical properties. The stress distribution on the yarns has the characteristic of center symmetry. High-stress regions appear on the overlapping surface of the crossover regions. Compared with shape memory epoxy polymer (SMEP), the glass transition temperature and damping coefficient of SMEP-W are significantly reduced, and the stiffness is remarkably enhanced. The difference in thread count between warp direction and weft direction does not notably affect the glass transition temperature and tan δ, but has a remarkable influence on the storage modulus. The present work could provide basic observation for understanding the influence of thread count on the shear mechanical properties and dynamic mechanical properties of SMEP-W.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Wang K, Jia Y-G, Zhao C, Zhu XX. Multiple and two-way reversible shape memory polymers: Design strategies and applications. Prog Mater Sci 2019;105:100572. https://doi.org/10.1016/j.pmatsci.2019.100572.

N. Zheng, G. Fang, Z. Cao, Q. Zhao, T. Xie, High strain epoxy shape memory polymer. Polym. Chem. 6, 3046–3053 (2015). https://doi.org/10.1039/C5PY00172B

J. Gao, W. Chen, B. Yu, P. Fan, B. Zhao, J. Hu, D. Zhang, G. Fang, F. Peng, Effect of temperature on the mechanical behaviours of a single-ply weave-reinforced shape memory polymer composite. Compos. Part B Eng. 159, 336–345 (2019). https://doi.org/10.1016/j.compositesb.2018.09.029

Guo A, Kong D, Zhou X, Kong H, Qu P, Wang S, Wang H, Hu Y. Method for preparing damage-resistant 3D-printed ceramics via interior-to-exterior strengthening and toughening. Addit. Manuf. 2022;60:103272. https://doi.org/10.1016/j.addma.2022.103272.

Guo S, Wang M, Sui S, Li J, Chen H, Hao X, Zhao X, Lin X. Research on optimizing strength and ductility of HfNbTaZr dual-phase high-entropy alloy by tuning chemical short-range order. Int. J. Refract Met. Hard Mater. 2022;108:105942. https://doi.org/10.1016/j.ijrmhm.2022.105942.

Y. Qian, J. Shi, H. Sun, Y. Chen, Q. Wang, Vector solid texture synthesis using unified RBF-based representation and optimization. Vis. Comput. (2022). https://doi.org/10.1007/s00371-022-02541-y

Luo L, Zhang F, Leng J. Multi-performance shape memory epoxy resins and their composites with narrow transition temperature range. Compos Sci Technol 2021;213:108899. https://doi.org/10.1016/j.compscitech.2021.108899.

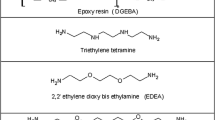

M.J. Jo, H. Choi, G.H. Kim, W.-R. Yu, M. Park, Y. Kim, J. Park, J. Youk, Preparation of epoxy shape memory polymers for deployable space structures using flexible diamines. Fibers. Polym. 19, 1799–1805 (2018). https://doi.org/10.1007/s12221-018-8549-5

J. Hu, W. Chen, P. Fan, J. Gao, G. Fang, Z. Cao, G. Fang, Z. Cao, D. Peng, Uniaxial tensile tests and dynamic mechanical analysis of satin weave reinforced epoxy shape memory polymer composite. Polym. Test 64, 235–241 (2017). https://doi.org/10.1016/j.polymertesting.2017.09.038

P. Turner, T. Liu, X. Zeng, K. Brown, Three-dimensional woven carbon fibre polymer composite beams and plates under ballistic impact. Compos. Struct. 185, 483–495 (2018). https://doi.org/10.1016/j.compstruct.2017.10.091

Guo L, Liao F, Xu Y, Wang T, Yang C, Yuan J. Experimental method and failure mechanisms investigation for out-of-plane shear fatigue behavior of 3D woven composites. Int. J. Fatigue 2020;134:105501. https://doi.org/10.1016/j.ijfatigue.2020.105501.

R. Mishra, J. Militky, N. Gupta, R. Pachauri, B.K. Behera, Modelling and simulation of earthquake resistant 3D woven textile structural concrete composites. Compos. Part B Eng. 81, 91–97 (2015). https://doi.org/10.1016/j.compositesb.2015.07.008

Thakre P, Lagoudas D, Zhu J, Barrera E, Gates T. Processing and Characterization of Epoxy/SWCNT/Woven Fabric Composites. 47th AIAAASMEASCEAHSASC Struct. Struct. Dyn. Mater. Conf. 14th AIAAASMEAHS Adapt. Struct. Conf. 7th, Newport, Rhode Island: American Institute of Aeronautics and Astronautics; 2006. https://doi.org/10.2514/6.2006-1857.

S. Jiang, A. Greiner, S. Agarwal, Short nylon-6 nanofiber reinforced transparent and high modulus thermoplastic polymeric composites. Compos. Sci. Technol. 87, 164–169 (2013). https://doi.org/10.1016/j.compscitech.2013.08.011

S. Wang, J. Zhang, A. Guo, S. Liang, Buckling performance of co-cured and stiffened composite structure with embedded multilayer damping membranes. Polym. Compos. 43, 7403–7419 (2022). https://doi.org/10.1002/pc.26821

I. Goda, Z. Zubair, G. L’Hostis, J.-Y. Drean, Design and characterization of 3D multilayer woven reinforcements shape memory polymer composites. J. Compos. Mater. 55, 653–673 (2021). https://doi.org/10.1177/0021998320958178

T. Gereke, O. Döbrich, M. Hübner, C. Cherif, Experimental and computational composite textile reinforcement forming: a review. Compos. Part Appl. Sci. Manuf. 46, 1–10 (2013). https://doi.org/10.1016/j.compositesa.2012.10.004

L. Santo, F. Quadrini, P.L. Ganga, V. Zolesi, Mission BION-M1: Results of RIBES/FOAM2 experiment on shape memory polymer foams and composites. Aerosp. Sci Technol 40, 109–114 (2015). https://doi.org/10.1016/j.ast.2014.11.008

L. Puig, A. Barton, N. Rando, A review on large deployable structures for astrophysics missions. Acta. Astronaut. 67, 12–26 (2010). https://doi.org/10.1016/j.actaastro.2010.02.021

Liu Y, Du H, Liu L, Leng J. Shape memory polymers and their composites in aerospace applications: a review. Smart Mater. Struct. 2014;23:023001. https://doi.org/10.1088/0964-1726/23/2/023001.

Lu H, Li Z, Qi X, Xu L, Chi Z, Duan D, Islam M, Wang W, Jin X, Zhu Y, Fu Y, Cui L, Zhuang Y, Dong Y. Flexible, electrothermal-driven controllable carbon fiber/poly(ethylene-co-vinyl acetate) shape memory composites for electromagnetic shielding. Compos. Sci. Technol. 2021;207:108697. https://doi.org/10.1016/j.compscitech.2021.108697.

J. Gao, W. Chen, P. Fan, B. Zhao, J. Hu, D. Zhang, Q. Fang, F. Peng, Experimental determination of mechanical properties of a single-ply broken twill 1/3 weave reinforced shape memory polymer composite. Polym. Test 69, 100–106 (2018). https://doi.org/10.1016/j.polymertesting.2018.05.002

P. Qu, Y. Wan, C. Bao, Q. Sun, G. Fang, J. Takahashi, A new numerical method for the mechanical analysis of chopped carbon fiber tape-reinforced thermoplastics. Compos. Struct. 201, 857–866 (2018). https://doi.org/10.1016/j.compstruct.2018.06.110

G. Fang, P. Qu, Z. Cao, F. Shi, Mechanical analysis of woven composites through experimental investigation and multiscale numerical simulation. Fibers Polym. 23, 1440–1453 (2022). https://doi.org/10.1007/s12221-022-4061-z

Qu P, Wan Y, Fang G, Guo A, Liu G, Takahashi J. A novel heterogeneous-particle model based on peridynamics for flexural mechanical properties of randomly oriented fiber reinforced composites. Compos. Part B Eng. 2022;243:110140. https://doi.org/10.1016/j.compositesb.2022.110140.

Wang B, Fang G, Wang H, Liang J, Dai F, Meng S. Uncertainty modelling and multiscale simulation of woven composite twisted structure. Compos. Sci. Technol. 2022;217:109118. https://doi.org/10.1016/j.compscitech.2021.109118.

Ying Z, Pan X, Wu Z, Pan Z, Cheng X. Effect of the micro-structure on the compressive failure behavior of three-dimensional orthogonal woven composites. Compos Struct 2022;297:115892. https://doi.org/10.1016/j.compstruct.2022.115892.

Kim D-H, Kim S-W, Lee I. Evaluation of curing process-induced deformation in plain woven composite structures based on cure kinetics considering various fabric parameters. Compos Struct 2022;287:115379. https://doi.org/10.1016/j.compstruct.2022.115379.

Zhou G, Sun Q, Meng Z, Li D, Peng Y, Zeng D, Su X. Experimental investigation on the effects of fabric architectures on mechanical and damage behaviors of carbon/epoxy woven composites. Compos. Struct. 2021;257:113366. https://doi.org/10.1016/j.compstruct.2020.113366.

Zhou G, Sun Q, Li D, Meng Z, Peng Y, Zeng D, Su X. Effects of fabric architectures on mechanical and damage behaviors in carbon/epoxy woven composites under multiaxial stress states. Polym. Test 2020;90:106657. https://doi.org/10.1016/j.polymertesting.2020.106657.

Wang Y, Zhou Y, Jin C. An analytical nonlinear model for plain-woven composites under off-axis loads. Compos. Struct. 2022;296:115905. https://doi.org/10.1016/j.compstruct.2022.115905.

Xiao Y, Zhang X, Ghosh S. Parametrically-upscaled continuum damage mechanics (PUCDM) model for plain weave woven composites: part I model development. Compos. Struct. 2022;296:115825. https://doi.org/10.1016/j.compstruct.2022.115825.

Nasri M, Abbassi F, Garnier C, Labanieh AR, Dalverny O, Zghal A. Analysis of woven fabrics forming through a comparison between discrete elastic and hypoelastic approaches based on mesoscale structure. Compos. Struct. 2022;284:115149. https://doi.org/10.1016/j.compstruct.2021.115149.

J. Leng, X. Lan, Y. Liu, S. Du, Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 56, 1077–1135 (2011). https://doi.org/10.1016/j.pmatsci.2011.03.001

Zhao Y, Song J, Wen W, Cui H, Li C, Liu S. Thermo-mechanical behaviors of 2.5D shallow straight-link-shaped woven composites under the warp direction fatigue loading at room and elevated temperatures. Compos. Struct. 2022;289:115489. https://doi.org/10.1016/j.compstruct.2022.115489.

Z. Zhao, X. Chen, X. Wang, Deformation behavior of woven glass/epoxy composite substrate under thermo-mechanical loading. Mater. Des. 82, 130–135 (2015). https://doi.org/10.1016/j.matdes.2015.05.048

Z. Murčinková, P. Postawa, J. Winczek, Parameters influence on the dynamic properties of polymer-matrix composites reinforced by fibres, particles, and hybrids. Polymers 14, 3060 (2022). https://doi.org/10.3390/polym14153060

M.N.M. Azlin, S.M. Sapuan, M.Y.M. Zuhri, E.S. Zainudin, R.A. Ilyas, Thermal stability, dynamic mechanical analysis and flammability properties of woven kenaf/polyester-reinforced polylactic acid hybrid laminated composites. Polymers 14, 2690 (2022). https://doi.org/10.3390/polym14132690

Nandi P, Das D. Mechanical, thermo-mechanical and biodegradation behaviors of green-composites prepared from woven structural nettle (Girardinia diversifolia) reinforcement and poly(lactic acid) fibers. Ind. Crops. Prod. 2022;175:114247. https://doi.org/10.1016/j.indcrop.2021.114247.

Ke J, Gao J, Wu Z, Xiang Z, Hu X. Vari-stiffness characteristics of a 3D SMA hybrid basalt woven composite. Compos. Struct. 2022;285:115192. https://doi.org/10.1016/j.compstruct.2022.115192.

Han M-W, Kim M-S, Ahn S-H. Shape memory textile composites with multi-mode actuations for soft morphing skins. Compos. Part B Eng. 2020;198:108170. https://doi.org/10.1016/j.compositesb.2020.108170.

Zubair Z, L’Hostis G, Goda I. Electrical activation and shape recovery control of 3D multilayer woven shape memory polymer composite incorporating carbon fibers. Mater. Lett. 2021;291:129511. https://doi.org/10.1016/j.matlet.2021.129511.

Sevenois RDB, Van Paepegem W. Fatigue damage modeling techniques for textile composites: review and comparison with unidirectional composite modeling techniques. Appl. Mech. Rev. 2015;67. https://doi.org/10.1115/1.4029691.

J. Hu, W. Chen, P. Fan, J. Gao, G. Fang, Z. Cao, F. Peng, Epoxy shape memory polymer (SMP): material preparation, uniaxial tensile tests and dynamic mechanical analysis. Polym. Test 62, 335–341 (2017). https://doi.org/10.1016/j.polymertesting.2017.07.001

W. Chen, G. Fang, Y. Hu, An experimental and numerical study of flattening and wrapping process of deployable composite thin-walled lenticular tubes. Thin-Walled Struct. 111, 38–47 (2017). https://doi.org/10.1016/j.tws.2016.11.009

P. Fan, W. Chen, B. Zhao, J. Hu, J. Gao, G. Fang, F. Peng, Formulation and numerical implementation of tensile shape memory process of shape memory polymers. Polymer 148, 370–381 (2018). https://doi.org/10.1016/j.polymer.2018.06.054

Y. Hu, W. Chen, J. Gao, J. Hu, G. Fang, F. Peng, A study of flattening process of deployable composite thin-walled lenticular tubes under compression and tension. Compos. Struct. 168, 164–177 (2017). https://doi.org/10.1016/j.compstruct.2017.02.029

D4255/D4255M-15a A. Standard test method for in-plane shear properties of polymer matrix composite materials by the rail shear method 2015.

P. Qu, X. Guan, Y. Jia, S. Lou, J. Nie, Effective elastic properties and stress distribution of 2D biaxial nonorthogonally braided composites. J. Compos Mater. 46, 997–1008 (2012). https://doi.org/10.1177/0021998311413684

Z. Xia, Y. Zhang, F. Ellyin, A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 40, 1907–1921 (2003). https://doi.org/10.1016/S0020-7683(03)00024-6

Qu P, Sun X, Ping L, Zhang D, Jia Y. A new numerical model for the analysis on low-velocity impact damage evolution of carbon fiber reinforced resin composites. J. Appl. Polym. Sci. 2017;134. https://doi.org/10.1002/app.44374.

P. Qu, X. Sun, X. Guan, Y. Mu, Y. Jia, Effect of interlaminar toughness on the low-velocity impact damage in composite laminates. Polym. Compos. 37, 1085–1092 (2016). https://doi.org/10.1002/pc.23270

M. Elices, G.V. Guinea, J. Gómez, J. Planas, The cohesive zone model: advantages, limitations and challenges. Eng. Fract Mech. 69, 137–163 (2002). https://doi.org/10.1016/S0013-7944(01)00083-2

M. Fiolka, A. Matzenmiller, On the resolution of transverse stresses in solid-shells with a multi-layer formulation. Commun. Numer. Methods Eng. 23, 313–326 (2007). https://doi.org/10.1002/cnm.908

C. Medina, C. Canales, C. Arango, P. Flores, The influence of carbon fabric weave on the in-plane shear mechanical performance of epoxy fiber-reinforced laminates. J. Compos. Mater. 48, 2871–2878 (2014). https://doi.org/10.1177/0021998313503026

M. Alizadeh, F. Lohrasby, R. Khajavi, N. Kordani, H.R. Baharvandi, M. Rezanejad, Studying the mechanical properties of composites made of Kenaf-Nylon 66 fabric, silica nanoparticles, and epoxy resin. Polym. Compos. 37, 674–683 (2016). https://doi.org/10.1002/pc.23224

Acknowledgements

Financial supports from the National Natural Science Foundation of China (51573094), the Doctor Scientific Research Fund of Liaocheng University (3180500), Innovation and Entrepreneurship Training Plan for College Students of Liaocheng University (CXCY2021163, CXCY2021110) and the Postdoctoral Science Foundation of China (2020M682117) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qu, P., Fang, G., Kong, H. et al. Effect of Thread Count on the Shear Mechanical Properties and Dynamic Mechanical Properties of Shape Memory Polymer Reinforced by Single-Ply Weave Fabric. Fibers Polym 24, 3299–3317 (2023). https://doi.org/10.1007/s12221-023-00269-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00269-7