Abstract

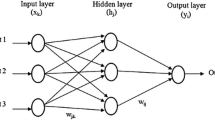

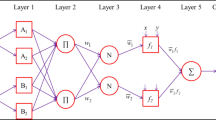

In this article, we intend to use a novel tool in computational intelligence to model the effect of the cotton fibre tensile properties on the fabric wrinkle appearance. For this purpose, two groups of cotton fibres were provided in dry and wet conditions. In both groups, the linear density, tensile strength and breaking elongation of the fibres were considered as important tensile parameters. These parameters were measured in the laboratory for various cotton fibres. The wrinkle degree of the fabric samples manufactured by these fibres was ratted objectively, by the method based on the narrow optical technique. Then, were developed three fuzzy neural network modelling as type1, type2 and polynomial type2. In mentioned models, the cotton fibre linear density, tensile strength and breaking elongation parameters of the fibres were the input parameters, and the wrinkle degree of cotton fabrics was considered as output. The experimental results show the tensile properties of the cotton fibres are increased with the wetting process. Based on the modelling, there is a nonlinear relation between output and input parameters. Second, the wrinkle grade parameter was affected due to the wetting of cotton fibres. According to this results, the wrinkle grade of the fabrics is related to the fibre linear density and tensile parameters. In modeling, three models based on the type 1, type 2 and type 2-nomial fuzzy neural network were developed. Comparisons of the modelling and experimental results show the type2-nominal fuzzy model with accuracy greater than 98.8% and error value smaller than of 0.08% can predict more accuracy amongst three developed models.

Similar content being viewed by others

Data availability statement

Data “available on request” by email.

References

H. Garg, J. Mohanty, P. Gupta, A. Das, B. Tripathi, B. Kumar, Mater. Chem. Phys. (2023). https://doi.org/10.1016/j.matchemphys.2022.126952

T. Karthik, R. Rathinamoorthy, R. Murugan, Ind. Text (2011). https://doi.org/10.1177/1528083711427481

C.W.M. Yuen, C.W. Kan, Fiber. Polym 7, 139 (2006)

M.S. Hesarian, J. Tavoosi, CompLex (2022). https://doi.org/10.1155/2022/2401736

Y. Can, M. Akaydin, Y. Turhan, E. Ay, IJFTR 34, 183 (2009)

D. Atalie, A. Ferede, N. Ezazshahabi, Fash. Text 6, 1 (2019)

A. Abrishami, F. Mousazadeghan, G. Kipchirchir, J. Text. Inst 110, 690 (2019)

B. Xu, J.A. Reed, Text. Res. J 86, 123 (1995)

B. Xu, D.F. Cuminato, Text. Res. J 68, 900 (1998)

J. Amirbayat, M.J. Alagha, J. Text. Inst 87, 349 (1996)

H. Yan, Tex. Res. J 72, 863 (2002)

M.S. Hesarian, J. Text. Inst 101, 463 (2010)

M.S. Hesarian, M. Eshkevari, M. Jahangoshai Rezaee, Int. J. Comput. Int. Manuf. 33, 1167 (2020)

F. Memarian, M. Amani, M. Latifi, Fiber. Polym. 12, 830 (2011)

J. Wang, K. Shi, L. Wang, Z. Li, F. Sun, R. Pan, W. Gao, IEEE Access 8, 26966 (2020)

X.F. Sun, Q. Wang, W. Gao, Text. Res. J 90, 333 (2020)

M.S. Hesarian, J. Tavoosi, Adv. Environ. Technol. 5, 35 (2019)

M.S. Hesarian, M. Eshkevari, M. Jahangoshai Rezaee, Int. J. Comput. Int. Manuf 33, 1167 (2020)

M.S. Hesarian, J. Tavoosi, S.H. Hosseini, Int. J. Eng 33, 2443 (2020)

Z. Zhou, Y. Hu, Z. Zhu, Y. Wang, J. Nat. Fibers (2023). https://doi.org/10.1080/15440478.2022.2163026

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We certify that there is no actual or potential conflict of interest in relation to this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hesarian, M.S., Tavoosi, J. Prediction the Effect of Tensile and Elongation Properties of Dry and Wet Cotton Fibre on the Fabric Wrinkle Grade Based on Polynomial Type2 Fuzzy Neural Network Modelling. Fibers Polym 24, 2255–2262 (2023). https://doi.org/10.1007/s12221-023-00229-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00229-1