Abstract

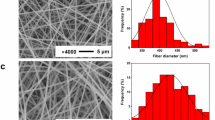

There are different methods for producing core–shell nanofibers, one of which is the emulsion electrospinning method. The stability of the emulsion during electrospinning is one of the most critical factors in the quality of the fibers. In this study, a magnetic-field-assisted emulsion electrospinning system was designed, built, and tested to keep the emulsion stable without additives or sonication. Polycaprolactone (PCL) 10 wt. % in dichloromethane (DCM) for the shell and gelatin 2.5 wt. % in water for the core was used. Scanning electron microscope (SEM) image of samples with different weight ratios of components both with and without using the magnetic-field-assisted emulsion electrospinning system at different rotational speeds was investigated. Transition electron microscope (TEM) images of the sample with a ratio of 1/10 (gel/PCL) at different rotational speeds were studied. The fibers were finally analyzed by Fourier transform infrared (FTIR) and tensile strength machine. According to the results, there was no change in the bonds in the materials after electrospinning. The designed system improved the fiber texture and reduced its structural problems significantly. By increasing the rotation speed of the magnet from 700 to 900 rpm, an improvement in fiber morphology and uniformity in diameter was observed. The composition of gelatin/PCL with a ratio of 1/10 was selected as the optimal condition. The spun nanofibers in these conditions had a uniform structure without the bead, and the presence of both polymers uniformly in the fibers was shown. Finally, the magnetic-field-assisted emulsion electrospinning system successfully held the emulsion stable during electrospinning without additives.

Similar content being viewed by others

Availability of Data and Materials

The authors confirm that all data are available within the article.

References

N. Bhardwaj, S.C. Kundu, Biotechnol. Adv. 28, 325 (2010)

N. Jirofti, D. Mohebbi-Kalhori, A. Samimi, A. Hadjizadeh, G.H. Kazemzadeh, Biomed. Mater. 13, 55014 (2018)

H. Savoji, A. Hadjizadeh, M. Maire, A. Ajji, M.R. Wertheimer, S. Lerouge, Macromol. Biosci. 14, 1084 (2014)

J. Yang, Sci. Prepr. (2022). https://doi.org/10.14293/S2199-1006.1.SOR-.PPOFGWR.v1

M.F. Elahi, W. Lu, G. Guoping, F. Khan, J. Bioeng. Biomed. Sci 3, 1 (2013)

W. Xia, G. Peng, Y. Hu, G. Dou, Polym. Eng. Sci. 62, 247 (2022)

A. Hasan, A. Memic, N. Annabi, M. Hossain, A. Paul, M.R. Dokmeci, F. Dehghani, A. Khademhosseini, Acta Biomater. 10, 11 (2014)

T. Jiang, E.J. Carbone, K.W.-H. Lo, C.T. Laurencin, Prog. Polym. Sci. 46, 1 (2015)

W. Chen, D. Li, E.-S. Ahmed, M. El-Newehy, H.A. Ei-Hamshary, S.S. Al-Deyab, C. He, X. Mo, Colloids Surf. B Biointerfaces 126, 561 (2015)

S. Agarwal, J.H. Wendorff, A. Greiner, Polymer (Guildf) 49, 5603 (2008)

R. Ramalingam, C. Dhand, C.M. Leung, H. Ezhilarasu, P. Prasannan, S.T. Ong, S. Subramanian, M. Kamruddin, R. Lakshminarayanan, S. Ramakrishna et al., Nanomaterials 9, 462 (2019)

M. Badmus, J. Liu, N. Wang, N. Radacsi, Y. Zhao, Nano Mater. Sci. 3, 213 (2021)

J. Avossa, G. Herwig, C. Toncelli, F. Itel, R. M. Rossi, Green Chem. 24, 2347 (2022)

N. Nikmaram, S. Roohinejad, S. Hashemi, M. Koubaa, F.J. Barba, A. Abbaspourrad, R. Greiner, RSC Adv. 7, 28951 (2017)

K. Zhou, M. Wang, Y. Zhou, M. Sun, Y. Xie, D.-G. Yu, Adv. Compos. Hybrid Mater. 5, 907 (2022)

A. Barhoum, K. Pal, H. Rahier, H. Uludag, I.S. Kim, M. Bechelany, Appl. Mater. Today 17, 1 (2019)

X. Qin, Coaxial electrospinning of nanofibers, in Electrospun nanofibers, Elsevier (2017), pp. 41–71.

F. Li, Y. Zhao, Y. Song, Nanofibers 2, 418 (2010)

X. Xu, X. Chen, X. Wang, X. Jing et al., Eur. J. Pharm. Biopharm. 70, 165 (2008)

X. Xu, L. Yang, X. Xu, X. Wang, X. Chen, Q. Liang, J. Zeng, X. Jing, J. Control. Release 108, 33 (2005)

P.J. Garc’ia-Moreno, K. Stephansen, J. van der Kruijs, A. Guadix, E.M. Guadix, I.S. Chronakis, C. Jacobsen, J. Food Eng. 183, 39 (2016)

M.F. Abdullah, T. Nuge, A. Andriyana, B.C. Ang, F. Muhamad, Polymers (Basel) 11, 2008 (2019)

F. Kashani-Asadi-Jafari, A. Hadjizadeh, Pharm. Nanotechnol. 56, 10 (2022)

F. Kashani-Asadi-Jafari, A. Aftab, S. Ghaemmaghami, Int. J. Pharm. 627, 122203 (2022)

J. Hu, M.P. Prabhakaran, X. Ding, S. Ramakrishna, J. Biomater. Sci. Polym. Ed. 26, 57 (2015)

A. Hadjizadeh, A. Ajji, M.N. Bureau, J. Mech. Behav. Biomed. Mater. 4, 340 (2011)

R.K. Mishra, A.B.A. Majeed, A.K. Banthia, Int. J. Plast. Technol. 15, 82 (2011)

Y. Wu, X. Qiu, S. Cao, J. Chen, X. Shi, Y. Du, H. Deng, J. Colloid Interface Sci. 539, 533 (2019)

A.L. Yarin, Polym. Adv. Technol. 22, 310 (2011)

G.H. Kim, H. Nam, W. Choi, T. An, G. Lim, Adv. Mater. Interfaces 5, 1701204 (2018)

C.J. Angammana, S.H. Jayaram, IEEE Trans. Ind. Appl. 47, 1028 (2011)

J.-H. He, Y.-Q. Wan, Int. J. Nonlinear Sci. Numer. Simul. 5, 243 (2004)

Y. Dai, J. Niu, J. Liu, L. Yin, J. Xu, Bioresour. Technol. 101, 8942 (2010)

K. Wang, X. Chen, Y. Pan, Y. Cui, X. Zhou, D. Kong, Q. Zhao, Biomed Res. Int. 2015, 865076 (2015)

Acknowledgements

We thank Mr. Arya Aftab for his kind help in writing the article in terms of language editing. We also thank the Amirkabir University of Technology for providing laboratory equipment and funding for this study.

Funding

This study was funded by Amirkabir University of Technology (Grant No. GN2020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kashani-Asadi-Jafari, F., Parhizgar, A. & Hadjizadeh, A. Magnetic-Field-Assisted Emulsion Electrospinning System: Designing, Assembly, and Testing for the Production of PCL/Gelatin Core–Shell Nanofibers. Fibers Polym 24, 515–523 (2023). https://doi.org/10.1007/s12221-023-00111-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00111-0