Abstract

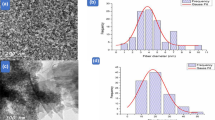

Inspired by functioned textile materials, in this research a one-step technique is implemented for the preparation of super antibacterial and ultra-voilet (UV) blocking surface properties of lyocell fabrics by a specific amount of zinc oxide nanoparticles (ZnONPs) and various fractions of cellulose nanofibrils (CNF). The combination of cellulose nanofibrils and zinc oxide nanoparticles caused a transformation of pristine lyocell fabric into functional fabric by enhancing its mechanical, antibacterial, and ultra-voilet blocking properties. In the first portion of this research cellulose nanofirbils were extracted from a cellulose rich biomass Ficus natalensis barkcloth through chemical treatments and catalytic oxidation of cellulose using 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) combined with mechanical homogenization. Secondly coating of cellulose nanofibrils and zinc oxide nanoparticles was done on lyocell fabrics. Based on the morphological analysis, equal distribution of CNF andf ZnONPs on the lyocell fabrics’ surfaces was tremendously improved leading to a much more uniform rough structure. However, with the increase of cellulose nanofibrils content, coating was unsmooth and crackes on the fabric surface were cleared due to accumulation of CNF at higher concentration. Results demonstrated an obvious increase of mechanical properties of lyocell fabrics with the addition of cellulose nanofibrils till 0.5 wt%. Similarly washing fastness studies showed that the fabric UV blocking properties were stable, whereas antibacterial characteristics of lyocell fabrics were significantly increased after CNF and zinc oxide nanoparticles coating.

Similar content being viewed by others

References

H. Ma, C. Burger, B. S. Hsiao, and B. Chu, Biomacromolecules, 12, 970 (2011).

N. Mengal, U. Syed, S. A. Malik, I. A. Sahitoa, and S. H. Jeong, Carbohydr. Polym., 153, 78 (2016).

R. Ibbett, H. Owens, R. Reisel, and A. H. M. Renfrew, Color, 2, 123 (2009).

B. Siroka, M. Noisternig, U. J. Griesser, and T. Bechtold, Carbohydr. Res., 343, 2194 (2008).

T. H. Mokhothu and M. J. John, Carbohydr. Polym., 131, 337 (2015).

L. Cai, Y. Peng, J. Xu, C. Zhou, C. Zhou, P. Wu, D. Lin, S. Fan, and Y. Cui, Joule, 3, 1478 (2019).

M. I. Tendo, W. Hua, and J. Sun, Eur. J. Wood Wood Prod., 77, 483 (2019).

S. Rwawiire, B. Tomkova, J. Militky, L. Hes, and B. M. Kale, Appl. Acoust., 116, 177 (2017).

P. Chen, H. Wang, M. He, B. Chen, B. Yang, and B. Hu, Ecotoxicol. Environ. Saf., 171, 337 (2019).

R. B. d’Água, R. Branquinho, M. P. Duarte, E. Maurício, A. L. Fernando, R. Martins, and E. Fortunato, New J. Chem., 42, 1052 (2018).

B. Butola, A. Garg, A. Garg, and I. Chauhan, J. Inst. Eng. India Ser. E, 99, 93 (2018).

Y. Y. Chu, Z. Guo, Q. Wang, and S. Z. Cui, Adv. Mat. Res., 441, 266 (2012).

M. E. El-Naggar, T. I. Shaheen, S. Zaghloul, M. H. El-Rafie, and A. Hebeish, Indus. Eng. Chem. Res., 55, 2661 (2016).

E. Pakdel, W. A. Daoud, T. Afrin, L. Sun, and X. Wang, Cellulose, 24, 4003 (2017).

N. A. Ibrahim, A. A. Aly, B. M. Eid, and H. M. Fahmy, Fiber. Polym., 19, 2298 (2018).

E. S. Ates and H. E. Unalan, Thin Solid Films, 14, 4658 (2012).

S. Azizi, M. Ahmad, N. Ibrahim, M. Hussein, and F. Namvar, Int. J. Mol. Sci., 15, 11040 (2014).

H. Liu, J. Song, S. Shang, Z. Song, and D. Wang, ACS Appl. Mater. Interfaces, 4, 2413 (2012).

H. M. Ng, L. T. Sin, T. T. Tee, S. T. Bee, D. Hui, C. Y. Low, and A. R. Rahmat, Compos., 15, 176 (2015).

A. Farooq, S. Jiang, A. Farooq, M. A. Naeem, A. Ahmad, and L. Liu, J. Ind. Text., 51, 664 (2019).

M. Li, A. Farooq, S. Jiang, M. Zhang, H. Mussana, and L. Liu, Text. Res. J., 91, 2303 (2021).

T. Saito and A. Isogai, Biomacromolecules, 5, 1983 (2004).

G. L. Devnani and S. Sinha, Compos. Pt. B-Eng., 166, 436 (2019).

D. Haldar and M. K. Purkait, Carbohydr. Polym., 250, 116937 (2020).

H. Jakob, P. Fratzl, and S. Tschegg, J. Struct. Biol., 113, 13 (1994).

A. De Nooy, A. C. Besemer, H. Van Bekkum, J. Van Dijk, and J. Smit, Macromolecules, 29, 6541 (1996).

Y.-R. Zhang, J.-T. Chen, B. Hao, R. Wang, and P.-C. Ma, Carbohydr. Polym., 240, 116318 (2020).

T. Yi, H. Zhao, Q. Mo, D. Pan, Y. Liu, L. Huang, H. Xu, B. Hu, and H. Song, Materials, 22, 5062 (2020).

X. Yang, Y. Zhao, H. Mussana, M. Tessema, and L. Liu, Mater. Lett., 211, 300 (2018).

R. Faisal, N. Sanbhal, T. Naveed, A. Farooq, Y. Wang, and W. Wei, Cellulose, 25, 4251 (2018).

A. Becheri, M. Dürr, P. L. Nostro, and P. Baglioni, J. Nanopart. Res., 10, 679 (2008).

A. A. Tayel, W. F. E-Tras, S. Moussa, A. F. E-Baz, H. Mahrous, M. F. Salem, and L. Brimer, J. Food Saf., 31, 211 (2011).

K. Lefatshe, C. M. Muiva, and L. P. Kebaabetswe, Carbohydr. Polym., 164, 301 (2017).

S. Anitha, B. Brabu, D. J. Thiruvadigal, C. Gopalakrishnan, and T. Natarajan, Carbohydr. Polym., 87, 1065 (2012).

C. A. Ghiorghita, F. Bucatariu, and E. S. Dragan, Mater. Sci. Eng. C, 105, 110050 (2019).

Acknowledgements

For this research paper, publication, and authorship, the authors reveal the receipt of the following financial support. The work was completely supported by “National Key R&D Program of China (2018YFC2000900)” and “Fundamental Research Funds for the Central Universities” (2232018A3-04)”.

Author information

Authors and Affiliations

Corresponding author

Supplementary data

Rights and permissions

About this article

Cite this article

Farooq, A., Patoary, M.K., Zhao, Y. et al. An Eco-friendly Route to Prepare Cellulose Based Multifunctional Lyocell Fabrics Using Zinc Oxide and Cellulose Nanofibrils Network. Fibers Polym 23, 1275–1283 (2022). https://doi.org/10.1007/s12221-022-4733-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4733-8