Abstract

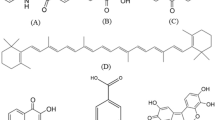

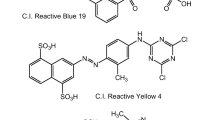

This study was conducted to develop an effective mordanting method for black color expression of silk and cotton fabrics using the neutral extract (NE) of Pinus radiata bark and various iron mordants. Also, mordanting characteristics of iron salts in equimolar concentrations were evaluated. The mordanting was carried out in methods of pre-, post-, and pre- and then post-mordanting in one process with ferrous sulfate (FeSO4), ferrous chloride (FeCl2), ferrous acetate (Fe(CO2CH3)2), ferrous lactate (Fe-lac, Fe(CH3CH(OH)CO2)2, ferric sulfate (Fe2(SO4)3), and ferric chloride (FeCl3). The mordant concentration was 1 mM o.w.f. (on the weight of fabric); 0.5 mM for Fe2(SO4)3. The colors of mordanted silk fabrics ranged from dark brown to black and that of mordanted cotton fabric were in the range of light grayish-brown to gray. Using ferrous ion (Fe2+) and post-mordanting methods led to the expression of darker colors and the divalent and trivalent cations (Fe ions) were found to influence dark color expression. The color of silk fabric in the presence of the combination of Fe2(SO4)3 pre- and Fe-lac post-mordanting (PSPL) was closest to the silk fabric dyed with synthetic black dye. Based on the colorfastness assessment, an increase in the light fastness of PSPL silk fabric was observed along with a decrease in the rubbing fastness compared to the non-mordanted silk.

Similar content being viewed by others

References

Y. M. Yeo and Y. S. Shin, Text. Color. Finish., 29, 276 (2017).

S. H. Seok and K. S. Geum, J. Korean Soc. Costume, 62, 29 (2012).

H. L. Yoon, “Color Perception and Systemology”, p.26, Kukjebook, Seoul, 2008.

M. V. Cañamares, D. A. Reagan, J. R. Lombardi, and M. Leona, J. Raman Spectrosc., 45, 1147 (2014).

S. Singh and D. R. Singh, Int. J. Appl. Home Sci., 5, 252 (2018).

A. Hooda and A. Rangi, J. Basic App. Eng. Res., 2, 43 (2015).

A. K. Samanta and A. Konar in “Natural Dyes” (E. A. Kimbasar Ed.), pp.29–31, IntechOpen, Rijeka, 2011.

M. Mirjalili, K. Nazarpoor, and L. Karimi, J. Cleaner Prod., 19, 1045 (2011).

R. Kant, Nat. Sci., 4, 22 (2015).

R. N. Bharagava in “Textile Industry Wastewater: Environmental and Health Hazards and Treatment Approaches” (S. Mani and R. N. Bharagava Eds.), pp.48–64, CRC Press, Boca Raton, 2018.

K. R. Cho, “Studies in Natural Dyeing”, p.245, Hyungseul, Seoul, 2010.

J. N. Lee and E. J. Lee, J. Fash. Bus., 21, 166 (2017).

J. N. Lee, “What We Really Should Know Natural Dyeing”, pp.180–181, Hyeonamsa, Seoul, 2004.

A. Haji, M. K. Mehrizi, and J. Sharifzadeh, Fiber. Polym., 17, 1480 (2016).

S. Adeel, K. M. Zia, M. Abdullah, Fu. Rehman, M. Salman, and M. Zuber, Nat. Prod. Res., 33, 2060 (2019).

S. Adeel, Fu. Rehman, M. K. Khosaa, S. Rajaba, K. M. Ziaa, M. Zuber, and F. Batoold, J. Nat. Fibers, doi: https://doi.org/10.1080/15440478.2020.1870618 (2021).

M. J. Kwak, Master’s Thesis, DCU, Daegu, 2002.

N. Amin, Fu. Rehman, S. Adeel, T. Ahamd, M. Muneer, and A. Haji, Environ. Sci. Pollut. Res., 27, 6851 (2020).

S. Adeel, S. Kiran, T. Ahmad, H. Noman, K. Tariq, and M. Hussaan in “Frontiers of Textile Materials: Polymers, Nanomaterials, Enzymes, and Advanced Modification Techniques”, 1st ed. (M. Shabbir, S. Ahmed, and J. N. Sheikh Eds.), p.344, Wiley-Scrivener Publishing, Online, 2020.

J. Y. Kang, J. E. Lee, S. Y. Kim, G. T. Park, and J. S. Park, J. Environ. Sci. Int., 27, 457 (2018).

R. Karban and I. T. Baldwin, “Induced Responses to Herbivory”, p.108, University of Chicago Press, Illinois, 2007.

Korea Forest Service (KFS), “Statistical Yearbook of Forestry”, Report No. 49, 2020.

C. S. Ku, J. P. Jang, and S. P. Mun, J. Wood Sci., 53, 524 (2007).

J. S. Mun, H. C. Kim, and S. P. Mun, J. Korean Wood Sci. Technol., 48, 878 (2020).

C. S. Ku, S. P. Mun, and J. P. Jang, Forest Prod. J., 61, 321 (2011).

Enzogenol, https://www.enzogenol.com (Accessed August 3, 2020).

Pycnogenol, https://www.pycnogenol.com/home (Accessed August 3, 2020).

Y. H. Choi, C. H. Song, and S. P. Mun, Phytother. Res., 32, 290 (2018).

J. S. Mun, H. C. Kim, and S. P. Mun, J. Korean Wood Sci. Technol., 49, 134 (2021).

KS K ISO 105-C06:2018, “Textiles-Tests for Colour Fastness-Part C06: Colour Fastness to Domestic and Commercial Laundering”, 2018.

KS K ISO 105-X12:2017, “Textiles-Tests for Colour Fastness-Part X12: Colour Fastness to Rubbing”, 2017.

KS K ISO 105-B02:2015, “Textiles-Tests for Colour Fastness-Part B02: Colour Fastness to Artificial Light: Xenon arc Fading Lamp Test”, 2015.

E-paint.co.uk, https://www.e-paint.co.uk/Convert_lab.asp, (Accessed August 10, 2020).

V. Chobot and F. Hadacek, Plant Signal. Behav., 5, 4 (2010).

E. Wiberg, A. F. Holleman, and N. Wiberg, “Inorganic Chemistry”, 1st ed., p.1440, Academic Press, San Diego, London, 2001.

K. S. Prezewozna, Proc. Text. Inst. 82nd World Conf., Egypt, CD-ROM, 2002.

M. G. Uddin, J. Text., 2014, 405626 (2014).

M. Shabbir, S. U. Islam, M. N. Bukhari, L. J. Rather, M. A. Khan, and F. Mohammad, Text. Cloth. Sustain., 2, 1 (2016).

C. S. Ku, M. Sathishkumar, and S. P. Mun, Chemosphere, 67, 1618 (2007).

S. D. Bhattacharya and A. K. Shah, Color. Technol., 116, 10 (2000).

Acknowledgment

The authors would like to acknowledge technical assistance provided from the CURF (JBNU).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mun, J.S., Kim, H.C. & Mun, S.P. Black Color Expression of Silk and Cotton Fabrics Using Neutral Extract from Pinus radiata Bark and Various Iron Mordants. Fibers Polym 23, 1008–1017 (2022). https://doi.org/10.1007/s12221-022-4227-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4227-8