Abstract

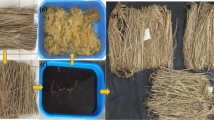

The textile uses of the aquatic plant ‘Typha latifolia L.’ (genus Typha) have not been previously explored. The current research is the first of its kind to examine the optimization of fibre extraction and fibre properties of this wetland biomass and compare them with the two most widely used fibres: cotton and wool. It was found that Typha leaves and the core spongy stem tissue could be transformed into fibres under controlled experimental conditions in an aqueous alkaline solution, yielding 30 % to 50 %. The average diameter of individual Typha fibres, the moisture regain (%), and thermal resistance were found to be comparable to cotton and wool. Scanning Electron Microscopy (SEM) images revealed a unique submicroscopic ‘crenelated’ structure of Typha fibres, which consisted of radially-shaped cells (4.5–6.0 µm) with a lumen (≈1.03 µm) and ‘canal’ between the cells. The dye exhaustion of Typha was similar to cotton while the colour fastness was within the industry requirements. However, the stiffness of the Typha fibre was higher than that of cotton and polyester, which would make Typha fibres more difficult to process in conventional cotton spinning systems.

Similar content being viewed by others

References

Y. Wang in “Recycling in Textiles”, 1st ed. (Y. Wang Ed.), pp.1–3, Woodhead Publishing, Cambridge, England, 2006.

Y. Jiang and K. Loos, Polymers, 8, 243 (2016).

M. R. I. Khan, Masters Dissertation, University of Manitoba, Winnipeg, Canada, 2016.

M. Dochia, C. Sirghie, A. Vlaicu, R. M. Kozlowski, Z. Roskwitalski, and I. B. Gdynia in “Handbook of Natural Fibres”, 1st ed. (R. M. Kozlowski Ed.), Vol. 1, pp.11–22, Woodhead Publishing Company Inc. Cambridge, England, 2012.

B. Rashid, I. Yousaf, T. Haider, Z. Rasheed, Q. Ali, F. Javed, and T. Husnain, Life Sci. J., 13, 41 (2016).

W. W. F. Global, The Impact of a Cotton T-Short: How Smart Choices Can Make a Difference in Our Water and Energy Footprint, https://www.worldwildlife.org/stories/the-impact-of-a-cotton-t-shirt#, 2013.

G. Judkins, Yearbook of the Association of Pacific Coast Geographers, 70, 70 (2008).

A. H. Arthington, GeoJournal, 40, 115 (1996).

S. Roy and L. B. Lutfar in “Handbook of Natural Fibres”, 1st ed. (R. M. Kozlowski Ed.), Vol. 1, pp.24–55, Woodhead Publishing Company Inc. Cambridge, England, 2012.

R. M. Kozlowski and M. Mackiewicz-Talarczyk “Handbook of Natural Fibres”, 1st ed. (R. M. Kozlowski Ed.), Vol. 1, pp.1–8, Woodhead Publishing Company Inc. Cambridge, England, 2012.

R. R. Mather and R. H. Wardman, “The Chemistry of Textile Fibres”, 2nd ed. pp.22–60, The Royal Society of Chemistry, Cambridge, UK, 2015.

S. J. Minotte and R. R. Franck, “Flax”, In Bast and other Plant Fibres, (R. R. Franck Ed.), pp.94–175, Woodhead Publishing, Cambridge, England, 2005.

A. Ali, M.Sc. Dissertation, University of Manitoba, Winnipeg, Canada, 2013.

G. P. Sevenhuysen and M. Rahman, U.S. Patent, WO2015039243 (2016).

Canola Council of Canada. Industry Overview. In Markets and Stats. https://www.Brassicacouncil.org/markets-stats/industry-overview, 2018.

I. I. Shuvo, M. Rahman, T. Vahora, J. Morrison, S. DuCharme, and L.-P. Choo-Smith, Text. Res. J., https://doi.org/10.1177/0040517519886636 (2019).

V. Sadrmanesh, Y. Chen, M. Rahman, and F. AL-Oqla, J. Clean. Prod., https://doi.org/10.1016/j.jclepro.2019.117891 (2019).

J. E. Houlahan, P. A. Keddy, K. Makkay, and C. S. Findlay, Wetlands, 26, 79 (2006).

R. Sana, J. Mounir, and M. Slah, Int. J. Res. Eng. Technol., 3, 539 (2014).

T. Luamkanchanaphan, S. Chotikaprakhan, and S. Jarusombati, APCBEE Procedia, doi: https://doi.org/10.1016/j.apcbee.2012.03.009 (2012).

O. Maizatul, G. Ruzaidi, K. Khalisanni, and Z. Nazarudin, Adv. Mat. Res., 576, 492 (2012).

S M. Mortazavi and M. K. Moghadam, J. Appl. Polym. Sci., 113, 3307 (2009).

J. B. Grace and R. G. Wetzel, Can. J. Bot., 60, 46 (1982).

Standard Test Method for Moisture in Cotton by Oven-drying, ASTM Standard; D2495-07, Annual Book of ASTM Standard, Vol. 7.01., https://doi.org/10.1520/D2495-07R12 (2012).

Standard Test Method for Yarn Crimp and Yarn Take-up in Woven Fabrics, ASTM Standard; D3883-2016, Annual Book of ASTM Standard, Vol. 7.02., https://compass-astm-org.uml.idm.oclc.org/download/D3883.40564.pdf (2016).

https://www.colorcodepicker.com, Image Colour Picker.

https://www.colorhexa.com, ColorHexa, Color encyclopedia, Information & Conversion.

E. R. Trotman, “Dyeing and Chemical Technology of Textile Fibres”, 5th ed., pp.540–564, Charles Griffin and Company Ltd. London and High Wycombe, 1970.

AATCC Technical Manual. American Association of Textile Chemists & Colorists Method 133: Colorfastness to Heat: Hot Pressing, Howes Pub. Co. New York, USA, 2009.

A. Broadbent, “Basic Principles of Textile Coloration”, 1st ed., pp.338–339, Society of Dyers and Colourists, Thanet Press Ltd, Kent, England, 2001.

Standard Test Method for Fabric Hand: Guidelines for the Subjective Evaluation, Method EP 5, AATCC Technical Manual, American Association of Textile Chemists & Colorists, Howes Pub. Co. New York, USA, 2012.

K. Hatch, Textile Identification Manual with Textile Collection, University of Arizona, Tucson, Arizona, USA, 2006.

D. Fahlgren, D. M.Sc. Dissertation, Swedish University of Agricultural Sciences, Almas Allé 8, 750 07 Uppsala, Sweden, 2017.

J. L. Sharp, M.Sc. Dissertation. University of North Texas, Texas, USA. 2002.

M. Krus, W. Theuerkorn, T. Großkinsky and H. Künzel, (2014). New Sustainable and Insulating Building Material Made of Cattail. Nordic Symposium on Building Physics (NSB), pp.1252–1260, http://publica.fraunhofer.de/documents/N323927.html (2014).

Uster Statistics, The Quality Benchmark for the Textile Industry, Uster, Switzerland Uster Technologies AG Publishing, 2007.

M. K. Moghaddam and S. M. Mortazavi, J. Nat. Fibres, 13, 353 (2016).

J. B. Grace and R. G. Wetzel, Ecology, 62, 789 (1981).

J. A. Dickerman and R. G. Wetzel, J. Ecol., 73, 535 (1985).

J. B. Grace and J. S. Harrison, Can. J. Plant Sci., 66, 361 (1986).

R. S. Krowicki, J. M. Hemstreet, and K. E. Duckett, J. Text. Inst., 88, 167 (1997).

M. Lewin, M. Shiloh, and J. Banbaji, Text. Res. J., 29, 373 (1959).

A. Witztum and R. Wayne, Ann. Bot., 113, 789 (2014).

K. L. Hatch, “Textile science”, The University of Arizona Revised Edition, pp.142–153, pp.163–171, Saint Paul, Minneapolis, 2006.

Y. Cai, M. T. Pailthorpe, and S. K. David, Text. Res. J., 69, 440 (1999).

M. Hamdaoui, S. Turki, Z. Romdhani, and S. Halaoua, Indian J. Fibre Text., 38, 405 (2013).

S. Acharya, N. Abidi, R. Rajbhandari, and F. Meulewaeter, Cellulose, 21, 4693 (2014).

Standard Performance Specifications for Men’s and Boy’s Knitted Dress Suit Fabrics and Knitted Sportswear Jacket, Slack, and Trouser Fabrics, ASTM Standard D3782, Annual Book of Standards, Vol. 7.02, 2008.

P. G. Cookson and I. J. Slota, Text. Res. J., 63, 495 (1993).

Y. Xia, C. Hill, Z. Jalaudin, C. Simon, A. Rajesh, N. Andrew, and N. Gary, J. Mat. Sci., 46, 479 (2011).

V. Sopit, J. Biological Sci., 7, 218 (2007).

M. Hasan, Masters Dissertation, University of Manitoba, Winnipeg, Canada, 2019.

W. E. Morton and J. W. S. Hearle, “Physical Properties of Textile Fibres”, 4th ed., pp.321–274, Chap.13, Woodhouse Publishing Ltd. Cambridge, England, 2008.

M. Zimniewska and A. Kicińska-Jakubowska, Animal Fibres Sheet, Institute of Natural Fibres & Medicinal Plants, https://dnfi.org/wp-content/uploads/2012/01/fact-sheet-animal-fibers.pdf.

A. Arshad, Masters Dissertation, University of Manitoba, Winnipeg, Canada, 2013.

S. H. Zeronian, Q. Xie, G. Buschle-DiUer, S. Holmes, and M. K. Inglesby, J. Text. Inst., 85, 293 (1994).

Acknowledgement

The authors are thankful to Dr. Ravinder Sidhu of the Manitoba Institute for Materials (MIM) for help in SEM works. The first author is acknowledged for the funding from the Natural Sciences and Engineering Research Council of Canada (NSERC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahman, M., Cicek, N. & Chakma, K. The Optimum Parameters for Fibre Yield (%) and Characterization of Typha latifolia L. Fibres for Textile Applications. Fibers Polym 22, 1543–1555 (2021). https://doi.org/10.1007/s12221-021-0194-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0194-8