Abstract

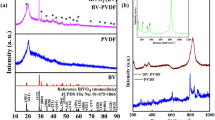

In this study, electrospun polyvinylidene fluoride (PVDF)-based nanofibrous membranes embedding TiO2 were prepared and used for photocatalytic degradation and oil/water separation. The nanofibrous membranes were characterized by scanning electron microscopy (SEM), transmission electronic microscope (TEM), X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR) spectroscopy, thermal performance analysis, and oil/water separation analysis. And the degradation of rhodamine B dye was also investigated. Results showed that the fiber diameter and thermal stability of the membranes decreased with the increasing of TiO2. Meanwhile, the fiber surface roughness and specific surface area increased. The analysis of TEM, XRD and FTIR indicated that TiO2 existed in the PVDF membranes. When the TiO2 content was 12 %, the fiber diameter of the membranes was about 110 nm, and the photocatalytic degradation of rhodamine B dye efficiency was up to 97 %. The reaction rate constant was 0.02057 min−1. At 0.01 MPa vacuum, oil separated from water effectively, which proves that separation can be easily conducted with a low energy cost. Thus, the prepared membranes have a very high application prospect in the purification of reclaimed water and separation of oil and water.

Similar content being viewed by others

References

P. C. Chen and Z. K. Xu, Sci. Rep-UK, 3, 2776 (2013).

H. Huang, Z. Song, N. Wei, L. Shi, Y. Mao, Y. Ying, L. Sun, Z. Xu, and X. Peng, Nat. Commun., 4, 2979 (2013).

X. Lin, Q. Yang, L. Ding, and B. Su, ACS Nano, 9, 11266 (2015).

P. Dong, Y. Wang, L. Guo, B. Liu, S. Xin, J. Zhang, Y. Shi, W. Zeng, and S. Yin, Nanoscale, 4, 4641 (2012).

Y. Liang, H. Wang, H. S. Casalongue, Z. Chen, and H. Dai, Nano Res., 3, 701 (2010).

T. Liu, S. Sun, L. Zhou, P. Li, Z. Su, and G. Wei, Appl. Sci., 9, 293 (2019).

B. M. Kale, J. Wiener, J. Militky, S. Rwawiire, R. Mishra, K. I. Jacob, and Y. Wang, Carbohydr. Polym., 150, 107 (2016).

M. M. Ghobashy, Ultrason. Sonochem, 37, 529 (2017).

G. Doganli, B. Yuzer, I. Aydin, T. Gultekin, A. H. Con, H. Selcuk, and S. Palamutcu, J. Coat. Technol. Res., 13, 257 (2016).

S. Sun, T. Deng, H. Ding, Y. Chen, and W. Chen, Nanomaterials, 7, 367 (2017).

A. Folli, U. H. Jakobsen, G. L. Guerrini, and D. E. Macphee, J. Adv. Oxid. Technol., 12, 126 (2016).

T. Shirasawa, W. Voegeli, E. Arakawa, T. Takahashi, and T. Matsushita, J. Phys. Chem. C, 120 (2016).

A. Y. Shan, T. I. M. Ghazi, and S. A. Rashid, Appl. Catal. A-Gen, 389, 1 (2010).

G. Zhang, J. Yi, J. Shim, J. Lee, and W. Choi, Appl. Catal. B-Environ., 102, 132 (2011).

S. Carbonaro, M. N. Sugihara, and T. J. Strathmann, Appl. Catal B-Environ., 129, 1 (2013).

S. Singh, H. Mahalingam, and P. K. Singh, Appl. Catal. A-Gen, 462–463, 178 (2013).

T. He, Z. Zhou, W. Xu, F. Ren, H. Ma, and J. Wang, Polymer, 50, 3031 (2009).

S. Jo and Y. Kim, Korean J. Chem. Eng., 33, 3203 (2016).

J. Li, L. Yan, W. Hu, D. Li, F. Zha, and Z. Lei, Colloid Surface A, 489, 441 (2016).

L. Li, Z. Liu, Q. Zhang, C. Meng, T. Zhang, and J. Zhai, J. Mater. Chem. A., 3, 1279 (2015).

S. Singh, H. Mahalingam, and P. K. Singh, Appl. Catal A-Gen, 462–463, 178 (2013).

N. S. Mohamed and A. K. Arof, J. Power. Sources, 132, 229 (2004).

C. Chiang, Y. J. Shen, M. J. Reddy, and P. P. Chu, J. Power. Sources, 123, 222 (2003).

X. Yue, Z. Li, T. Zhang, D. Yang, and F. Qiu, Chem. Eng. J., 364, 292 (2019).

T. Liu, Y. Guo, Z. Zhang, Z. Miao, X. Zhang, and Z. Su, Sensor. Actuat. B-Chem, 286, 370 (2019).

M. Zhang, X. Zhao, G. Zhang, G. Wei, and Z. Su, J. Mater. Chem. B, 5, 1699 (2017).

N. Hoogesteijn Von Reitzenstein, X. Bi, Y. Yang, K. Hristovski, and P. Westerhoff, J. Appl. Polym. Sci., 133 (2016).

S. Zhang, Z. Jia, T. Liu, G. Wei, and Z. Su, Sensors, 19, 3977 (2019).

R. M. Ahmed, Fiber and Integrated Optics, 36, 78 (2017).

T. He, Z. Zhou, W. Xu, F. Ren, H. Ma, and J. Wang, Polymer, 50, 3031 (2009).

S. Ramasundaram, A. Son, M. G. Seid, S. Shim, S. H. Lee, Y. C. Chung, C. Lee, J. Lee, and S. W. Hong, J. Hazard. Mater, 285, 267 (2015).

A. Salimi and A. A. Yousefi, Polym. Test., 22, 699 (2003).

Q. Jiang, X. Pei, L. Wu, T. Li, and J. Lin, Adv. Polym. Tech., 37, 2971 (2018).

S. W. Choi, S. M. Jo, W. S. Lee, and Y. R. Kim, Adv. Mater., 15, 2027 (2003).

A. Yar, B. Haspulat, T. Üstün, V. Eskizeybek, A. Avc, H. Kam, and S. Achour, RSC Adv., 7, 2986 (2017).

P. Dong, Y. Wang, L. Guo, B. Liu, S. Xin, J. Zhang, Y. Shi, W. Zeng, and S. Yin, Nanoscale, 4, 4641 (2012).

Z. Mokhtari-Shourijeh, L. Montazerghaem, and M. E. Olya, J. Polym. Environ., 26, 3550 (2018).

Y. Kim, C. H. Ahn, M. B. Lee, and M. Choi, Mater. Chem. Phys, 127, 137 (2011).

H. Bai, X. Wang, Y. Zhou, and L. Zhang, Pro. Nat. Sci-Mater, 22, 250 (2012).

A. Rahimpour, S. S. Madaeni, S. Zereshki, and Y. Mansourpanah, Appl. Surf. Sci., 255, 7455 (2009).

S. Gu, G. He, X. Wu, Z. Hu, L. Wang, G. Xiao, and L. Peng, J. Appl. Polym. Sci., 116, 852 (2009).

Z. Mokhtari-Shourijeh, L. Montazerghaem, and M. E. Olya, J. Polym. Environ., 26, 3550 (2018).

Y. Kim, C. H. Ahn, M. B. Lee, and M. Choi, Mater. Chem. Phys., 127, 137 (2011).

S. M. Seyed Shahabadi and J. A. Brant, Sep. Purif. Technol., 210, 587 (2019).

R. M. Ahmed, Fiber Integrated Opt., 36, 78 (2017).

Y. Liang, H. Wang, H. Sanchez Casalongue, Z. Chen, and H. Dai, Nano Res., 3, 701 (2010).

C. Lee, H. Javed, D. Zhang, J. Kim, P. Westerhoff, Q. Li, and P. J. J. Alvarez, Environ. Sci. Technol., 52, 4285 (2018).

B. Krishnakumar, S. Kumar, J. M. Gil, V. Pandiyan, A. Aguiar, and A. J. F. N. Sobral, J. Mol. Struct., 1153, 346 (2018).

L. Li, Z. Liu, Q. Zhang, C. Meng, T. Zhang, and J. Zhai, J. Mater. Chem. A., 3, 1279 (2015).

X. Yu, D. Lin, P. Li, and Z. Su, Sol. Energ. Mat. Sol. C., 172, 252 (2017).

Acknowledgements

This work was supported by the Open Project Program of Fujian Key Laboratory of Novel Functional Fibers and Materials (Minjiang University), China (No. FKLTFM 1722), National Natural Science Foundation of China [grant numbers 51503145, 21806121, 11702187]; the Natural Science Foundation of Tianjin City [grant numbers 18JCQNJC03400, 17JCQNJC08000]; the Natural Science Foundation of Fujian Province [grant numbers 2018J01504, 2018J01505]; the Opening Project of Green Dyeing and Finishing Engineering Research Center of Fujian University (2017001A, 2017001B, 2017002B and 2017004B), the Program for Innovative Research Team in University of Tianjin [grant number TD13-5043].

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sun, F., Ren, HT., Huang, SY. et al. Polyvinylidene Fluoride Electrospun Fibers Loaded TiO2 for Photocatalytic Degradation and Oil/Water Separation. Fibers Polym 21, 1475–1487 (2020). https://doi.org/10.1007/s12221-020-9949-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9949-x