Abstract

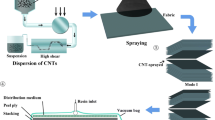

Due to growing interest in environmental protection, eco-friendly fibers with high specific strength and low cost are widely used to reinforce matrix materials. Flax fiber is a natural renewable plant fiber that originates from the phloem of flax. Flax fibers not only have the characteristics of other natural fibers but also have the outstanding mechanical properties of natural fibers. However, due to the large amount of hydrophilic hydroxyl groups on the surface, the hydrophilic absorption of flax fibers is large, and the wet-heat durability of the composite is poor, which limits the use of flax fiber as a reinforcement material in civil engineering applications. In this study, based on the research results of flax fiber, a flax fiber sheet was grafted with multiwalled carbon nanotubes, a silane coupling agent and nano-TiO2 particles. The effect of different treatment methods and process parameters on the mechanical and interfacial properties of flax fiber-reinforced plastic (FFRP) composites materials was studied. The results show that the FFRP composites grafted with multiwalled carbon nanotubes have higher tensile strength and interlaminar shear strength than those grafted with the same content of nano-TiO2 particles. Flax fiber composites with improved interfacial properties can be obtained by grafting flax fiber sheets, but the content of particles on the flax fiber surface should not exceed 2.0 wt.% of nano-TiO2 and multiwalled carbon nanotubes. Under this treatment, the FFRP composites have improved properties, such as tensile strength, interlaminar shear strength and glass transition temperature.

Similar content being viewed by others

References

X. Li, L. G. Tabil, and S. Panigrahi, J. Polym. Environ., 15, 25 (2007).

F. Z. Arrakhiz, M. El Achaby, M. Malha, M. O. Bensalah, O. Fassi-Fehri, R. Bouhfid, K. Benmoussa, and A. Qaiss, Mater. Des., 43, 200 (2013).

M. Asim, M. Jawaid, K. Abdan, and M. R. Ishak, J. Bionic. Eng., 13, 426 (2016).

S. K. Ramamoorthy, M. Skrifvars, and A. Persson, Polym. Rev, 55, 107 (2015).

S. Taj, M. A. Munawar, and S. Khan, Proc. Pakistan Acad. Sci., 44, 129 (2007).

H. Wang, G. Xian, and H. Li, Compos. Part A: Appl. Sci. Manuf., 76, 172 (2015).

V. K. Thakur, A. S. Singha, and I. K. Mehta, Int. J. Polym. Anal. Charact., 15, 137 (2010).

M. Sood and G. Dwivedi, Egypt. J. Petrol., 27, 775 (2018).

D. Sedan, C. Pagnoux, A. Smith, and T. Chotard, J. Eur. Ceram. Soc., 28, 183 (2008).

C. Elanchezhian, B. V. Ramnath, G. Ramakrishnan, M. Rajendrakumar, V. Naveenkumar, and M. K. Saravanakumar, Mater. Today: P, 5, 1785 (2018).

M. R. Bambach, Compos. Struct., 210, 57 (2019).

A. Hallonet, E. Ferrier, L. Michel, and B. Benmokrane, Constr. Build. Mater., 205, 679 (2019).

L. Yan, N. Chouw, and K. Jayaraman, Compos. Part B: Eng., 56, 296 (2014).

C. Baley, A. Le Duigou, A. Bourmaud, and P. Davies, Compos. Part A: Appl. Sci. Manuf., 43, 1226 (2012).

Z. N. Azwa, B. F. Yousif, A. C. Manalo, and W. Karunasena, Mater. Des., 47, 424 (2013).

M. Ramesh, Prog. Mater Sci., 102, 109 (2019).

J. L. Thomason, Polym. Compos., 31, 1525 (2010).

X. Wang, M. Petrů, and H. Yu, Constr. Build. Mater., 208, 220 (2019).

S. Ben Abdallah, M. Teixeira, I. Chala, B. Otazaghine, R. Sonnier, C. Longuet, J.-C. Roux, and S. Rouif, Ind. Crop. Prod., 132, 430 (2019).

Y. Li, C. Chen, J. Xu, Z. Zhang, B. Yuan, and X. Huang, J. Mater. Sci., 50, 1117 (2015).

M. Foruzanmehr, L. Boulos, P. Y. Vuillaume, S. Elkoun, and M. Robert, Cellulose, 24, 1529 (2017).

M. Foruzanmehr, P. Y. Vuillaume, S. Elkoun, and M. Robert, Mater. Des., 106, 295 (2016).

J. C. Li, X. W. Chen, and F. L. Huang, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 652, 145 (2016).

H. Wang, L. Yang, H. Guo, Y. Zhao, and J. Zhao, Fiber. Polym., 20, 1266 (2019).

H. Wang, G. Xian, H. Li, and L. Sui, Fiber. Polym., 15, 1029 (2014).

V. Prasad, M. A. Joseph, K. Sekar, and M. Ali, Mater. Today: P., 5, 24862 (2018).

V. Prasad, K. Sekar, S. Varghese, and M. A. Joseph, Compos. Part A: Appl. Sci. Manuf., 124, 105505 (2019).

V. Prasad, M. A. Joseph, and K. Sekar, Compos. Part A: Appl. Sci. Manuf., 115, 360 (2018).

Acknowledgements

The research in this paper has been supported by the Fundamental Research Funds for the Central Universities of China (Grant No. 2572019BJ01), National Natural Science Foundation of China (Grant No. 51708092) and China Postdoctoral Science Fund Project (Grant No. 2018M631894).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Wu, H., Yang, L. et al. Mechanical and Interfacial Properties of Flax Fiber-reinforced Plastic Composites Based on a Chemical Modification Method. Fibers Polym 21, 1498–1507 (2020). https://doi.org/10.1007/s12221-020-9782-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9782-2