Abstract

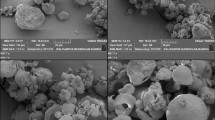

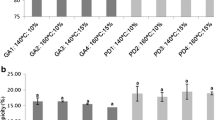

Chinese gallnut (Galla chinensis) is rich in hydrolyzable tannins, which, when mordanted with ferrous ions, produces intense black color on keratinous fiber and makes it a desirable natural hair dye in Asian countries. However, extracted tannins from Chinese gallnut are susceptible to chemical degradation by physicochemical factors (heat, UV, and high pH) that limited the utilization and commercialization of this plant colorant in color cosmetics. Hence, this study was aimed to improve the storage and application stability of Chinese gallnut extract by spray-drying microencapsulation. Different combinations of maltodextrin (MD) and gum arabic (GA) were used as encapsulating agents and the effects on the encapsulation efficiency, morphology, physicochemical properties, in vitro toxicity, and stability were investigated. The results showed that an increase of MD proportions in the wall matrix resulted in the production of more spherical shaped particles with larger size, decreased bulk density, and improved solubility in water. Furthermore, microcapsules covered with MD alone showed the maximum stability with respect to heat, UV, and formulation at alkaline pH. When applied for dyeing of human gray hairs, intense black color could be achieved by using the MD-covered microcapsule formulations and the dyeings are stable to multiple washings and simulated sunlight. Therefore, this study examines a promising strategy for stabilizing tannin-rich extract from Chinese gallnut while maintaining its dyeing efficiency, which will in turn promote its utilization in hair coloring cosmetics.

Similar content being viewed by others

References

C. X. Zhang, X. D. Tang, and J. A. Cheng, Entomol. Res., 38, S38 (2010).

B. Zhang, W. Lu, L. Luo, and M. W. King, J. Cleaner Prod., 80, 204 (2014).

N. Y. Sariozlu and M. Kivanc in “Nuts and Seeds in Health and Disease Prevention” (V. R. Preedy, R. R. Watson, and V. B. Patel Eds.), Academic Press, San Diego, 2011.

M. Shahid, A. Ahmad, M. Yusuf, M. I. Khan, S. A. Khan, N. Manzoor, and F. Mohammad, Dyes Pigm., 95, 53 (2012).

CFDA, “Safety and Technical Standards for Cosmetics”, Beijing, 2015.

I. Volf and I. Ignat, Chem. Pap., 68, 121 (2014).

M. Friedman and H. S. Jürgens, J. Agric. Food Chem., 48, 2101 (2000).

C. Saénz, S. Tapia, J. Chavez, and P. Robert, Food Chem., 114, 616 (2009).

G. L. Nunes, B. C. B. Boaventura, S. S. Pinto, S. Verruck, F. S. Murakami, and E. S. Prudêncio, J. Food Eng., 151, 60 (2015).

V. B. de Souza, A. Fujita, M. Thomazini, E. R. da Silva, J. F. Lucon, M. I. Genovese, and C. S. Favaro-Trindade, Food Chem., 164, 380 (2014).

V. A. Papillo, M. Locatelli, F. Travaglia, M. Bordiga, C. Garino, M. Arlorio, and J. D. Coïsson, Food Chem., 269, 603 (2018).

A. Tolun, Z. Altintas, and N. Artik, J. Biotechnol., 239, 23 (2016).

L. Medina-Torres, E. García-Cruz, F. Calderas, R. G Laredo, G. Sánchez-Olivares, J. Gallegos-Infante, N. Rocha-Guzmán, and J. Rodriguez-Ramirez, LWT Food Sci. Technol., 50, 642 (2013).

S. Ersus and U. Yurdagel, J. Food Eng., 80, 805 (2007).

Y. Hu, Y. Li, W. Zhang, G. Kou, and Z. Zhou, Food Hydrocolloids, 77, 588 (2018).

Y. Li, L. Wu, M. Weng, B. Tang, P. Lai, and J. Chen, Powder Technol., 340, 459 (2018).

AOAC, “Official Methods of Analysis of AOAC International”, 18th ed., AOAC International, Gaithersburg, MD, 2005.

C. B. Fritzen-Freire, E. S. Prudêncio, R. D. M. C. Amboni, S. S. Pinto, A. N. Negrão-Murakami, and F. S. Murakami, Food Res. Int., 45, 306 (2012).

ECVAM, “DB-ALM Protocol No. 96: Hen’s Egg Test on the Chorioallantoic Membrane (HET-CAM)”, 2007.

Y. Tang, W. He, Y. Wu, and R. Cai, J. Cosmet. Dermatol., doi:https://doi.org/10.1111/jocd.12879 (2019).

Y. R. Kang, Y. K. Lee, Y. J. Kim, and Y. H. Chang, Food Chem, 272, 337 (2019).

P. Boonsong, N. Laohakunjit, and O. Kerdchoechuen, J. Cleaner Prod., 37, 93 (2012).

A. M. Kalušević, S. M. Lević, B. R. Čalija, J. R. Milić, V. B. Pavlović, B. M. Bugarski, and V. A. Nedović, J. Food Sci. Technol, 54, 3411 (2017).

P. Robert, T. Gorena, N. Romero, E. Sepulveda, J. Chavez, and C. Saenz, Int. J. Food Sci. Technol., 45, 1386 (2010).

A. Tsali and A. M. Goula, Powder Technol., 340, 194 (2018).

J. Loksuwan, Food Hydrocolloids, 21, 928 (2007).

M. Paini, B. Aliakbarian, A. A. Casazza, A. Lagazzo, R. Botter, and P. Perego, LWTFood Sci. Technol., 62, 177 (2015).

M. Ahmad, P. Mudgil, A. Gani, F. Hamed, F. A. Masoodi, and S. Maqsood, Food Chem., 270, 95 (2019).

S. Çakar, N. Güy, M. Özacar, and F. Findik, Electrochim. Acta, 209, 407 (2016).

L. Laghi, G. P. Parpinello, D. D. Rio, L. Calani, A. U. Mattioli, and A. Versari, Food Chem., 121, 783 (2010).

L. Zhang, X. Zeng, N. Fu, X. Tang, Y. Sun, and L. Lin, Food Res. Int., 106, 383 (2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51403006) and the Support Project of High-level Teachers in Beijing Municipal Universities in the Period of 13th Five-year Plan (CIT&TCD201704043). The authors were also grateful to Mr. Bai Xingkun who generously donated his hair for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Y., Yang, S., He, W. et al. Stabilization of Chinese Gallnut (Galla Chinensis) Tannins by Spray-Drying Microencapsulation for Natural Hair Coloring. Fibers Polym 21, 1283–1292 (2020). https://doi.org/10.1007/s12221-020-9634-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9634-0