Abstract

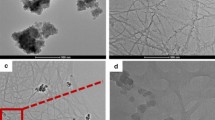

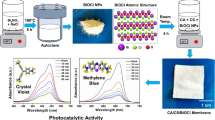

Currently, the preparation of novel efficient and recyclable photocatalysts for pollutant degradation in water has become a research hotpot. In this study, a TiO2-loaded non-woven polypropylene/bacterial cellulose (TiO2-loaded NPBC) composite film was prepared by a biological culturing method. The TiO2 nanoparticles were spontaneously embedded into the prepared composite film. Then, the composite film was used to degrade methylene blue (MB) and its degradation effects were explored. The morphology of the composite film was investigated. It was clear that a large amount of TiO2 nanoparticles were embedded into the composite membrane during the biological culturing method. The experimental results confirmed that the TiO2-loaded NPBC composite film had good degradation performance and reusability. When the reaction time was 120 min, the removal rate of MB by the film was 92.8 %. The removal rate remained above 85 % after 5 degradation cycles.

Similar content being viewed by others

References

A. Ramazani, M. Oveisi, M. Sheikhi, and F. Gouranlou, Curr. Org. Chem., 13, 1298 (2018).

L. C. Castillo-Carvajal, J. L. Sanz-Martin, and B. E. Barragan-Huerta, Environ. Sci. Pollut. Res., 16, 9580 (2014).

J. Infant, S. Aishwarya, and T. Sivakumar, J. Nanosci. Nanotechnol., 19, 2575 (2019).

L. Carmine, A. Ancona, and K. Cesare, Appl. Catal., B, 243, 632 (2019).

Y. Qu and X. Duan, Chem. Soc. Rev., 42, 2569 (2013).

D. Gao, N. Liu, W. Li, and Y. Han, Appl. Organomet. Chem., 3, 2 (2018).

A. Khalil, N. Aboamerab, W. Nasserc, W. Mahmoudd, and G. Mohamed, Sep. Sci. Technol., 224, 510 (2019).

M. Mohameda, W. A. Bayoumya, T. Y. Mansour El-Ashkar, M. E. Goher, and M. H. Abho, J. Environ. Chem. Eng., 7, 102884 (2019).

D. Huang, Z. Mo, and S. Quan, Acta Mater., 33, 155 (2016).

Z. Wang, Y. Li, and B. Liu, J. Synth. Cryst., 45, 2640 (2016).

D. Zhao, Y. Wang, and Z. Han, Rare Metal Mat. Eng., 44, 608 (2016).

J. Miao, F. Zeng, and L. Guan, Acta Photonica Sinica, 47, 101 (2018).

J. Gutierrez, A. Tercjak, and I. Algar, J. Collold Interf. Sci., 47, 100 (2018).

Q. Feng, Y. Qian, and S. Huan, J. Donghua Uni. Natural Sci., 44, 30 (2018).

G. Li, A. G. Nandgaonkar, and Q. Wang, J. Membrane Sci., 525, 89 (2017).

J. Wua, Y. Zheng, W. Song, J. Luan, and X. Wen, Carbohydr. Polym., 102, 764 (2014).

L. Chen, M. Zou, and F. Hong, Front. Microblol., 6, 3 (2015).

R. Brandes, E. Trindade, D. Vanin, and V. Vargas, Fiber. Polym., 19, 1862 (2018).

A. Khalid, H. Ullah, and M. Ul-Islam, RSC Adv., 7, 47662 (2017).

Z. Zhu, X. Li, and D. Wu, J. Anhui Uni. Eng., 32, 28 (2017).

J. Huang, P. Lv, and Y. Yao, J. Text. Res., 39, 127 (2018).

F. Ye, L. Li, and L. Zhang, ACS Appl. Mater. Interfaces, 6, 5106 (2014).

C. Zhou, Y. Li, and Y. Ma, J. Text. Res., 39, 91 (2018).

K. Ao, D. Li, and Y. Yao, Chin. J. Mater. Res., 32, 157 (2018).

J. Feng, Y. Duan, and Y. Jiao, Acta Phys-Chim. Sin., 12, 1433 (2005).

M. Kheirabadi, M. Samadi, E. Asadian, Y. Zhou, C. Dong, J. Zhang, and A. Z. Moshfegh, J. Colloid Interface Sci., 537, 70 (2019).

A. Uheida, A. Mohamed, M. Belaqziz, and W. S. Nasser, Sep. Purif. Technol., 212, 111 (2019).

X. Wang, Y. Sun, L. Yang, Q. Shang, D. Wang, T. Guo, and Y. Guo, Sci. Total Environ., 656, 1011 (2019).

G. Zhang, D. Wang, J. Yan, Y. Xiao, W. Fu, and C. Zang, Materials, 12, 5 (2019).

K. Paul, R. Ghosh, and P. Giri, Nanotechnology, 27, 11 (2016).

Z. Kadirova, M. Hojamberdiev, K. Katsumata, T. Isobe, N. Matsushita, A. Nakajima, and K. Okada, Environ. Sci. Pollut. Res, 21, 4314 (2014).

Acknowledgments

This work was funded by the International Cooperation Project of Anhui Province in China (1604b0602024), “Textile fabric” key Laboratory of Anhui University and Opening Fund Project of Anhui Textile Engineering Technology Research Center (KZ00418043). The authors are thankful for the support from the Department of Education in Anhui Province of China (KJ2016SD04 and 2015LJRCTD001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Wu, D., Feng, Q. et al. Soft High-Loading TiO2 Composite Biomaterial Film as an Efficient and Recyclable Catalyst for Removing Methylene Blue. Fibers Polym 21, 1760–1766 (2020). https://doi.org/10.1007/s12221-020-9543-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9543-2