Abstract

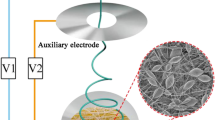

At present, there exists a widely-held view that electric field plays an extremely important role in the electrospray process. Aimed at investigating into the effects of electric field distribution and intensity on the electrospray process and resultant microsphere diameter, a variety of necessary and relevant tests were performed in this study by inviting an auxiliary electrode ring. The three-dimensional electric fields of the electrospray system were simulated, in addition, high-speed photography was adopted to recognize the electrospray modes. The results of a series of electrospray experiments demonstrated that not only electrospray mode but also resultant microsphere diameters are influenced, to a considerable degree, by the electric field. Such simulation results were verified by above-mentioned experiments that from higher electric field intensity comes smaller microsphere diameter, due to the fission caused by the surface charge, and besides, more uniform electric field distribution produces more uniform microsphere diameter.

Similar content being viewed by others

References

Y. X. Yin, S. Xin, L. J. Wan, C. J. Li, and Y. G. Guo, J. Phys. Chem. C, 115, 14148 (2011).

G. M. Liang, X. Y. Qin, J. S. Zou, L. Y. Luo, Y. Z. Wang, M. Y. Wu, H. Zhu, G. H. Chen, F. Y. Kang, and B. H. Li, Carbon, 127, 424 (2018).

G. L. Fillmore, W. L. Buehner, and D. L. West, Ibm. J. Res. Dev., 21, 37 (1977).

J. J. Ahire and L. M. T. Dicks, Curr. Microbiol., 73, 236 (2016).

Y. H. Lee, F. Mei, M. Y. Bai, S. L. Zhao, and D. R. Chen, J. Control Release, 145, 58 (2010).

R. Sridhar and S. Ramakrishna, Biomatter, 3, e24281 (2013).

T. H. Hwang, J. B. Kim, D. S. Yang, Y. I. Park, and W. H. Ryu, J. Micromech. Microeng., 23, 035012 (2013).

H. Fong, I. Chun, and D. H. Reneker, Polymer, 40, 4585 (1999).

R. Ambrus, N. Radacsi, T. Szunyogh, E. D. M. Antoine, van der Heijden, J. H. Ter Horst, and P. Szabó-Révész, J. Pharmaceut. Biomed., 76, 1 (2013).

P. Nemes, I. Marginean, and A. Vertes, Anal. Chem., 79, 3105 (2007).

K. Q. Tang and A. Gomez, Phys. Fluids, 6, 404 (1994).

S. Ogata, T. Hatae, K. Shoguchi, and H. Shinohara, Kagaku Kogaku, 3, 132 (1977).

J. W. Xie, J. Jiang, P. Davoodi, M. P. Srinivasan, and C. H. Wang, Chem. Eng. Sci., 125, 32 (2015).

H. B. Zhang, M. J. Edirisinghe, and S. N. Jayasinghe, J. Fluid. Mech., 558, 103 (2006).

B. Q. T. Si, D. Byun, and S. Lee, J. Aerosol. Sci., 38, 924 (2007).

M. W. Chang, E. Stride, and M. Edirisinghe, J. R. Soc. Interface, 7, 451 (2010).

S. H. Hong, J. H. Moon, J. M. Lim, S. H. Kim, and S. M. Yang, Langmuir, 21, 10416 (2005).

S. Neubert, D. Pliszka, A. Góra, A. Jaworek, E. Wintermantel, and S. Ramakrishna, J. Appl. Polym. Sci., 125, 820 (2012).

B. Almería and A. Gomez, J. Colloid Interf. Sci., 417, 121 (2014).

Y. Yang, Z. D. Jia, Q. Li, L. Hou, J. M. Liu, L. Wang, and Z. C. Guan, IEEE T. Dielect. El. In., 17, 1592 (2010).

J. Ponce, S. Sullivan, A. Sudsang, J. D. Boissonnat, and J. P. Merlet, Int. J. Robot. Res., 16, 11 (1997).

A. Jaworek, A. T. Sobczyk, and A. Krupa, J. Aerosol. Sci., 125, 57 (2018).

Y. S. Zheng and Y. C. Zeng, J. Mater. Sci., 49, 1964 (2014).

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 11702169), and Talents Action Program of Shanghai University of Engineering Science (Grant No. 2017RC522017) to Dr. Y. Zheng. This work was also supported by Talents Action Program of Shanghai University of Engineering Science (Grant No. 2017RC432017) and Shanghai Local Capacity-Building Project (Grant No. 19030501200) to Dr. B. Xin.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, X., Zheng, Y., Xin, B. et al. Effects of Electric Filed on Electrospray Process: Experimental and Simulation Study. Fibers Polym 21, 2695–2705 (2020). https://doi.org/10.1007/s12221-020-1200-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-1200-2