Abstract

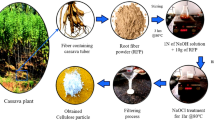

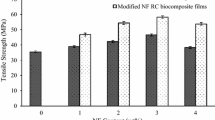

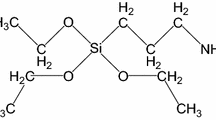

Cassava bagasse contains considerable amount of natural single elementary cellulose fibers and white thick root fiber (thick-core fiber) that has seen frequent application in the packaging industry as reinforcement for plastic composite development. However, a review of the literature was unable to find any study that characterized the material properties (such as tensile properties) of both the single elementary and white thick-core cassava cellulose fibers), and their application as potential reinforced filler in tissue engineering scaffold development. In this study, the tensile properties, morphology, crystallinity and thermal degradation profile of non-chemically treated single elementary cellulose fibers and thick-core fibers of different cassava genotypes were investigated. Fibers were tested according to ASTM C1557 under direct tension in a standard mechanical testing system and the cross-sectional area of the fractured regions of the fibers were determined using a 3D optical microscopy method. Cassava fibers of different genotypes did not show any significant difference in tensile properties, with average tensile strength ranging from (5.1–7.3 MPa), Young’s modulus (258–333 MPa) and failure strain (3.4–4.2 %). Tensile test conducted for several gage lengths did not influence the tensile strength and Young’s modulus of the fibers, however, strain-at-break depended on gage length. Single elementary and thick-core fibers showed similar surface morphology, degree of crystallinity (ranging from 21–40 %) and tensile properties with some variation in elastic modulus. Cassava fibers are thermally stable around 100–200 oC, where processing could be performed. Preliminary results showed an improvement in the mechanical properties of a gelatin scaffold when cassava cellulose microfibers were used as reinforcing fillers. The current findings show that cassava fiber has a reasonable mechanical strength, stiffness and thermal stability, and could be considered as a reinforced biomaterial to improve the mechanical integrity of tissue engineering scaffolds.

Similar content being viewed by others

References

A. Edhirej, S. M. Sapuan, M. Jawaid, and N. I. Zahari, Polym. Compos., 38, 555 (2017).

N. J. Tonukari, J. Biotechnol., 7, 12 (2004).

D. R. Lu, C. M. Xiao, and S. J. Xu, Express Polym. Lett., 3, 366 (2009).

K. W. Kim, B. H. Lee, H. J. Kim, K. Sriroth, and J. R. Dorgan, J. Therm. Anal. Calorim., 108, 1131 (2011).

J. Sunthornvarabhas, P. Chatakanonda, K. Piyachomkwan, and K. Sriroth, Mater. Lett., 65, 985 (2011).

E. D. M. Teixeira, D. Pasquini, A. A. S. Curvelo, E. Corradini, M. N. Belgacem, and A. Dufresne, Carbohydr. Polym., 78, 422 (2009).

E. D. M. Teixeira, A. A. S. Curvelo, A. C. Corrêa, J. M. Marconcini, G. M. Glenn, and L. H. C. Mattoso, Ind. Crops Prod., 37, 61 (2012).

A. Pandey, C. R. Soccol, P. Nigam, V. T. Soccol, L. P. S. Vandenberghe, and R. Mohan, Bioresour. Technol., 74, 81 (2000).

K. N. Matsui, F. D. S. Larotonda, S. S. Paes, D. B. Luiz, A. T. N. Pires, and J. B. Laurindo, Carbohydr. Polym., 55, 237 (2004).

A. Célino, S. Fréour, F. Jacquemin, and P. Casari, Front. Chem., 1, 43 (2014).

C. C. Egbeocha, S. N. Asoegwu, and N. A. A. Okereke, FUTOJNLS, 2, 140 (2016).

E. Hermiati, D. Mangunwidjaja, T. C. Sunarti, O. Suparno, and B. Prasetya, Sci. Res. Essays., 7, 100 (2012).

K. Sriroth and K. Sangseethong, Acta Hortic., 703, 145 (2006).

D. Pasquini, E. D. M. Teixeira, A. A. D. S. Curvelo, M. N. Belgacem, and A. Dufresne, Ind. Crops Prod., 32, 486 (2010).

R. Wicaksono, K. Syamsu, I. Yuliasih, and M. Nasir, Chem. Mater. Res., 3, 79 (2013).

F. O. Farias, A. C. Jasko, T. A. D. Colman, L. A. Pinheiro, E. Schnitzler, A. C. Barana, and I. M. Demiate, Brazilian Arch. Biol. Technol., 57, 821 (2014).

A. Edhirej, S. M. Sapuan, M. Jawaid, and N. I. Zahari, Fiber. Polym., 18, 162 (2017).

S. M. Lien, L. Y. Ko, and T. J. Huang, Acta Biomater., 5, 670 (2009).

F. Asghari, M. Samiei, K. Adibkia, A. Akbarzadeh, and S. Davaran, Artif. Cells, Nanomedicine Biotechnol., 45, 185 (2017).

Q. L. Loh and C. Choong, Tissue Eng. Part B Rev., 19, 485 (2013).

E. Entcheva, H. Bien, L. Yin, C. Y. Chung, M. Farrell, and Y. Kostov, Biomaterials, 25, 5762 (2004).

Q. Xing, F. Zhao, S. Chen, J. McNamara, M. A. DeCoster, and Y. M. Lvov, Acta Biomater., 6, 2132 (2010).

I. K. Ko and H. Iwata, Ann. N. Y. Acad. Sci., 944, 443 (2001).

P. Pooyan, R. Tannenbaum, and H. Garmestani, J. Mech. Behav. Biomed. Mater., 7, 50 (2012).

ASTM C1557–14, Standard Test Method for Tensile Strength and Young’s Modulus of Fibers, ASTM International, West Conshohocken, PA, www.astm.org, 2014.

L. Segal, J. J. Creely, A. E. Martin, and C. M. Conrad, Text. Res. J., 29, 786 (1959).

F. A. Silva, N. Chawla, and R. D. T. Filho, J. Biobased Mater. Bioenergy, 4, 106 (2010).

M. E. A. Fidelis, T. V. C. Pereira, O. D. F. M. Gomes, F. D. Andrade Silva, and R. D. T. Filho, J. Mater. Res. Technol., 2, 149 (2013).

F. Tomczak, K. G. Satyanarayana, and T. H. D. Sydenstricker, Compos. Part A Appl. Sci. Manuf., 38, 2227 (2007).

F. A. Silva, N. Chawla, and R. D. T. Filho, Compos. Sci. Technol., 68, 3438 (2008).

W. Hu, M. T. Ton–That, F. Perrin–Sarazin, and J. Denault, Polym. Eng. Sci., 50, 819 (2010).

F. Versino, O. V. López, and M. A. García, Ind. Crops Prod., 65, 79 (2015).

M. Wada and T. Okano, Cellulose, 8, 183 (2001).

M. Poletto, H. L. Ornaghi Júnior, and A. J. Zattera, Materials, 7, 6105 (2014).

A. L. M. P. Leite, C. D. Zanon, and F. C. Menegalli, Carbohydr. Polym., 157, 962 (2017).

Z. Xiang, R. Liao, M. S. Kelly, and M. Spector, Tissue Eng., 12, 2467 (2006).

L. A. Smith, J. A. Beck, and P. X. Ma, “Nanofibrous Scaffolds and their Biological Effects”, in: Nanotechnologies Life Sci., Online, 2007.

V. Tserki, P. Matzinos, S. Kokkou, and C. Panayiotou, Compos. Part A Appl. Sci. Manuf., 36, 965 (2005).

H. S. Kim, S. Kim, H. J. Kim, and H. S. Yang, Thermochim. Acta, 451, 181 (2006).

B. Pei, W. Wang, Y. Fan, X. Wang, F. Watari, and X. Li, Regen. Biomater., 4, 257 (2017).

S. Yang, K. F. Leong, Z. Du, and C. K. Chua, Tissue Eng., 8, 1 (2002).

Food and Agriculture Organization of the United Nations. Trade and Markets Division. Food Outlook: Biannual Report on Global Food Markets, October 2014. Food and Agriculture Organization of the United Nations, 2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Diabor, E., Funkenbusch, P. & Kaufmann, E.E. Characterization of Cassava Fiber of Different Genotypes as a Potential Reinforcement Biomaterial for Possible Tissue Engineering Composite Scaffold Application. Fibers Polym 20, 217–228 (2019). https://doi.org/10.1007/s12221-019-8702-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-8702-9