Abstract

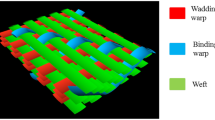

In this research work, multi layered (2, 3 and 5 layers) hybrid as well as uni-polymer flexible composites based on high performance fabrics such as Aramid (Kevlar) and UHMWPE (Ultra high molecular weight polyethylene) for ballistic applications were prepared. The composites were prepared by compression molding technique by using sheets of Low density polyethylene (LDPE) in between two adjacent fabric layers. All Kevlar, all UHMDPE and hybrid (combination of Kevlar and UHMDPE) composites were prepared. The temperature selected was such that it resulted in melting of LDPE sheets but did not affect UHMWPE fabric. Corresponding multilayered stitched samples were also prepared and the two were tested for tensile, impact and peel strength. It was found that the composites samples performed better than corresponding stitched samples in tensile and impact testing. Among the composites, samples with Kevlar fabrics showed higher impact energy absorption than all UHMWPE and hybrid. However, all UHMWPE and hybrid composites exhibited higher peak force and energy till failure. This was attributed to better bonding between the fabric layers by LDPE in case of all UHMWPE composites. In case of all Kevlar samples, poor bonding resulted in yarn pull out and reduced peak total energy absorption and peak force.

Similar content being viewed by others

References

Y. S. Lee, E. D. Wetzel, and N. J. Wagner, J. Mater. Sci., 38, 2825 (2003).

R. G. Egres, Y. S. Lee, J. E. Kirkwood, K. M. Kirkwood, E. D. Wetzel, and N. J. Wagner, 14th International Conference on Composite Materials, San Diego, CA, July 14 (2003).

D. P. Kalman, R. L. Merrill, N. J. Wagner, and E. D. Wetzel, Appl. Mater. Interfaces, 1, 2602 (2009).

D. P. Kalman, J. B. Schein, C. H. N. E. Laufer, D. Wetzel, and N. J. Wagner, Proceedings of SAMPE 2007, Baltimore, MD, June 3-7 (2007).

Y. S. Lee, E. D. Wetzel, R. G. Egres, and N. J. Wagner, 23rd Army Science Conference, Orlando, FL. December 2-5, 1 (2002).

E. D. Wetzel, Y. S. Lee, R. G. Egres, K. M. Kirkwood, J. E. Kirkwood, and N. J. Wagner, Numiform, June 13-17, 1 (2004).

A. Majumdar, B. S. Butola, A. Srivastava, D. Bhattacharya, I. Biswas, A. Laha, S. Arora, and A. Ghosh, Fiber. Polym., 17, 199 (2016).

A. Majumdar, B. S. Butola, and A. Srivastava, Mater. Des., 54, 195 (2014).

A. Srivastava, A. Majumdar, and B. S. Butola, Mater. Des., 51, 148 (2013).

A. Majumdar, B. S. Butola, and A. Srivastava, Mater. Des., 46, 191 (2013).

A. Srivastava, A. Majumdar, and B. S. Butola, Critical Reviews in Solid State and Mater. Sci., 37, 115 (2012).

A. Srivastava, A. Majumdar, and B. S. Butola, Mater. Sci. Eng. A, 529, 224 (2011).

K. S. Pandya, J. R. Pothnis, G. Ravikumar, and N. K. Naik, Mater. Des., 44, 128 (2013).

F. Sarasini, J. Tirillo, M. Valente, L. Ferrante, S. Cioffi, S. Iannace, and L. Sorrentino, Mater. Des., 49, 290 (2013).

M. T. Dehkordi, H. Nosraty, S. M. Mahmood, G. Minak, and D. Ghelli, Mater. Des., 43, 283 (2013).

N. J. Capiati and R. S. Porter, J. Mater. Sci., 10, 1671 (1975).

P. J. Hine, I. M. Ward, R. H. Olley, and D. C. Bassett, J. Mater. Sci., 28, 316 (1993).

R. H. Olley, D. C. Bassett, P. J. Hine, and M. Ward, J. Mater. Sci., 28, 1107 (1993).

X. Wang and R. Salovey, J. Appl. Polym. Sci. 34, 593 (1987).

W. T. Mead and S. Porter, J. Appl. Polym. Sci. 22, 3249 (1978).

P. Dai, W. Zhang, Y. Pan, J. Chen, Y. Wang, and D. Yao, Compos. Pt. B-Eng., 42, 1144 (2011).

S. Fakirov, Compos. Sci. Technol., 89, 211 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Butola, B.S., Majumdar, A., Jain, A. et al. Multilayered flexible uni-polymer and hybrid composites for ballistic applications. Fibers Polym 18, 786–794 (2017). https://doi.org/10.1007/s12221-017-6959-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-6959-4