Abstract

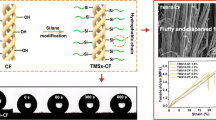

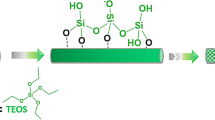

Hyperbranched polymers, an innovative class of nano-polymers, could enhance the properties of fibers owning to their unique structures. In this study, the ester compound (HPAE) of 3-(bis(2-hydroxyethyl)amino)propionic acid and pentaerythritol was treated with undecylenic acid to obtain novel hyperbranched multiterminal alkenyl polymers (HPAE-UAs). The sizes of the HPAE-UAs could be controlled conveniently from 400 to 1300 nm by adjusting the capped fraction of the hydroxyl groups with undecylenic acids. The molecular structures of HPAE-UAs were characterized by means of FT-IR and 1H-NMR. Then, the effect of the HPAE-UAs on the structures, thermal, and mechanical properties of the wet blue leather were investigated. TEM and SEM demonstrated that the spacing between fibers was enlarged. The thermogravimetric analysis showed that the residual volume of leather could reach up to 30.3 % at about 500 °C. Furthermore, the shrinkage temperature increased to 89.4 °C. It was found that the HPAE-UAs used in leather could improve the thermal performance, physical and mechanical properties. All of these results indicate that HPAE-UAs can be used as a fatliquor with retanning in leather process.

Similar content being viewed by others

References

J. Du, L. Shi, and B. Peng, J. Appl. Polym. Sci., 133, 43440 (2016).

Z. Bajza and I. V. Vrcek, J. Mater. Sci., 36, 5265 (2001).

M. Adeli, B. Rasoulian, F. Saadatmehr, and F. Zabihi, J. Appl. Polym. Sci., 129, 3665 (2013).

J. Borah and N. Karak, J. Appl. Polym. Sci., 104, 648 (2007).

S. Li, Q. Lin, H. Zhu, C. Cui, H. Hou, T. Lv, and Y. Li, Fiber. Polym., 17, 282 (2016).

Y. Liu, C. Yu, H. Jin, B. Jiang, X. Zhu, Y. Zhou, and D. A. Yan, J. Am. Chem. Soc., 135, 4765 (2013).

S. R. Madeshwaran, J. K. Kwon, and J. W. Cho, Fiber. Polym., 14, 182 (2013).

W. J. Yang, K. G. Neoh, E. T. Kang, S. L. Teo, and M. D. Rittschof, Polym. Chem., 4, 3105 (2013).

L. F. Ren, N. Wang, and X. C. Wang, J. Appl. Polym. Sci., 132, 41383 (2015).

Y. Zhao and J. C. Wang, J. Appl. Polym. Sci., 128, 2385 (2013).

J. Borah and N. Karak, J. Appl. Polym. Sci., 104, 648 (2007).

T. T. Qiang, G. G. Zhang, and M. Luo, Fine Chemicals (China), 2012, 692 (2012).

Y. Kitajyo, T. Imai, Y. Sakai, M. Tamaki, H. Tani, K. Takahashi, and T. Kakuchi, Polymer, 48, 1237 (2007).

H. Mori, D. C. Seng, M. Zhang, and A. H. Müller, Langmuir, 18, 3682 (2002).

S. F. Shiau, T. Y. Juang, H. W. Chou, and M. Liang, Polymer, 54, 623 (2013).

T. Sato, T. Nakamura, M. Seno, and T. Hirano, Polymer, 47, 4630 (2006).

H. Tian, C. Deng, H. Lin, J. Sun, M. Deng, X. Chen, and X. Jing, Biomaterials, 26, 4209 (2005).

S. G. An, G. H. Li, and C. G. Cho, Polymer, 47, 4154 (2006).

X. Zhai, S. Peleshanko, N. S. Klimenko, K. L. Genson, D. Vaknin, M. Y. Vortman, and V. V. Tsukruk, Macromolecules, 36, 3101 (2003).

H. Cheng, S. Wang, J. Yang, Y. Zhou, and D. Yan, J. Colloid. Interf. Sci., 337, 278 (2009).

X. X. Wang, G. Q. Lai, Z. Jiang, and Y. Zhang, Eur. Polym. J., 42, 286 (2006).

Y. Kitajyo, Y. Nawa, M. Tamaki, H. Tani, K. Takahashi, H. Kaga, and T. Kakuchi, Polymer, 48, 4683 (2007).

G. Xu and W. Shi, Prog. Org. Coat., 52, 110 (2005).

K. Sizeland, G. Holmes, R. Edmonds, N. Kirby, A. Hawley, and S. Mude, J. Am. Leather. Chem. Assoc., 110, 355 (2015).

I. P. Fernandes, J. S. Amaral, V. Pinto, M. J. Ferreira, and M. F. Barreiro, Carbohydr. Polym., 98, 1229 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Guo, X., Zhang, T. et al. Properties of polymers as a nanoscale material for fibers in leather. Fibers Polym 18, 1504–1511 (2017). https://doi.org/10.1007/s12221-017-6583-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-6583-3