Abstract

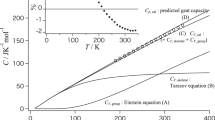

For a highly exothermic reaction, heat capacity is a critical determinant of temperature profile which impacts temperature-dependent variables such as reaction rate constants, heat of reaction, viscosity, and diffusivity. In the case of polymer-forming reactions: literally hundreds of oligomers can be present at any time, heat capacities are typically not available for most of these oligomeric monomers. The group contribution method emerges as one of the few viable approaches to make an estimate of heat capacities being a salient intermediate step toward the objective of simulating polyurethane reaction process. Based on compiled literature and supplemental DSC data, Missernard’s group contribution model was revised with alternative values to those suggested by literature and accessorial parameters for the following functional groups: a) isocyanate, b) six carbon sugar ring, c) aromatic benzene ring, and d) double-bonded oxygen of an ester to estimate heat capacities from 25 °C to 120 °C for alcohols and isocyanate present in the urethane-forming reactions. Modeling performance showed a good agreement with an overall 1.59 per cent deviation. It was also observed that the alcohol heat capacity generally decreased with the rise of molecular weight.

Similar content being viewed by others

References

R. Ghoreishi, Y. Zhao, and G. J. Suppes, J. Appl. Polym. Sci., 131, 12 (2014).

Y. Zhao, M. J. Gordon, A. Tekeei, F.-H. Hsieh, and G. J. Suppes, J. Appl. Polym. Sci., 130, 1131 (2013).

Z. Fu and G. J. Suppes, J. Polym. Eng., 35, 11 (2015).

Y. Zhao and G. J. Suppes, Polym. Eng. Sci., 55, 1420 (2015).

H. Al-Moameri, R. Ghoreishi, and G. J. Suppes, Chem. Eng. Sci., 161, 14 (2017).

R. C. Reid, J. M. Prausnitz, and B. E. Poling, “The Properties of Gases and Liquids”, 4th ed., pp.137–141, McGraw-Hill, New York, 1987.

Dow Plastics, PAPI 27 Polymeric MDI, 2001.

E. S. Domalski and E. D. Hearing, J. Phys. Chem. Ref. Data, 25, 1 (1996).

Dow Chemical Company, A Guide to Glycols, 2003.

ASTM, E1269 (2011).

ASTM, E967 (2014).

ASTM, E968 (2014).

Federation of European Rigid Polyurethane Foam Associations, Thermal Insulation Materials Made of Rigid Polyurethane Foam, 2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

An, S., Shen, L. & Suppes, G.J. Group contribution modeling of heat capacities in urethane-forming reactions. Fibers Polym 18, 1031–1039 (2017). https://doi.org/10.1007/s12221-017-1199-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-017-1199-1