Abstract

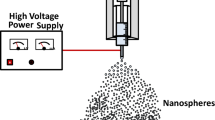

Because of a number of facilities, the Electrospray (ES) method is gaining ever-increasing popularity among researchers for producing nano-to-micron-sized particles. Microparticles (MPs) of poly lactic-co-glycolic acid (PLGA) were prepared by using the ES technique. The influence of both solution and apparatus parameters on the morphology, size, size distribution, and uniformity of produced MPs were investigated. Results of SEM images and calculations revealed that polymer concentration is a critical parameter in the ES system. In a semi-dilute moderately entangled regime, chain entanglement can easily occur. Solution flow rate is a key factor among apparatus parameters. Vapour pressure is a key parameter affecting MP morphology. The size of the particles tended to reduce with an increase in voltage. The needle gauge did not have an important impact on particle size. The role of the electric field changed at different collecting distances. Using a saturated combination of EtOH/PVA is an acceptable collecting medium for PLGA MPs. It is possible to produce uniform and spherical MPs by using chloroform as a solvent. However, a reduction in particle size is achievable by using a solvent of chloroform/DMF (90/10 w/w).

Similar content being viewed by others

References

D. Bennet and S. Kim, in “Application of Nanotechnology in Drug Delivery” (A. D. Sezer Ed.), p.257, InTech, Rijeka, 2014.

R. Mundargi, V. Babu, V. Rangaswamy, P. Patel, and T. Aminabhavi, J. Control. Release, 125, 193 (2008).

J. Hall, M. Dobrovolskaia, A. Patri, and S. McNeil, Nanomedicine (Lond.), 2, 789 (2007).

J. Bourges, S. Gautier, and E. A. F. Delie, Invest. Ophthalmol. Vis. Sci., 44, 3562 (2003).

E. D. Jalón, M. Blanco-Príeto, P. Ygartua, and S. Santoyo, Int. J. Pharm., 226, 181 (2001).

E. M. Shapiro, Magn. Reson. Med., 73, 376 (2015).

H. K. Makadia and S. J. Siegel, Polymers, 3, 1377 (2011).

E. H. Gang, C. S. Ki, J. W. Kim, J. Lee, B. G. Cha, K. H. Lee, and Y. H. Park, Fiber. Polym., 13, 685 (2012).

F. Zamani, M. Latifi, M. Amani-Tehran, and M. A. Shokrgozar, Fiber. Polym., 14, 698 (2013).

F. Haghighat and S. A. H. Ravandi, Fiber. Polym., 15, 71 (2014).

S. Mahalingam, Z. Xu, and M. Edirisinghe, Langmuir, 31, 9771 (2015).

W. Zhu, S.-J. Lee, N. J. Castro, D. Yan, M. Keidar, and L. G. Zhang, Sci. Rep., 6, 21974 (2016).

R. Bagherzadeh, S. S. Najar, M. Latifi, M. A. Tehran, and L. Kong, J. Biomed. Mater. Res. Part A, 101A, 2107 (2013).

A. Gheibi, M. Latifi, A. A. Merati, and R. Bagherzadeh, J. Polym. Res., 21, 469 (2014).

R. Bagherzadeh, M. Latifi, S. S. Najar, M. A. Tehran, and M. G. A. L. Kong, Text. Res. J., 82, 70 (2011).

N. Bock, M. A. Woodruff, D. W. Hutmacher, and T. R. Dargaville, Polymers, 3, 131 (2011).

R. Bagherzadeh, M. Latifi, and L. Kong, J. Biomed. Mater. Res. Part A, 102, 903 (2013).

H. Fu, Q. Liu, and D.-R. Chen, J. Aerosol Sci., 52, 33 (2012).

Y. Wu and R. L. Clark, J. Colloid Interface Sci., 310, 529 (2007).

L. M. M. Costa, R. E. S. Bretas, and J. Rinaldo Gregorio, Mater. Sci. Appl., 1, 247 (2010).

N. Bock, T. R. Dargaville, and M. A. Woodruff, Prog. Polym. Sci., 37, 1510 (2012).

M. Jafari-Nodoushan, J. Barzin, and H. Mobedi, Polym. Adv. Technol., 26, 502 (2015).

C. H. Park and J. Lee, J. Appl. Polym. Sci., 114, 430 (2009).

Y. Wu, A. Duong, L. J. Lee, and B. E. Wyslouzil, in “The Delivery of Nanoparticles” (A. A. Hashim Ed.), p.223, InTech, Rijeka, 2012.

S. Chakraborty, I.-C. Liao, A. Adler, and K. W. Leong, Adv. Drug Deliv. Rev., 61, 1043 (2009).

A. Jahangiri, M. Barzegar-Jalali, Y. Javadzadeh, H. Hamishehkar, and K. Adibkia, Artif. Cells Nanomed. Biotechnol., 13, 1 (2016).

I. M. Smallwood, “Handbook of Organic Solvent Properties”, Halsted Press, New York, 1996.

M. Jafari-Nodoushan, H. Mobedi, and J. Barzin, in “Handbook of Encapsulation and Controlled Release”, pp.413–435, CRC Press, Boca Raton, 2015.

M. Jafari-Nodoushan, J. Barzin, and H. Mobedi, J. Chromatogr. B, 1011, 163 (2016).

I. B. Rietveld, K. Kobayashi, H. Yamada, and K. Matsushige, J. Colloid Interface Sci., 298, 639 (2006).

H. Moghadam, M. Samimi, A. Samimi, and M. Khorram, Particuology, 6, 271 (2008).

M. Enayati, Z. Ahmad, E. Stride, and M. Edirisinghe, Curr. Pharm. Biotechnol., 10, 600 (2009).

Y. Xu, M. Skotak, and M. Hanna, J. Microencapsul., 23, 69 (2006).

J. Gomez-Estaca, R. G. M. P. Balaguer, and P. Hernandez-Munoz, Food Hydrocoll., 28, 82 (2012).

P. Gupta, C. Elkins, T. E. Long, and G. L. Wilkes, Polymer, 46, 4799 (2005).

W. S. Khan, R. Asmatulu, M. Ceylan, and A. Jabbarnia, Fiber. Polym., 14, 1235 (2013).

M. Parhizkar, P. J. T. Reardon, J. C. Knowles, R. J. Browning, E. Stride, R. B. Pedley, A. H. Harker, and M. Edirisinghe, Nanomed. Nanotech. Biol. Med., 12, 1919 (2016).

B. Almería, W. Deng, T. M. Fahmy, and A. Gomez, J. Colloid Interface Sci., 343, 125 (2010).

J. Xie, J. C. M. Marijnissen, and C.-H. Wang, Biomaterials, 27, 3321 (2006).

F. Imanparast, M. A. Faramarzi, M. Paknejad, F. Kobarfard, A. Amani, and M. Doosti, J. Appl. Polym. Sci., 133, 43602 (2016).

A. M. Gañán-Calvo and A. B. J. Dávila, J. Aerosol Sci., 28, 249 (1997).

R. Hartman, B. Dj, D. Camelot, J. Marijnissen, and B. Scarlett, J. Aerosol Sci., 31, 65 (2000).

G. Liu, X. Miao, W. Fan, R. Crawford, and Y. Xiao, J. Biomim. Biomater. Tissue Eng., 6, 1 (2010).

F. Bagheri-Tar, M. Sahimi, and T. T. Tsotsis, Ind. Eng. Chem. Res., 46, 3348 (2007).

Y. Hong, Y. Lib, Y. Yin, D. Lia, and G. Zou, J. Aerosol Sci., 39, 525 (2008).

X. S. Wu, in “Encyclopedic Handbook of Biomaterials and Bioengineering, Part A: Materials” (D. L. Wise, D. J. Trantolo, D. E. Altobelli, M. J. Yaszemski, J. D. Gresser, and E. R. Schwarts Eds.), pp.1037–1039, Marcel Dekker, New York, 1995.

D. Fantini, M. Zanetti, and L. Costa, Macromol. Rapid Commun., 27, 2038 (2006).

A. Bohr, M. Yang, S. Baldursdóttir, J. Kristensen, M. Dyas, E. Stride, and M. Edirisinghe, Polymer, 53, 3220 (2012).

B. Almería, T. M. Fahmy, and A. Gomez, J. Control. Release, 154, 203 (2011).

B. Almería and A. Gomez, J. Colloid Interface Sci., 417, 121 (2014).

J. D. Oxley in “Encapsulation Technologies and Delivery Systems for Food Ingredients and Nutraceuticals” (N. Garti and D. J. McClements Eds.), p.135, Woodhead Publishing Limited, Philadelphia, 2012.

J.-F. Hu, S.-F. Li, G. R. Nair, and W.-T. Wu, Chem. Eng. Sci., 82, 159 (2012).

Y. Xu and M. A. Hanna, J. Microencapsul., 24, 143 (2007).

Y. Xu and M. A. Hanna, Int. J. Pharm., 320, 30 (2006).

R. Pareta and M. J. Edirisinghe, J. R. Soc. Interface, 3, 573 (2006).

H. Valo, L. Peltonen, and E. A. S. Vehvila inen, Small, 5, 1791 (2009).

Z. Ahmad, H. B. Zhang, U. Farook, M. Edirisinghe, E. Stride, and P. Colombo, J. R. Soc. Interface, 5, 1255 (2008).

H. Nie, Z. Dong, D. Arifin, Y. Hu, and C. Wang, J. Biomed. Mater. Res. A, 95A, 709 (2010).

T. Ciach, Int. J. Pharm., 324, 51 (2006).

J. Xie, L. K. Lim, Y. Phua, and C.-W. W. J. Hua, J. Colloid Interface Sci., 302, 103 (2006).

P. Perrot, “A to Z of Thermodynamics”, p.73, Oxford University Press, Kettering, 1998.

M. S. Silberberg, “Chemistry: The Molecular Nature of Matter and Change”, pp.205–206, McGraw-Hill, Boston, 2009.

I. V. Wesenbeeck, J. Driver, and J. Ross, Bull. Environ. Contam. Toxicol., 80, 315 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faramarzi, AR., Barzin, J. & Mobedi, H. Effect of solution and apparatus parameters on the morphology and size of electrosprayed PLGA microparticles. Fibers Polym 17, 1806–1819 (2016). https://doi.org/10.1007/s12221-016-6685-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-016-6685-3