Abstract

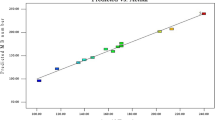

This study reports on the modeling and optimization of the iodine number of activated carbon fiber (ACF), using response surface methodology (RSM) based on the full factorial design (FFD). The individual and the interaction effects of the effective factors such as activation temperature (800, 900 and 1000 °C), time (1, 2 and 3 h), and activator type (KOH and NaOH) on the iodine number of the ACF were investigated in the optimization section. The FFD analysis confirmed that activation temperature and time were the main significant variables affecting the iodine number. High regression coefficient between the variables and the iodine number (R 2=0.9170) indicates excellent evaluation of experimental data by quadratic polynomial model. The RSM model predicted the 1028 value of the highest iodine number at conditions of 920 °C activation temperature, and 2.20 h of the time with used KOH for activator in activation process. The obtained FFD results confirmed that the selected RSM model presented acceptable performance for evaluating the involved factors and prediction of the ACF iodine number. The ACF produced under optimized conditions was characterized by pore structure analysis, scanning electron microscopy (SEM), and N2 adsorption/desorption isotherm. The obtained results showed that the produced ACF has developed porous structure and fibrous shape.

Similar content being viewed by others

References

Y. Yang, Z. M. Hua, X. Gang, and J. Z. Xiong, J. Porous. Mat., 18, 379 (2011).

E. Ekrami, F. Dadashian, and M. Soleimani, Fiber. Polym., 15, 1855 (2014).

A. L. Solano, M. A. L. Rodenas, J. P. M. Lozar, M. Kunowsky, and A. J. R. Anaya, Int. J. Energy, Environ. Econ., 20, 59 (2012).

V. T. Fernandez, J. M. M. Sanz, D. Montane, and V. Fierro, J. Chem. Eng. Data, 54, 2216 (2009).

R. Hilton, P. Bick, A. Tekeei, E. Leimkuehler, P. Pfeifer, and G. J. Suppes, Ind. Eng. Chem. Res., 51, 9129 (2012).

J. A. M. Agullo, B. C. Moore, D. C. Amoros, and A. L. Solano, Carbon, 42, 1367 (2004).

H. Y. Hsiao, C. M. Huang, M. Y. Hsu, and H. Chen, Sep. Purif. Technol., 82, 19 (2011).

W. Shen, S. Zhang, Y. He, J. Li, and W. Fan, J. Mater. Chem., 21, 14036 (2011).

M. Li, Y. Chen, Z. H. Huang, and F. Kang, J. Nanomater., 2014, 204172 (2014).

B. Xu, F. Wu, R. Chen, G. Cao, S. Chen, and Y. Yang, J. Power Sources, 195, 2118 (2010).

M. Wu, Q. Zha, J. Qiu, Y. Guo, H. Shang, and A. Yuan, Carbon, 42, 205 (2004).

A. T. Kalashnik, T. N. Smirnova, O. P. Chernova, and V. V. Kozlov, Polym. Sci., Ser. A, 52, 1233 (2010).

J. A. M. Agullo, B. C. Moore, D. C. Amoros, and A. L. Solano, Microporous Mesoporous Mat., 101, 397 (2007).

N. Yusof, A. F. Ismail, D. Rana, and T. Matsuura, Mater. Lett., 82, 16 (2012).

O. Ioannidou and A. Zabaniotou, Renew. Sust. Energ. Rev., 11, 1966 (2007).

A. Rabbi, K. Nasouri, H. Bahrambeygi, A. M. Shoushtari, and M. R. Babaei, Fiber. Polym., 13, 1007 (2012).

H. Bahrambeygi, N. Sabetzadeh, A. Rabbi, K. Nasouri, A. M. Shoushtari, and M. R. Babaei, J. Polym. Res., 20, 72 (2013).

K. Nasouri, H. Bahrambeygi, A. Rabbi, A. M. Shoushtari, and A. Kaflou, J. Appl. Polym. Sci., 126, 127 (2012).

K. Nasouri, A. M. Shoushtari, and M. Khamforoush, Fiber. Polym., 14, 1849 (2013).

D. C. Montgomery, “Design and Analysis of Experiments”, 8th ed., pp.19–47, Wiley, New York, 2008.

R. H. Myers, D. C. Montgomery, and C. M. A. Cook, “Response Surface Methodology: Process and Product Optimization Using Designed Experiments”, 3rd ed., pp.71–819, Wiley, New York, 1995.

N. M. Haimour and S. Emeish, Waste Manage., 26, 651 (2006).

T. C. Chandra, M. M. Mirna, J. Sunarso, Y. Sudaryanto, and S. Ismadji, J. Taiwan Inst. Chem. Eng., 40, 457 (2009).

S. Aber, A. Khataee, and M. Sheydaei, Bioresource Technol., 100, 6586 (2009).

J. W. Kim, M. H. Sohn, D. S. Kim, S. M. Sohn, and Y. S. Kwon, J. Hazard. Mater., 85, 301 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maddah, B., Nasouri, K. Fabrication of high surface area PAN-based activated carbon fibers using response surface methodology. Fibers Polym 16, 2141–2147 (2015). https://doi.org/10.1007/s12221-015-5514-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-015-5514-4