Abstract

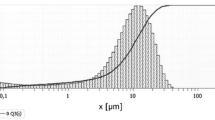

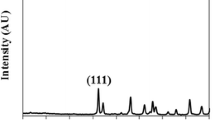

The clam shell (CS) waste was first modified by furfural and hydrochloric acid to prepare fillers FCS and ACS, which were then used as fillers in polypropylene (PP), as well as the commercial calcium carbonate (CC). These fillers were characterized and analyzed by means of X-ray diffraction (XRD), atomic force microscopy (AFM), particle size analyzer, Fourier transformed infrared spectroscopy (FTIR) and contact angle measurement. The mechanical and thermal properties of PP composites were investigated as well. XRD analysis indicated that the major crystalline phase of CC was calcite; of shell waste derived fillers, calcite and aragonite. The CC was fully hydrophobic, while the shell derived fillers were amphiphilic. Mechanical property studies showed that the incorporation of FCS played the role mainly of toughening the PP; of CC, CS and ACS, that of reinforcing. The optimum filler contents of CS, ACS and FCS could reach 5, 7 and 15 wt.%, respectively, to obtain a good balance between fracture toughness and stiffness of the PP composites. Polarized optical microscopy (POM) observation indicated that the inclusion of these fillers could promote the heterogeneous nucleation of PP.

Similar content being viewed by others

References

S. Rimdusit, W. Smittakorn, S. Jittarom, and S. Tiptipakorn, Eng. J., 15, 17 (2011).

M. Sadeghi and A. Esfandiari, Mater. Sci. Technol., 46, 695 (2012).

Z. Zhang, C. Wang, Y. Meng, and K. Mai, Compos. Part A-Appl. S., 43, 189 (2012).

W. C. J. Zuiderduin, C. Westzaan, J. Huétink, and R. J. Gaymans, Polymer, 44, 261 (2003).

P. Eteläaho, S. Haveri, and P. Järvelä, Polym. Compos., 32, 464 (2011).

B. Rotzinger, Polym. Degrad. Stabil., 91, 2884 (2006).

M. Rahail Parvaiz, P. A. Mahanwar, S. Mohanty, and S. K. Nayak, J. Miner. Mater. Charact. Eng., 9, 985 (2010).

A. Ariffin, A. S. Mansor, S. S. Jikan, and Z. A. Mohd. Ishak, J. Appl. Polym. Sci., 108, 3901 (2008).

V. Mittal, J. Thermoplast. Compos., 20, 575 (2007).

A. Esfandiari, H. Nazokdast, A. S. Rashidi, and M. E. Yazdanshenas, J. Appl. Sci., 8, 545 (2008).

A. Esfandiari, Fiber. Polym., 9, 48 (2008).

A. Esfandiari, Worl. Appl. Sci. J., 3, 470 (2008).

M. Sadeghi and A. Esfandiari, Fiber. Polym., 14, 556 (2013).

A. Zarafshan, S. Zarafshan, and A. H. Esfandiari, Mater. Plast., 48, 285 (2011).

Z. T. Yao, T. Chen, H. Y. Li, M. S. Xia, Y. Ye, and H. Zheng, J. Hazard. Mater., 262, 212 (2013).

M. Suzuki, S. Sakuda, and H. Nagasawa, Biosci. Biotechnol. Biochem., 71, 1735 (2007).

S. Sudo, T. Fujikawa, T. Nagakura, T. Ohkubo, K. Sakaguchi, M. Tanaka, K. Nakashima, and T. Takahashi, Nature, 387, 563 (1997).

M. H. Chong, B. C. Chun, Y. C. Chung, and B. G. Cho, J. Appl. Polym. Sci., 99, 1583 (2006).

Z. D. Lin, Z. X. Guan, C. Chen, and B. F. Xu, Thermochim. Acta, 551, 149 (2013).

H. Y. Li, Y. Q. Tan, L. Zhang, Y. X. Zhang, Y. H. Song, Y. Ye, and M. S. Xia, J. Hazard. Mater., 217–218, 256 (2012).

C. M. Chan, J. Wu, J. X. Li, and Y. K. Cheung, Polymer, 43, 2981 (2002).

S. C. Tjong, “Polymer Composites with Carbonaceous Nanofillers: Properties and Applications”, John Wiley & Sons Weinheim, 2012.

D. Yu and B. Debes, Mat. Sci. Eng. A-Struct., 527, 1617 (2010).

H. Z. Yan and Y. Chen, Iran. Polym. J., 19, 791 (2010).

S. Gopi and V. K. Subramanian, Ind. J. Chem., 52, 342 (2013).

B. Chen, J. H. Fan, J. Wang, X. Peng, and X. L. Wu, J. Metastable Nanocryst. Mater., 23, 83 (2005).

S. D. Cifrulak, Am. Mineral., 55, 815 (1970).

S. W. Lee, Y. N. Jang, and J. C. Kim, Evid-Based Compl. Alt., 2011, 1 (2011).

C. Linga Raju, K. V. Narasimhulu, N. O. Gopal, J. L. Rao, and B. C. V. Reddy, J. Mol. Struct., 608, 201 (2002).

L. N. Zhao, J. D. Feng, and Z. C. Wang, Sci. China Ser B., 52, 924 (2009).

S. B. Jeong, Y. C. Yang, Y. B. Chae, and B. G. Kim, Mater. Trans., 50, 409 (2009).

L. C. Li and Y. Zhang, Adv. Mater. Res., 79–82, 1967 (2009).

H. Y. Li, T. Chen, H. Y. Zhang, Z. T. Yao, L. Zhang, L. Pan, Y. Ye, and M. S. Xia, J. Chinese Ceram. Soc., 40, 1671 (2012).

H. Y. Li, H. Y. Zhang, L. Pan, T. Chen, L. Zhang, Y. Ye, and M. S. Xia, J. Funct. Mater., 43, 1519 (2012).

H. Murase and T. Fujibayashi, Prog. Org. Coatings, 31, 97 (1997).

Y. I. Yun, K. S. Kim, S. J. Uhm, B. B. Khantua, K. Cho, J. K. Kim, and C. E. Park, J. Adhesion Sci. Tech., 18, 1279 (2004).

N. Ayrilmis and A. Kaymakci, Ind. Crop. Prod., 43, 457 (2013).

A. K. Bledzki, A. A. Mamun, M. Lucka-Gabor, and V. S. Gutowski, Express Polym. Lett., 2, 413 (2008).

A. K. Bledzki and J. Gassan, Prog. Polym. Sci., 24, 221 (1999).

N. Ayrilmis, S. Jarusombuti, V. Fuengvivat, P. Bauchongkol, and R. H. White, Fiber. Polym., 12, 919 (2011).

N. Ayrilmis, A. Kaymakci, T. Akbulut, and G. M. Elmas, Compos. Part B-Eng., 47, 150 (2013).

Y. W. Leong, M. B. Abu Bakar, Z. A. Mohd Ishak, and A. Ariffin, Polym. Degrad. Stabil., 83, 411 (2004).

G. Wang, X. Y. Chen, R. Huang, and L. Zhang, J. Mater. Sci. Lett., 21, 985 (2002).

J. I. Weon, K. T. Gam, W. J. Boo, H. J. Sue, and C. M. Chan, J. Appl. Polym. Sci., 99, 3070 (2006).

Q. X. Zhang, Z. Z. Yu, X. L. Xie, and Y. W. Mai, Polymer, 45, 5985 (2004).

T. Guo, L. S. Wang, A. Q. Zhang, and T. M. Cai, J. Appl. Polym. Sci., 97, 1154 (2005).

E. Piorkowska and G. C. Rutledge, “Handbook of Polymer Crystallization”, John Wiley & Sons Weinheim, 2013.

J. S. Ma, S. M. Zhang, Z. N. Qi, G. Li, and Y. L. Hu, J. Appl. Polym. Sci., 83, 1978 (2002).

S. Y. Lee, I. A. Kang, G. H. Doh, W. J. Kim, J. S. Kim, H. G. Yoon, and Q. H. Wu, Express Polym. Lett., 2, 78 (2008).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yao, Z., Xia, M., Ge, L. et al. Mechanical and thermal properties of polypropylene (PP) composites filled with CaCO3 and shell waste derived bio-fillers. Fibers Polym 15, 1278–1287 (2014). https://doi.org/10.1007/s12221-014-1278-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-1278-5